Xinxiang AAREAL Machine Co.,Ltd |

|

316L Vibro Screen Machine Low Profile Direct Discharge Industrial Vibrating Screen

Product Introduction of Low Profile Direct Discharge Vibrating Screen Machine:

The low profile direct discharge vibrating screen machine is is a

powerful high-efficient machine that compacts high capacity

scalping for both wet and dry materials. It is also called

flow-thru separator, compact sieve, safety screeners, control

sieves, low-profile vibrating sieve, low profile separator, inline

vibrating screen etc.

The inline vibro screen use two vibratory motors mounted on opposing exterior sidewalls of the unit, reducing minimum height requirements significantly. This inline vibro screen innovation also enables the bottom outlet to be located directly below the top inlet, allowing material to fall vertically through the screen at high rates. The low profile separator has a single vertically mounted motor to generate a sifting motion across the screen plane. The inline low profile vibro screen offers high capacities of wet or dry scalping in a low headroom design. Available from 600mm to 2100mm in diameter. This range of separators perfect for all processing industries and application like prepacking screening, bulk bag unloading and screening of raw ingredients.

Features of Low Profile Direct Discharge Vibrating Screen Machine:

1. Low installation cost.

2. Less plant area with higher outputs.

3. Less manpower as easy to operate.

4. Adjustable motor mounting angle.

5. Personalised inlets and outlets.

6. Motor force for maximizing screening efficiency and capacity.

7. Hassle-free cleaning and maintenance in place without

disassembly.

Some Important Information You May Concern About Low Profile Direct Discharge Vibrating Screen Machine:

| Alternative Name | flow-thru separator, compact sieve, check screening machine, safety screener, control sieve, inline vibrating sieve etc. |

| Motor | single vibrating motor, dual vibrating motors (optional) |

| Height | 500mm or less (such as 300mm) |

| Mesh Debling System | ultrasonic deblinding system, bouncing balls, rotary brush etc. |

| Layers of Screen | 1~2 layers of screens (multiple layers can be customized according to the specific situation) |

| Diameter | 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2100mm etc. |

| Discharge Port | the discharge port for fine particles are at the bottom of the machine |

| Purpose | suitable for materials safety screening with less oversize particles |

| Machine Shape | round, rectangular |

| Damping Spring | steel spring, rubber spring |

| Application | flour, starch, milk powder, additives, instant noodles, noodles, snacks, solid drinks etc. |

| Voltage | three-phase/380V, 415V, 440V etc. |

Working Principle of Low Profile Direct Discharge Vibrating Screen Machine:

The low profile flow-thru vibrating separator uses vertical vibration motor as excitation source. This motor is equipped on both sides with an eccentric hammer which functions to transfer the rotation movement of motor to horizontal, vertical and inclined motions. And the hammer then delivers the motions to screen surface for sifting. At present, rotary sieve machine is widely applied in pharmaceutical, foodstuff and other industries.

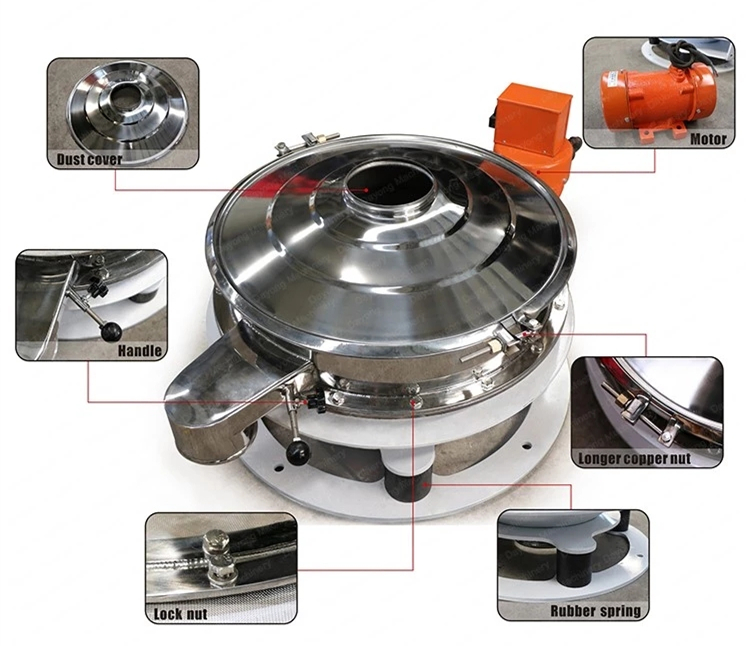

Structure of Low Profile Direct Discharge Vibrating Screen Machine:

Technical Parameters of Low Profile Direct Discharge Vibrating Screen Machine:

| Model | 400 | 600 | 800 | 1000 | 1200 | 1300 | 1500 |

| Power | 0.1kw | 0.1kw | 0.1kw | 0.2kw | 0.2kw | 0.2kw | 0.4kw |

| Screen Diameter | 350mm | 550mm | 750mm | 920mm | 1005mm | 1120mm | 1420mm |

Note: the data above are for reference only, and our company reserves the right to modify the data.

Some Types for Low Profile Direct Discharge Vibrating Screen Machine:

Application of Low Profile Direct Discharge Vibrating Screen Machine:

1. Chemical industry: resin powder, palette, washing powder, paint,

soda and citric acid, etc.

2. Abrasive material and ceramic industry: alumina, quartz, welding

rod powder, aluminum, alloy powder, etc.

3. Metallurgy and mining: Titanium oxide, zinc oxide,

electromagnetism materials, metal materials, welding rod materials,

etc.

4. Paper-Making Industries: coated slurry, exhaust liquid, paper

making liquid, waste water reclamation, etc.

5. Food industry: wheat flour,sugar, salt, alkali, milk powder,

soybean milk, yeast, juice, soy sauce, vinegar, etc.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com