Xinxiang AAREAL Machine Co.,Ltd |

|

Chemical Industry Linear Vibrating Screen Double Horizontal Vibrating Motors

Introduction of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

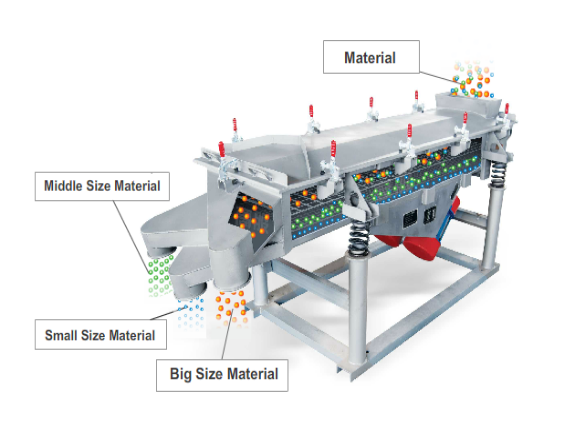

Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry is a classical and universal fine screening equipment. The movement track of its screen box is close to straight line. Almost all the linear vibrating screens are consisted of the screen box, supporting or hanging device, driving unit, vibration isolation part etc.

Working Principle of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

The linear vibrating sifter machine uses double vibrating motors to drive, when two motors rotate synchronously and reversely, exciting forces generated by eccentric block are resolved in parallel to the direction of motor axis and then united as one across the motor axis direction,so its movement track is linear. There is an angle of inclination between the two motor axises relative to the screen deck. Under the influence of the resultant force of exciting force and materiels itself weight,materiels are thrown up to make leapfrog and linear movement forward on the screen deck in order to screen and grade the materiel .Applied in flowing line to achieve automatical operation.

Important Information About Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

| Model | AZ-515, 520, 525, 1025, 1030, 1040, 1225, 1230, 1235, 1535 etc. |

| Shape | rectangular shape |

| Motion | linear motion |

| Structural Composition | screen box, screen, vibration motor, motor base, damping spring, support etc. |

| Vibrating Motor | two sets of horizontal vibrating motors, synchronous reverse rotation |

| Applicable Material | suitable for sieving 0.074mm~10mm non-sticky materials with moisture content less than 7% |

| Screen Surface | horizontal or inclined (0°~7°) |

| Layers of Screen | 1~6 layers of screen (The higher layers can be customized according to the actual situation) |

| Screen Frame | wooden screen frame, carbon steel screen frame, stainless steel screen frame etc. |

| Mesh Cleaning Method | bouncing balls, ultrasonic system etc. |

| Material | carbon steel, stainless steel 304/316L, titanium material etc. |

| Screen Size | screen width*length 500*2000mm, 500*2500mm, 1000*2000mm, 1000*2500mm, 1000*3000mm, 1000*4000mm, 1200*2500mm, 1200*3500mm, 1200*4000mm, 1500*3500mm etc. |

| Application | plastic particle, tea, chemical fertilizer, lysine, urea, organic fertilizer, limestone, fodder, feeding stuff, refractory material etc. |

| Surface Treatment | Sand blasting, plastic spraying, spray paint, mirror polishing etc. |

Application of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

1. Chemical industry: grease, paint, palette, resin pigment,

medicine, etc.

2. Plastics industry.

3. Abrasive material and ceramic industry: abrasive, refractory

material, building sand, mica, alumina, slurry, etc.

4. Food industry: starch, milk powder, yeast powder, sugar, salt,

alkali, gourmet powder, pollen, food additive, bean milk, juice,

etc.

5. Organic fertilizer industry.

6. Mechanical industry: powder metallurgy, casting sand,

electromagnetic material and metal powder, etc

7. Metallurgy and mining industry: quartz sand, ore, titanium

oxide, zinc oxide, etc.

8. Paper-making industry: coated slurry, exhaust liquid, paper

making liquid and waste water reclamation, etc.

Structural Composition of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

The rectangular vibrating screens are composed of screen box, vibration motor, damping system and chassis. The screen box consists of chute, roof, screen frame, screen plate (mesh), wire gauze.

1. Screen box: welded by steel plate, with certain strength and rigidity, it is

the main component of screen machine.

2. Screen Mesh: the screen mesh is perforated plate. The overall stiffness is

good, solid and reliable.

3. Vibration motor: the vibration motor use and maintenance method to see the vibration motor operating instructions.

4. Vibration damping spring: to prevent vibration from passing to the ground and support the full weight of the screen box. When installing, the spring must be perpendicular to the ground.

5. Motor pedestal: the motor pedestal of the down vibration type of sieve machine

(the motor is installed under the sieve box) can be moved. The

connecting screw must be tightened before using, Especially the new

screening machine must be repeatedly tightened three days before

trial, so as to avoid accidents caused by loosening.

6. Bracket: the bracket is used to support the screen box. It must be mounted

perpendicular to the ground during installation. The bracket and

sieve body part shall be joined by the compression spring.

Features of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

1. High accuracy in screening, high yield and simple structure.

2. The weld joints of each part of the sieve body adopt rolled

plate and proximate matter (part of the group adopt bolted

connection), it has such characteristics as good integral rigidity

and fastness and reliability.

3. Totally closed structure, automatic discharging, more suitable

for assembly line work.

4. Less energy consumption, low noise, long service life of the

screen.

Technical Parameters of Large Capacity Linear Vibratory Screener Machine Used In Chemical Industry:

| Model | Nominal Size (mm) | Particle Size (mm) | Leaning Angle of Screen (°) | Amplitude (mm) | Layer | Power (Kw) |

| AZ-520 | 500*2000 | 0.074~10 | 0~7° | 4~10 | 1~6 | 2*(0.4~0.75) |

| AZ-525 | 500*2500 | 2*(0.4~0.75) | ||||

| AZ-530 | 500*3000 | 2*(0.4~0.75) | ||||

| AZ-1020 | 1000*2000 | 2*(0.4~0.75) | ||||

| AZ-1025 | 1000*2500 | 2*(0.4~1.1) | ||||

| AZ-1030 | 1000*3000 | 2*(1.1~1.5) | ||||

| AZ-1040 | 1000*4000 | 2*(1.1~1.5) | ||||

| AZ-1225 | 1200*2500 | 2*(1.1~1.5) | ||||

| AZ-1235 | 1200*3500 | 2*(1.1~2.2) | ||||

| AZ-1250 | 1200*5000 | 2*(1.1~2.2) | ||||

| AZ-1535 | 1500*3500 | 2*(1.1~2.2) | ||||

| AZ-1560 | 1500*6000 | 2*(2.2~3.7) | ||||

| AZ-1845 | 1800*4500 | 0.074~15 | 2*(2.2~3.7) | |||

| AZ-2050 | 2000*5000 | 2*(2.2~3.7) | ||||

| AZ-2060 | 2000*6000 | 2*(2.2~3.7) |

Note: The data in the table are for reference only. Our company reserve the right to modify the above data.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com