Xinxiang AAREAL Machine Co.,Ltd |

|

Ammonium Nitrate Linear Vibrating Screener Rectangular Sifter Low Noise

Introduction of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

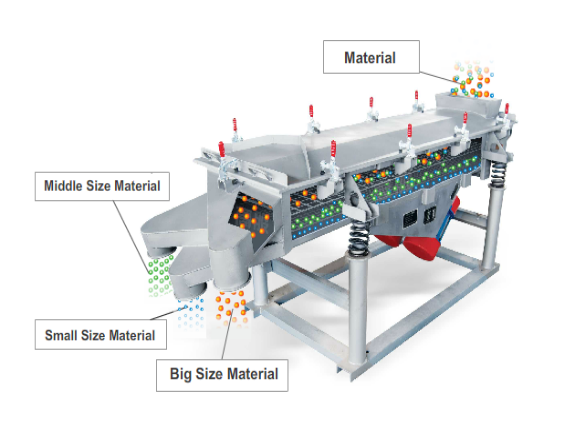

The Classic Efficient Linear Vibrating Screener for Ammonium Nitrate is a kind of closed and light weight linear vibrating sifting equipment that is commonly used, it uses a vibration motor as the vibration source, which make the material jump in straight line on the screen of the sifter, material evenly go into the feed port of the linear vibrating screen from the feeding machine, generate multi-standard materials through the multilayer screen and be discharged from each discharge hole.

The linear vibrating screen can also be called rectangular separator, linear vibrating screen, linear vibrating sieve, inclined vibrating screen, horizonal vibrating screen, rectangular vibrating screen, rectangular sifter, rectangular screener, linear screen etc.

Working Principle of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

The linear vibrating screens use two vibrating motorsas the power source. The eccentric blocks driven by the motors could provide centrifugal force, whose component force moves forward along the linear direction. Thus the screen device supported by the spring suspension can move linearly. And the material on it moves forward straightly when tossed upward. When falls into the screen frame again, the material will move forward quickly and penetrate the screen in a fluffy state. Desirable screening performance can be achieved simply by choosing suitable screens for the linear vibrating screen.

Important Information About Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

| Other Names | linear vibrating sieve, rectangular separator, inclined vibrating screen, horizonal vibrating screen, rectangular vibrating screen, rectangular sifter, rectangular screener, linear screen etc. |

| Shape | rectangular shape |

| Motion | linear motion |

| Structural Composition | screen box, screen, vibration motor, motor base, damping spring, support etc. |

| Vibrating Motor | two sets of horizontal vibrating motors, synchronous reverse rotation |

| Applicable Material | suitable for sieving 0.074mm~10mm non-sticky materials with moisture content less than 7% |

| Screen Surface | horizontal or inclined (0°~7°) |

| Layers of Screen | 1~6 layers of screen (The more layers can be customized according to the actual situation) |

| Screen Frame | wooden screen frame, carbon steel screen frame, stainless steel screen frame etc. |

| Mesh Deblinding System | bouncing balls, ultrasonic system etc. |

| Material | carbon steel, stainless steel 304/316L, titanium material etc. |

| Screen Size | screen width*length 500*2000mm, 500*2500mm, 1000*2000mm, 1000*2500mm, 1000*3000mm, 1000*4000mm, 1200*2500mm, 1200*3500mm, 1200*4000mm, 1500*3500mm etc. |

| Application | plastic particle, tea, chemical fertilizer, lysine, urea, organic fertilizer, limestone, fodder, feeding stuff, refractory material etc. |

Structure of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

The linear vibrating screen is composed of two vibration motors, a sieve box, a screen mesh, a vibration absorbing body and a vibration damping device etc.

1. Sieve box: welded by steel plate, with certain strength and rigidity, it is

the main component of screen machine.

2. Screen Mesh: the screen mesh is perforated plate. The overall stiffness is

good, solid and reliable.

3. Vibration motor: the vibration motor use and maintenance method to see the vibration motor operating instructions.

4. Motor pedestal: the motor pedestal of the down vibration type of sieve machine

(the motor is installed under the sieve box) can be moved. The

connecting screw must be tightened before using, especially the new

screening machine must be repeatedly tightened three days before

trial, so as to avoid accidents caused by loosening.

5. Vibration damping spring: to prevent vibration from passing to the ground and support the

full weight of the screen box. When installing, the spring must be

perpendicular to the ground.

6. Bracket: the bracket is used to support the screen box. It must be mounted

perpendicular to the ground during installation. The bracket and

sieve body part shall be joined by the compression spring.

Characteristics of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

1. Easy operating:

Benefited by its simple structure, the operating also become very easy and convenient. The operator just need to fixed it well and connect with the suitable power. During the running, please make sure no hard matter touch it, and regularly check if any parts is loose.

2. Large capacity:

Material screening have been subdivided to several kinds. Compared with probability screening, the linear vibrating screen could be installed the fine screen cloth, so it could be used in crusher or milling production line to work for fine screening. Compared with rotary vibrating screen, it has a greater capacity. The linear vibrating screen makes up the greater capacity requirement in fine screening field.

3. Low maintenance cost:

Benefited from its simple design, besides the screen cloth, there is very few wearing parts on the machine. It does not need a high maintenance cost. It is also very helpful to reduce downtime and improve the productivity.

4. Equably feeding system:

In order to make sure equable feeding, a feeding distributor is added at the inlet, which can help to distribute the material on the screen cloth. This device could reduce the rate of jamming or pegging to increase the efficiency of screening and passing. And it can also prevent the screen cloth from being damaged by too much material accumulation. User could freely control the feeding rate based on their requirement.

5. Multifunction:

Besides the screening, the linear vibration motion could equably loose material to feed the downstream equipment during running. So the linear vibrating screen could be also used as a vibrating conveyor or feeder while screening.

6. Low working noise:

Its bounce balls structure is without perforated steel. So there is no knocking noise in the processing of working. Its working noise is controlled at a lower level. In the long term, the operator do not need to bear the working noise, which safeguard staff’s healthy.

7. Customize service:

The machine dimension, variable voltage, mobile wheel and other non-standard design could be customized according to user’s requirements. ODM and OEM are also available.

Application of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

The rectangular vibrating is mainly used in powder, granular materials selection and classification, widely used in plastics, abrasives, chemicals, pharmaceuticals, building materials, food, carbon, fertilizer and other industries.

Technical Parameters of Classic Efficient Linear Vibrating Screener for Ammonium Nitrate:

| Model | Nominal Size (mm) | Particle Size (mm) | Leaning Angle of Screen (°) | Amplitude (mm) | Layer | Power (Kw) |

| AZ-520 | 500*2000 | 0.074~10 | 0~7° | 4~10 | 1~6 | 2*(0.4~0.75) |

| AZ-525 | 500*2500 | 2*(0.4~0.75) | ||||

| AZ-530 | 500*3000 | 2*(0.4~0.75) | ||||

| AZ-1020 | 1000*2000 | 2*(0.4~0.75) | ||||

| AZ-1025 | 1000*2500 | 2*(0.4~1.1) | ||||

| AZ-1030 | 1000*3000 | 2*(1.1~1.5) | ||||

| AZ-1040 | 1000*4000 | 2*(1.1~1.5) | ||||

| AZ-1225 | 1200*2500 | 2*(1.1~1.5) | ||||

| AZ-1235 | 1200*3500 | 2*(1.1~2.2) | ||||

| AZ-1250 | 1200*5000 | 2*(1.1~2.2) | ||||

| AZ-1535 | 1500*3500 | 2*(1.1~2.2) | ||||

| AZ-1560 | 1500*6000 | 2*(2.2~3.7) | ||||

| AZ-1845 | 1800*4500 | 0.074~15 | 2*(2.2~3.7) | |||

| AZ-2050 | 2000*5000 | 2*(2.2~3.7) | ||||

| AZ-2060 | 2000*6000 | 2*(2.2~3.7) |

Note: The data in the table are for reference only. Our company reserve the right to modify the above data.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com