Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

ERNiCrMo-13 welding wire not only has good corrosion resistance and

high temperature resistance, but also has high oxidation resistance

and thermal expansion coefficient adaptability. It plays an

important role in the chemical industry and in the manufacturing of

equipment in corrosive environments.

ERNiCrMo-13 welding wire excels in corrosion resistance. It can

resist the erosion of various corrosive media, including acids,

alkalis, salts, etc. Especially in high sulfide environments, it

exhibits excellent sulfide corrosion resistance and effectively

resists corrosion caused by sulfides such as hydrogen sulfide.

Therefore, it is widely used in scenarios such as chemical, oil and

gas industries that need to face high sulfide environments.

In addition, ERNiCrMo-13 welding wire also has excellent high temperature resistance. It can maintain the stability and durability of welded joints in high temperature environments. It can resist deformation and cracking caused by high-temperature oxidation and thermal stress, so it is widely used in aerospace, nuclear energy industry, high-temperature equipment manufacturing and other fields.

Welding of aerospace engine components: ERNiCrMo-13 welding wire is widely used in the welding of key components of aerospace engines, such as turbine blades, turbine disks, combustion chambers and gas turbines. These components work in high temperature, high pressure and corrosive environments. ERNiCrMo-13 welding wire can provide excellent high temperature resistance and corrosion resistance, ensuring the reliability and long life of the welded joints.

Aerospace vehicle structural welding: ERNiCrMo-13 welding wire can be used for aerospace vehicle structural welding, such as spacecraft shells, wing body connections and rudder surfaces, etc. These welded joints require high temperature strength, corrosion resistance and good weld performance. ERNiCrMo-13 welding wire can meet these requirements and ensure the structural integrity and safety of spacecraft in extreme environments.

Aerospace equipment repair: ERNiCrMo-13 welding wire is also used in the repair and repair of aerospace equipment. When critical components of an aircraft or engine are damaged or cracked, using ERNiCrMo-13 welding wire for repair welding can restore its original performance and structural integrity and extend the service life of the equipment.

In short, ERNiCrMo-13 welding wire is widely used in the aerospace field for welding of aerospace engine components, structural welding of aerospace vehicles, and equipment maintenance and repair. Its high temperature strength, corrosion resistance and welding performance make it one of the important welding materials in the aerospace field.

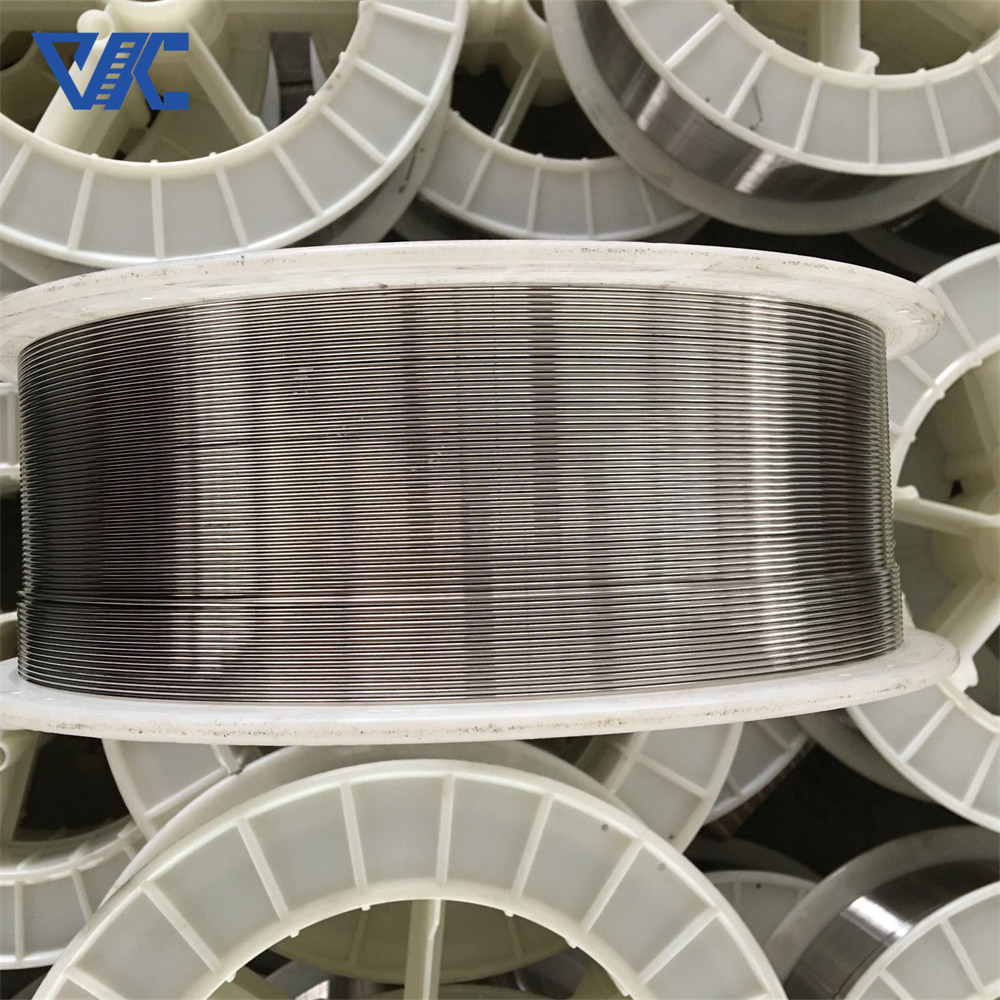

| MIG | (15kg/spool), | Size |

| 0.8 1.2 2.4 3.2mm | ||

| TIG | (5kg/box),Strip |

ERNiCrMo-13

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Al | Ti | Cr | Nb+Ta | Mo | V | W | Rest |

| 0.01 | 0.5 | 1.5 | 0.015 | 0.005 | 0.1 | N/A | Rest | 0.3 | 0.1-0.4 | N/A | 22-24 | 1.8-2.5 | 15-16 | N/A | N/A | ≤0.50 |

In the aerospace field, ERNiCrMo-13 welding wire has the following advantages:

1. High-temperature performance: Many components in aerospace applications need to operate in extreme high-temperature environments, such as aircraft engines and gas turbines. ERNiCrMo-13 welding wire can maintain the stability and strength of welded joints at high temperatures and resist deformation and cracking caused by high-temperature oxidation and thermal stress.

2. Corrosion resistance: Aerospace equipment faces erosion from various corrosive media, including acids, salts and alkalis. ERNiCrMo-13 welding wire has excellent corrosion resistance and can resist the erosion of these corrosive media, ensuring the long-term stability of welded joints in harsh environments.

3. High strength and toughness: Aerospace equipment needs to withstand complex stresses and loads, so welded joints need to have high strength and good toughness. ERNiCrMo-13 welding wire has excellent mechanical properties and is able to provide reliable connections and withstand large loads in areas of stress concentration.

3. Reliability and safety: The aerospace industry has extremely high requirements on the reliability and safety of welded joints. ERNiCrMo-13 welding wire is suitable for a variety of welding methods and can be matched with different base materials and welding joint designs. By optimizing the welding process and controlling parameters, the quality of welded joints can be ensured and the reliability and safety of aerospace equipment can be improved.

4. Process flexibility: ERNiCrMo-13 welding wire is suitable for a variety of welding methods, such as TIG (argon arc welding), MIG (inert gas shielded welding), etc. This makes the welding process more flexible and able to adapt to different welding needs and process requirements.

To sum up, ERNiCrMo-13 welding wire has multiple advantages in the aerospace field such as high temperature resistance, corrosion resistance, high strength, toughness, reliability and safety. This makes it an important material choice in aerospace equipment welding, ensuring the performance and reliability of aerospace equipment.

Looking for high quality and reliable nickel weld wire? Look no further than Victory's ERNiCrMo-13 welding wire. Made with high quality nickel material, this wire is perfect for all your welding needs.

At Victory, we understand that each project is unique and requires specific welding solutions. That's why we offer customization services for our nickel welding wire. We can tailor the wire according to your specific needs and requirements, ensuring the best possible results for your project.

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

There are some things to consider when using ERNiCrMo-13 welding wire:

1. Clean the welding surface: Before welding, make sure the surface of the welded joint is clean, free of oil, dust and other contaminants. Use appropriate cleaners and methods to clean welding surfaces to ensure good welding quality and strength.

2. Control welding parameters: Control welding parameters such as welding current, voltage, speed and preheating temperature according to specific welding requirements and applications. Make sure to select appropriate welding parameters to achieve ideal welding results and performance.

3. Prevent oxidation: ERNiCrMo-13 welding wire is sensitive to oxygen and easily oxidized. During the welding process, appropriate protective measures should be taken, such as using inert gas (such as argon) for inert gas shielded welding, to prevent oxidation and quality loss of the welding wire.

4. Avoid overheating: Overheating can cause cracks and deformation of welded joints. Control the welding heat input and avoid excessively high temperatures and excessively long welding times to reduce the impact of the heat-affected zone and ensure the strength and stability of the welded joint.

5. Pay attention to safety: During the welding process, follow safe operating procedures and wear appropriate personal protective equipment, such as gloves, goggles, and protective clothing, to protect your own safety.

Q: Does the welding joint of ERNiCrMo-13 welding wire require

subsequent heat treatment?

A: Depending on specific requirements, the welded joints of

ERNiCrMo-13 wire may require subsequent heat treatment to obtain

optimal performance and microstructure.

Q: What kind of gas protection measures need to be taken during the

welding process of ERNiCrMo-13 welding wire?

Answer: ERNiCrMo-13 welding wire usually requires the use of inert

gas (such as argon) for gas protection during the welding process.

Q: Is it possible to customize ERNiCrMo-13 welding wire?

Answer: Yes, ERNiCrMo-13 welding wire can be customized according

to customer requirements to meet specific welding needs.

|  |