Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

Introduction:

Aluminum welding wire is a filler metal wire used for welding aluminum alloy materials. It has lightweight, high strength, good thermal and electrical conductivity, and excellent corrosion resistance. Aluminum welding wire is designed with a special alloy composition to provide the required mechanical properties and corrosion resistance during the welding process. It is widely used in many fields such as aerospace, automobile manufacturing, shipbuilding, chemical equipment, electronic products, and daily necessities. .

Common brands of aluminum welding wire include but are not limited to the following:

ER1100 (HS301): Pure aluminum welding wire with an aluminum content greater than 99.5%. It is suitable for welding aluminum equipment in the chemical industry. It has good corrosion resistance and high thermal and electrical conductivity.

ER4043: Aluminum-silicon alloy welding wire, containing about 5% silicon, suitable for welding cast aluminum alloys, with low melting point and good fluidity, suitable for ships, motorcycles, chemical industry, food processing, sports equipment and other fields.

ER4047: Aluminum-silicon alloy welding wire, containing about 12% silicon, suitable for welding or surfacing light alloy processing industry. The low melting point and good fluidity make the welding deformation of the base metal very small.

ER5356: Aluminum-magnesium alloy welding wire, containing about 5% magnesium. It is a versatile general-purpose welding material, suitable for welding or surface surfacing of cast and forged aluminum alloys containing 5% magnesium. It has high strength, good forgeability and Corrosion resistance.

Parameter:

pure aluminum welding wire: ER1100,ER1070

aluminum-copper alloy welding wire: ER2319

aluminum-silicon alloy welding wire: ER4043,ER4047,ER4145

aluminum-magnesium alloy welding wire: ER5087,ER5356,ER5183,ER5554,ER5556,ER5754

aluminum-manganese alloy welding wire: ER3003,ER3103

| Packing type | Size specification | Packing tool | Weight |

| MIG wire (Packing in spool) | 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm | D270mm plastic spool | 7kg |

| D300mm plastic spool | 9kg | ||

| D300mm metal spool | 7kg | ||

| 0.8mm, 0.9mm,1.0mm,1.2mm | D200mm plastic spool | 2kg | |

| D100mm plastic spool | 0.5kg | ||

| TIG rod (Packing in straight 1000mm) | 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm,4.0mm, 5.0mm, 6.0mm | 1000mm length carton | 10kg |

| 1000mm length carton | 5kg | ||

| 1000mm length plastic box | 2.5kg | ||

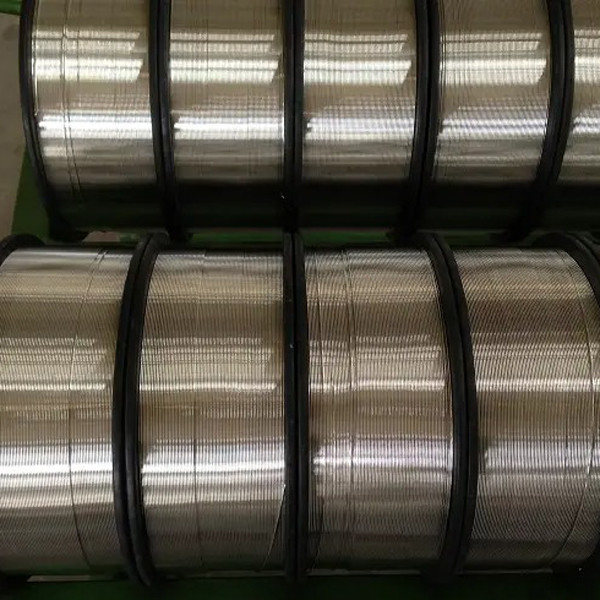

| Coil wire (Packing in coil) | 2.4mm, 3.0mm, 3.2mm, 4.0mm | D450mm coil | 20kg |

| Drum wire (Packing in drum) | 1.0mm, 1.2mm, 1.6mm | D520mm drum | 75kg |

Feature:

Application:

|  |

Q&A:

Q: What are the main components of aluminum welding wire?

A: The main component of aluminum welding wire is aluminum, and may also contain other elements, such as silicon, iron, copper, manganese, magnesium, zinc, titanium, etc. The addition of these elements can improve the welding performance and mechanical properties of the welding wire.

Q: What kind of protective gas is needed for aluminum welding wire?

A: The most commonly used protective gas when welding aluminum wire is argon, because argon can provide an oxygen-free welding environment and prevent oxidation of the weld.

Q: Why is it recommended to use the push gun method when welding aluminum wire?

A: It is recommended to use the push-gun method when welding aluminum. This is because the aluminum welding wire is soft, and the push-gun method can help reduce problems that may occur during wire feeding, such as wire breakage or deformation.