Xinxiang AAREAL Machine Co.,Ltd |

|

Overview of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy is a new screening machine which is developed mainly aiming at screening of bulky urea and fertilizer, graphite, powder metallurgy, alumina, limestone, garnet sand also used widely for screening sugar, calcium carbonate powder, salt,activated carbon, seed, sand, stone powder, grain etc.

It is also well known as the gyratory screen, gyratory screener, gyratory separator, gyratory sifter, gyratory screening machine, Rotex screen, Rotex screening machine, Rotex separator, planar rotary screen, plane rotary screen, rotary flat sieve, flat screen, square precision screening machine, reciprocating screen etc.

Advantages of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

1. Automatic cleaning- Bouncing balls keep screen openings clean

and maintain efficiency and capacity.

2. Screen long service life- No vertical component avoid the impact

and damage of material to screen.

3. Top-class design -Mature technology, easy installation and

maintenance, convenient and quick screen replacement.

4. Customized order- multi- layer,different capacity and mesh size

can be customized according to customer's demand.

5. Quick Screen Changes-Quick release device is provided to take

down the net rack and replace the screen rapidly.

6. Full utilization of screen surface- Gyratory reciprocating

motion ensures material constantly contact with screen surface.

7. Environmentally Friendly- Fully enclosed structure,no dust

pollution,improve working conditions for operators as well.

8. Various sieving solution- Gyratory screen allows separations

with openings from 12mm to 325 mesh.

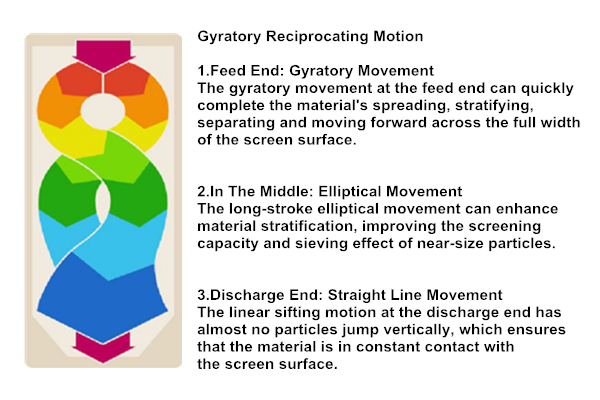

| Moving Trajectory | gyratory reciprocating motion: circular motion at feed end, elliptical motion at center, and linear motion at discharge end |

| Drive Device | general motor + pulley belt + exciter |

| Layers of Screen | 1~4 layers of screen available |

| Screen Size | 500*1500mm, 1000*2100mm, 1000*3000mm, 1500*3000mm, 1500*3600mm, 1800*3600mm, 1800*4000mm, 2000*5000mm etc. |

| Motor Brand | Siemens, or according to customer requirements |

| Spare Parts | the special screen, drive exciter, compensating clamps and clips are made by ourselves |

| Discharge Port | usually at the bottom of the machine, it can also be made at the back of the machine |

| Material | carbon steel, stainless steel, aluminium (optional) |

| Installation | floor seat installation, cable suspension installation |

| Mesh Cleaning Method | Use mesh cleaning balls to clean the screen mesh. Rubber ball, silicone ball, polyurethane ball etc. |

Working Principle of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

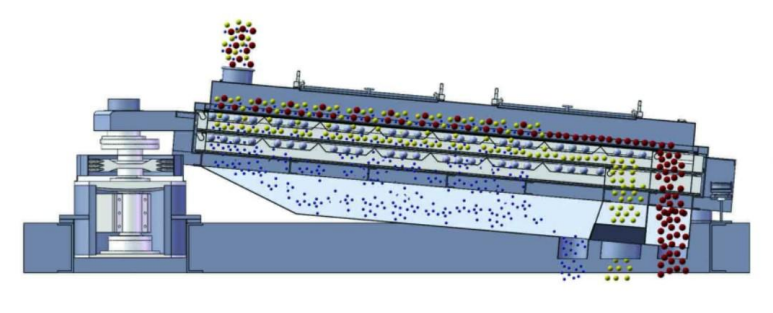

The AD model gyratory sifter is driven by an ordinary motor, this gyratory screening machine drives the eccentric wheel to do gyratory reciprocating motion.

The gyratory reciprocating motion of gyratory screen begins with a circular motion at the feed end, gradually diminishing along the length of the machine to elliptical movement in the middle, and finally to an almost straight-line motion at the discharge end.

Application of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

As one of new type and high standard screening equipment, gyratory screen can be used to screen of raw materials and bean curd in large scale grease factory, and screen or classify large granular urea, powder materials or granulated feed in feed mill. Also, it can be used for preliminary cleaning of raw material in feed mill as well as classifying intermediate products after regrinding in middle-sized feed mill. What's more, gyratory screen can be widely used to screen and classify materials or finished products for grain, sodium bicarbonate, large granular urea, urea granules, ceramsite, zirconia, reduced iron powder, barite, spice, plastic, mining industry, rubber, wood industry, plywood, medicine, sugar, mining, papermaking, chemical, refractory materials, building materials, activated carbon, food, PVC powder and other fine materials etc.. With the development of market circulation economy, it is increasing to be used in waste plastic industry to classify, and also can do size grading for materials with broken.

Technical Parameters of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

Layers | Model | Screen Surface Specification (W*L) (mm) | Screen Box Stroke (mm) | Motor | A (mm) | B (mm) | C (mm) | D (mm) | Weight (kg) | |

Power (kw) | Rotation Rate (rpm) | |||||||||

| 1 | AD-1014-1 | 1000*1400 | 63.5 | 1.5 | 960 | 2731 | 962 | 1168 | 1200 | 715 |

| AD-1021-1 | 1000*2100 | 63.5 | 1.5 | 960 | 3285 | 962 | 1156 | 1200 | 980 | |

| AD-1030-1 | 1000*3000 | 63.5 | 1.5 | 960 | 4484 | 1035 | 1194 | 1251 | 1200 | |

| AD-1521-1 | 1500*2100 | 63.5 | 1.5 | 960 | 3460 | 1003 | 1708 | 1759 | 1380 | |

| AD-1530-1 | 1500*3000 | 76 | 2.2 | 960 | 4232 | 1362 | 1778 | 1892 | 1340 | |

| AD-1536-1 | 1500*3600 | 76 | 5.5 | 960 | 5098 | 1352 | 1956 | 2048 | 2410 | |

| 2 | AD-1236-2 | 1200*3600 | 76 | 5.5 | 960 | 5263 | 1327 | 2464 | 2556 | 2020 |

| AD-1021-2 | 1000*2100 | 63.5 | 1.5 | 960 | 3743 | 1121 | 1308 | 1378 | 1400 | |

| AD-1030-2 | 1000*3000 | 76 | 4 | 960 | 4575 | 1317 | 1270 | 1546 | 1840 | |

| AD-1521-2 | 1500*2100 | 63.5 | 4 | 960 | 3728 | 1330 | 1781 | 1946 | 1710 | |

| AD-1836-2 | 1800*3600 | 76 | 7.5 | 960 | 5305 | 1500 | 2256 | 2459 | 3880 | |

| AD-1530-2 | 1500*3000 | 76 | 7.5 | 960 | 4765 | 1397 | 1956 | 2159 | 2780 | |

| AD-1536-2 | 1500*3600 | 76 | 7.5 | 960 | 5365 | 1368 | 2032 | 2019 | 3180 | |

3

| AD-1021-3 | 1000*2100 | 63.5 | 5.5 | 960 | 4854 | 1422 | 1435 | 1549 | 2150 |

| AD-1530-3 | 1500*3000 | 76 | 5.5 | 960 | 4765 | 1391 | 1956 | 2159 | 3200 | |

| AD-1836-3 | 1800*3600 | 76 | 7.5 | 960 | 5200 | 1500 | 2400 | 2500 | 4170 | |

| AD-2050-3 | 2000*5000 | 92 | 11 | 960 | 5400 | 2000 | 2750 | 2810 | 5500 | |

Installation of High Precision and High Yield Gyratory Screening Machine for Mining Metallurgy:

1. Seat Installation:

Forward Type

Direct Discharge Type

2. Cable Suspension Installation:

Cable Suspension Type

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com