Xinxiang AAREAL Machine Co.,Ltd |

|

Magnesium Hydroxide Tumbler Screening Machine Large Screening Capacity

Introduction of Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity is a high powered sieving machine used by manufacturers from different industries to produce large outputs of light powder particles with high capacity by continuous low-density sieving.

Characteristics of Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

1. Ingenuity: Circular building block assembly structure, small

volume, light weight. Easy to install and disassemble.

2. Can add many kinds of the self-cleaning device to the screen

surface. Can avoid blocking the screen. There are five kind of

self-cleaning device for you to choice: bouncing ball, Rolls

brushes, jet type, elastic scraper, ultrasonic.

3. No environment pollution: Fully closed structure, almost no let out of material dust.

4. High screening accuracy: It can imitate the screening action and process of manual operation effectively. Make the material walk a long distance on the screen surface, improve the screening accuracy.

5. High capacity: The unit area capacity is five times bigger than

other screen.

6. Long service life: Low frequency, small load, so low load to the

screen, can be used for long time.

7. Use brand motor as power source:with longer service life.

8. Low noise: The noise < 75db

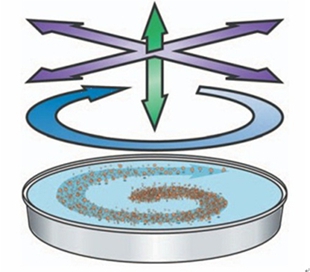

Working Principle of Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

The tumbler screener machine is drived by a unbalance motor, which is with variable eccentric weights on both sides of motor shaft. The screening time and movement of material on the screen surface can be controlled by adjusting the angle of the two eccentric weights.

Technical Parameters of Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

| Model | Screen Area (m²) | Layers of Screen | Motor Power (KW) |

| AM-600 | 0.28 | 1~5 | 0.25 |

| AM-1000 | 0.72 | 1~5 | 1.5 |

| AM-1200 | 1.10 | 1~5 | 1.5 |

| AM-1500 | 1.80 | 1~5 | 2.2 |

| AM-1800 | 2.30 | 1~5 | 4.0 |

| AM-2000 | 2.60 | 1~5 | 4.0 |

| AM-2300 | 3.90 | 1~5 | 4.0 |

| AM-2600 | 5.30 | 1~5 | 5.5 |

| AM-2900 | 6.40 | 1~5 | 5.5 |

BALANCE IS IMPORTANT !! Pneumatic Lifting Device

Application of Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

The tumbler screening machine is widely used in a variety of industries. For example, it can be used to remove Impurities in food processing to ensure product quality and safety. For the chemical industry, solids can be separated from solids or liquids. In addition, it can also be used in medicine and recycle , Mining, plastic, soil, etc. to classify light, heavy, small, dry, dusty, wet and sticky materials of various particle sizes.

1. Metallurgy, Mine industry: aluminum powered, copper powder, ore

alloy powder, welding rod powder.

2. Waste treatment: disposed oil, disposed water, disposed dye

waste water, active carbon.

3. Medicinal industry: all kinds of medicine.

4. Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powder.

5. Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce.

Important Information About Tumbler Screening Machines for Magnesium Hydroxide with Large Screening Capacity:

| Motion | involute spiral motion, imitate the manual screening action |

| Screening Accuracy | upto 90%~99.9% |

| Diameter | 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1600mm, 1800mm, 2000mm, 2300mm, 2600mm etc. |

| Mesh Cleaning Method | bouncing ball cleaning, ultrasonic de-blinding system, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen |

| Diameter | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm, 2900mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | quick clamps, pneumatic lifting devices etc. |

| Application | can be widely used for material that is flammable, explosive and easy to generate static |

| Motor Brand | ABB, Siemens, BEGEMA etc. |

| Surface Treatment | polishing, sandblast, paint spraying etc. |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com