Product Description:

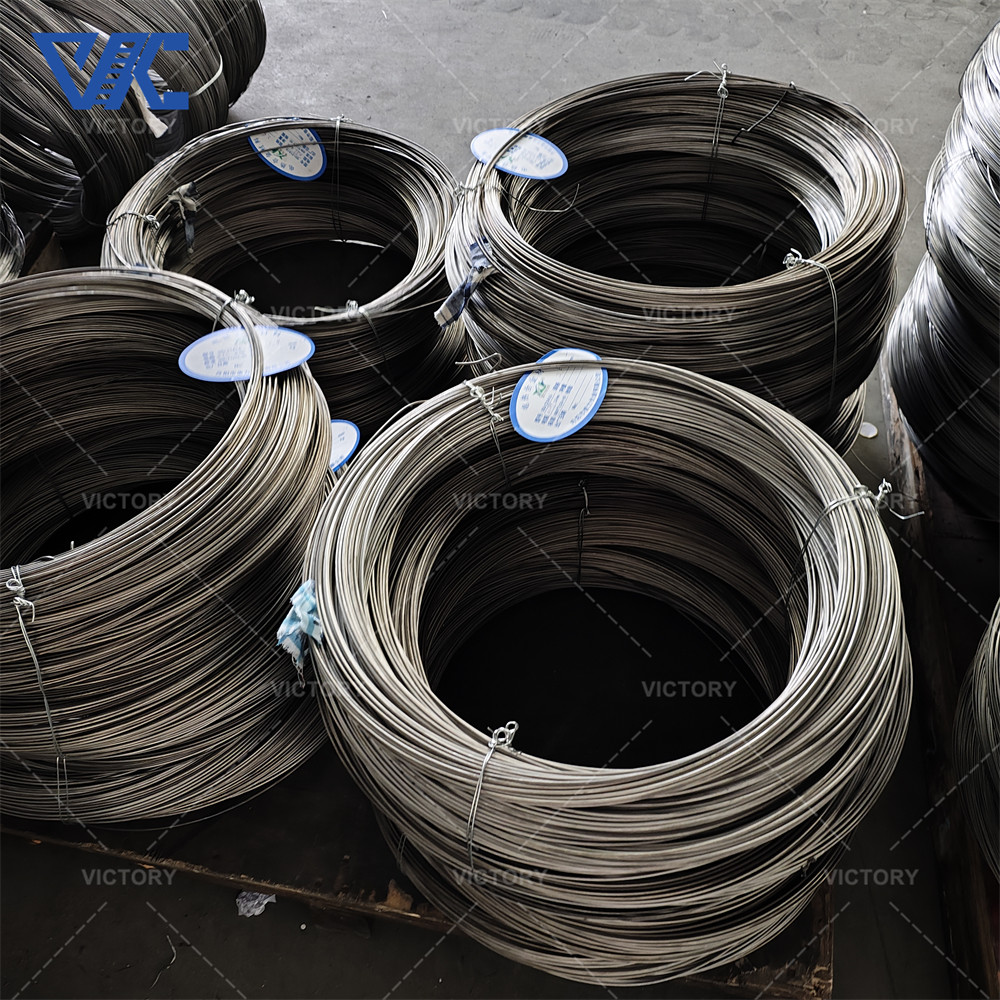

Pure nickel wire is a wire-shaped product made of high-purity nickel material. It has outstanding performance characteristics, including excellent corrosion resistance, high temperature stability, good electrical conductivity and mechanical strength.

Pure nickel wire is available in a wide range of diameters and can be customized according to requirements. It is widely used in electronics, electrical, heating, automotive, chemical and medical fields. Pure nickel wire can be used to manufacture resistors, inductors, heaters, fuel nozzles, medical equipment and other products. It can also be used in chemical equipment, catalyst supports and electrolytic cells. Manufacturers can customize the diameter, length, chemical composition, surface treatment and other characteristics of pure nickel wire according to customer requirements. In addition, pure nickel wire has excellent corrosion resistance and remains stable in high temperatures and corrosive environments, while having a low linear expansion coefficient and good resilience. Pure nickel wire provides a reliable solution to meet the high quality and customization needs of various industries.

Factors affecting tensile strength:

Generally speaking, as the temperature increases, the tensile strength of pure nickel wire will decrease, and as the temperature decreases, the tensile strength will increase. This is because temperature changes will affect factors such as the material's lattice structure, interactions between atoms, and dislocation motion, thereby affecting the material's mechanical properties.

Specifically, the influence of temperature on the tensile strength of pure nickel wire mainly includes the following aspects:

- Thermal expansion: As the temperature increases, pure nickel wire will undergo thermal expansion, resulting in changes in the lattice structure and an increase in atomic spacing. This may lead to easier movement of grain boundary slip and dislocations, thereby reducing the tensile strength of the material.

- Lattice changes: At high temperatures, the lattice structure of pure nickel wire may undergo changes, such as an increase in the lattice constant or the movement of grain boundaries. These changes can lead to changes in the material's mechanical properties, including a reduction in tensile strength.

- Dynamic recovery: At high temperatures, dislocation movement of pure nickel wire occurs more easily, thereby increasing the material's dynamic recovery capability. This can result in a reduction in the tensile strength of the material.

It should be noted that the tensile strength changes of pure nickel wire in different temperature ranges may have different trends. In addition, the reduction in tensile strength does not mean that pure nickel wire cannot be used in high temperature environments, but that appropriate materials and design measures need to be selected based on specific application requirements and temperature conditions.

Factors affecting tensile strength:

The tensile strength of pure nickel wire is affected by many factors, including but not limited to the following aspects:

- Temperature: As mentioned earlier, temperature has a significant impact on the tensile strength of pure nickel wire. Generally speaking, as the temperature increases, the tensile strength of pure nickel wire will decrease, and as the temperature decreases, the tensile strength will increase.

- Grain size: The grain size of pure nickel wire also affects its tensile strength. Smaller grain size usually means a material has higher strength, because small grain size can hinder the movement of dislocations. On the contrary, larger grain size may lead to easy slippage of dislocations, thus reducing the tensile strength.

- Alloying elements: The tensile strength of pure nickel wire can be changed by adding other elements through alloying. For example, adding a certain amount of chromium, molybdenum, iron and other elements can improve the tensile strength and hardness of pure nickel wire.

- Cold working deformation: Cold working deformation can improve the tensile strength of pure nickel wire by increasing its dislocation density. Cold working introduces more dislocations, increasing the material's strength. However, excessive cold working may lead to increased brittleness and thus reduced tensile strength.

- Grain boundaries and impurities: The grain boundaries and impurities of pure nickel wire will also affect its tensile strength. The interaction of grain boundary structure and dislocations may lead to localized stress concentrations, thereby reducing tensile strength. In addition, the presence of impurity elements may affect the lattice structure and interactions of pure nickel wire, thereby affecting its tensile strength.

- Processing technology: The processing technology of pure nickel wire, such as annealing, cold drawing, heat treatment, etc., will also affect its tensile strength. Appropriate processing techniques can improve the lattice structure and dislocation density, thereby increasing tensile strength.

Technical Parameters:

| Specifications | Values |

| Product name | Pure Nickel Wire |

| Ni(min) | 99% |

| Grade | N4,N6,Ni200,Ni201 |

| Size | 0.025-10mm |

| Shape | Wire |

| Hardness | S,1/4H,1/2H,3/4H,H |

| Melting Point | 1435-1446°C |

| Elongation (≥ %) | 35% |

| Resistance (μΩ.m) | 15 |

| Application | Industry,Electronic |

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.8 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | ≥99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | ≥99.2 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

For more details, pls directly contact us.

Features:

- Product Name: Nickel Wire

- Material: Ni

- Standard: ASTM B164, DIN 17752, JIS NW2200

- Ultimate Strength (≥ MPa): 462

- Product name: Pure Nickel Wire

- Grade: N4,N6,Ni200,Ni201

- Product Features:

- Pure nickel wire with a material of Ni

- Complies with ASTM B164, DIN 17752, JIS NW2200 standards

- Ultimate strength of at least 462 MPa

- Available in various grades: N4, N6, Ni200, Ni201

- Diameter options: 0.025 mm, 0.05 mm, 0.1 mm

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

FAQ:

What is the diameter range of pure nickel wire?

Pure nickel wire can range in diameter from a few microns to several millimeters, depending on application requirements.

Can pure nickel wire be used in resistor manufacturing?

Yes, pure nickel wire is often used in the manufacture of resistors, with stable resistance characteristics and good high temperature resistance.

What is the tensile strength of pure nickel wire?

The tensile strength of pure nickel wire usually ranges from 400 MPa to 800 MPa, depending on the diameter and heat treatment conditions.