Xinxiang AAREAL Machine Co.,Ltd |

|

Graphite Grains Tumbler Screening Machinee Large Output Carbon Steel Material

Overview of Tumbler Sieve Screening Machine for Amorphous Graphite Grains:

Tumbler sieve screening machine for amorphous graphite grains is efficient and specifically designed to meet the large output, low-density sieving and processing of fine powder and special materials. The tumbler sieve is also called tumbler screening machine, tumbler screen, tumbler screener, swinging screen, swinging sieve, rocking sieve, shaking sieve machine etc.

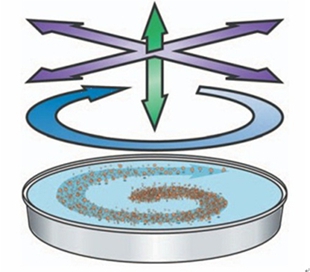

Unlike the typical vibratory or gyratory screening machine, the tumbler screening machine incorporates a unique three-dimensional tumbling motion providing the gentlest screening possible. This motion prevents delicate, friable material from being broken resulting in less undesirable fine generation and dust levels. Even the most difficult materials, which tend to blind screens, are screened efficiently by utilizing the proper anti-blinding systems including motor driven brushes and/or air knives that are unique to tumbler type screening machines.

Tumbler screen machines are used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes. Our AM model tumbler screen machine features a range of customization options designed to meet extremely demanding requirements, as well as a broad variety of additional equipment options. Among these, the number of available screen cleaning systems is particularly worth mentioning, with balls, brushes, ultrasonic, and various combinations being of these options are available to prevent blinding and maintain efficient screening.

Features of Tumbler Sieve Screening Machine for Amorphous Graphite Grains:

Our Advantages:

1. 30 years of production experience, reliable quality and service.

2. Entire modern production line, all sieving machines can be

customized.

3. Design and create professional integrated sieving solutions for

clients.

4. ISO certificated.

5. Reasonable cost and fast delivery.

6. Provide video inspection of goods, video installation guidance.

7. Online technical support.

8. 12 months quality guarantee and lifetime technical assistance.

Working Principle of Tumbler Sieve Screening Machine for Amorphous Graphite Grains:

The tumbler screener utilizes the humanoid screening principle. To imitate the movement of artificial screening action and do three-dimensional circular motion, skillfully combine the sieving (planar circular motion) and winnowing (upward parabolic motion), establish horizontal and throwing three-dimensional tumbling movement, make the material in the screen surface appear involute spiral movement. The material takes a relatively long distance across the relative area, and the landing screen time of the material is more than 85%, improving the screen through rate. The screening accuracy is as high as 90%~99%, increasing the yield.

1. Basic rotary motion is similar to hand screening. The

eccentricity is adjustable from 25 to 40mm, low-speed V-belt drive

is adjustable from 120 to 360rpm.

2. Each product’s dwell time can be adjusted in a radial and

tangential angle, towards the drive axis.

3. Therefore, establishing the horizontal and throwing

three-dimensional rolling movement, materials are evenly dispersed

on the entire sieve surface from the center to the outer edge, and

thus spread towards the axis by spiral movement. Small particles

are then finished in the whole sieving process.

4. The horizontal and vertical acceleration are increased with the

movement of the particles, and then the particles which are close

to mesh size will be successfully separated; the larger particles

are transported to the exit, the flow can be controlled by a

regulated oriented device at the exit, the oriented device is

another factor which controls the dwell time of the materials.

5. The process is repeated in each layer.

Important Information About Tumbler Sieve Screening Machine for Amorphous Graphite Grains You May Care:

| Motion | involute spiral motion |

| Screening Accuracy | upto 90%~99.9% |

| Mesh Cleaning Method | bouncing ball cleaning, ultrasonic cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen |

| Diameter | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm, 2900mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | quick clamps, pneumatic lifting devices etc. |

| Application | can be used for material that is flammable, explosive and easy to generate static |

| Motor Brand | Siemens, ABB, BEGEMA etc. |

Application of Tumbler Sieve Screening Machine for Amorphous Graphite Grains:

Tumbler screen machine is widely used in spices, tea, sugar, salt, renewable resources, plastics, rubber, EPS, PVI, PVC, resin and other industries for fine material screening.

1. Chemical industry: resin, pigment, industrial medicine, cosmetic, coatings, Chinese

medicine power etc.

2. Food industry: sugar powder, starch, salt, rice noodles, milk powder, soybean

milk, egg powder, sauce, syrup etc.

3. Metal, metallurgy mining industry: aluminum powder, ceruse, copper powder, ore alloy powder, welding

rod powder, dioxide manganese, electrolyse copper powder, lithium

battery materials, rubbing powder, fire-proof material, kaolin,

lime, alumina, heavy calcium carbonate, quartz. Social pollution

disposed; disposed oil, disposed water, disposed dye waste water,

assistant detergent, active carbon etc.

Technical Parameters of Tumbler Sieve Screening Machine for Amorphous Graphite Grains:

| Model | Screen Area (m²) | Layers of Screen | Motor Power (KW) |

| AM-600 | 0.28 | 1~5 | 0.25 |

| AM-1000 | 0.72 | 1~5 | 1.5 |

| AM-1200 | 1.10 | 1~5 | 1.5 |

| AM-1500 | 1.80 | 1~5 | 2.2 |

| AM-1800 | 2.30 | 1~5 | 4.0 |

| AM-2000 | 2.60 | 1~5 | 4.0 |

| AM-2300 | 3.90 | 1~5 | 4.0 |

| AM-2600 | 5.30 | 1~5 | 5.5 |

| AM-2900 | 6.40 | 1~5 | 5.5 |

BALANCE IS IMPORTANT !! Pneumatic Lifting Device

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com