Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

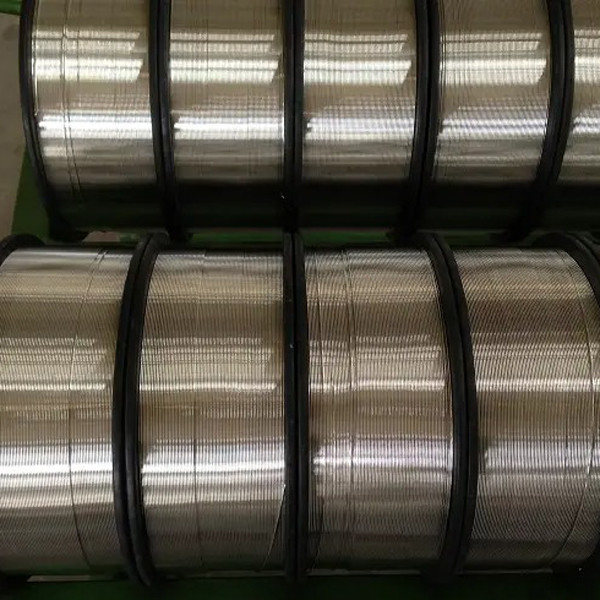

.0mm 1.2mm 1.6mm Erni-1 Pure Nickel Wire Ni200 MIG TIG Welding Wire

Nickel welding wire is a metal welding material commonly used in the welding field, including various brands, such as ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-7 and ERNiCr-3. These wires are available in different alloy compositions and welding properties to meet the needs of a variety of specific welding applications.

ERNiCrMo-3 is a high-alloy nickel welding wire suitable for welding high-alloy steel and nickel alloys. It has good corrosion resistance and high temperature stability, and is widely used in equipment and pipeline welding in the chemical, petroleum and petrochemical industries.

ERNiCrMo-4 is a nickel-based alloy welding wire suitable for welding stainless steel and nickel-based alloys. It has excellent corrosion resistance and high temperature performance and is commonly used in chemical, marine engineering and nuclear industries.

ERNiCrMo-13 is a high-alloy nickel welding wire commonly used for welding corrosion-resistant alloys, high-temperature alloys and acid-resistant stainless steel. It has excellent corrosion resistance and high temperature strength.

ERNiCrFe-7 is a nickel-iron-based alloy welding wire suitable for welding stainless steel, alloy steel and high-temperature alloys. It has good corrosion resistance and high temperature performance.

ERNiCr-3 is a common nickel welding wire suitable for welding stainless steel, nickel alloys and other high temperature alloys. It is widely used in aerospace, petrochemical, nuclear energy and other fields.

The selection of suitable nickel welding wire grades should be determined based on specific welding requirements, metal materials and process conditions. When using nickel wire, refer to the manufacturer's specification sheet and technical literature to ensure correct welding parameters and operating procedures to obtain a quality weld joint and performance that meets the needs of your specific application.

| C | Si | Mn | Cr | P | Ni |

| ≤0.01 | ≤0.2 | ≤0.5 | 22.0-24.0 | ≤0.015 | Rem |

| Al | Mo | Fe | Cu | S | Co |

| 0.10-0.40 | 15.0-16.50 | ≤0.5 | ≤0.1 | <0.01 | <0.20 |

| Typical Welding Parameters | |||||

| Diameter | Process | Volt | Amps (flat) | Amps (V/OH) | |

| inch | (mm) | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | Spray Transfer 100% Argon |

| 0.045 | 1.2 | GMAW | 28-32 | 180-220 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GMAW | 29-33 | 200-250 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | GTAW | 15-20 | 120-175 | 100% Argon |

| 1/8 | 3.17 | GTAW | 15-20 | 150-220 | 100% Argon |

| Tensile Strength | 109 Ksi | 790 MPA |

| Yield Strength | 68 Ksi | 470 MPA |

| Elongation | 40-45% | |

| Density g/cm3 | 8.60 g/cm3 | |

| Melting Point ℃ | 1300-1360℃ | |

| Coefficient of Expansion. 21-93 Co, μm/m * Co | 11.90 |

|  |