Changzhou Welldone Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

(1)Different feeding devices are available for different materials to make sure the feeding process smooth and stable.

(2)The water cooling system is equipped at the bottom of drying chamber to protect the material from deterioration under high temperature condition.

(3)The special pneumatic seal device and cooling device can considerably extend the service life of the shaft and driven system.

(4)The special air disperser can considerably increase the swirl air flow.

(5)The drying chamber is equipped with classification ring and whirl plates which can respectively control the size and moisture of the final products.

(6)The high speed of the swirl air flow inside the drying chamber can considerably reduce the drying time and protect the thermal sensitive material from sticking to the inner wall and deterioration. It is compact and high efficiency.

(7)The blower at the bottom of the drying chamber can generates strong air flow at the speed of 50-60m/s to protect the particle from entering into the hot air pipeline.

(8)The disintegrator is cooled by water jacket to protect the material from sticking to the inner wall because of high temperature.

The heart of the process is the drying chamber where the feed disintegration and evaporation take place. The hot air with suitable spray speed is introduced into the drying chamber through air disperser at the bottom of the drying chamber which generates swirl air flow. Meanwhile the material will be feed into the drying chamber and drop onto the high speed rotating disintegrator, a series of rotating blades that impact the material, and cut into small particles. With the impact of swirl air flow and rotating disintegrator, the swirl air flow conveys the particles and moves to the top of the drying chamber. During the mixing and heat transfer between the hot air and particle products, the moisture will be evaporated in seconds. For those big lumps which are not easy to dry will be dropped onto the disintegrator and re-grinded for drying. The dried particles and spent drying gas exit the drying chamber through the outlet at the top of the chamber. The outlet is connected with cyclone and bag filter for dust removing process. The products will be collected at the bottom of the cyclone and the waste gas will be exhausted into the air after been filtered by bag filter.

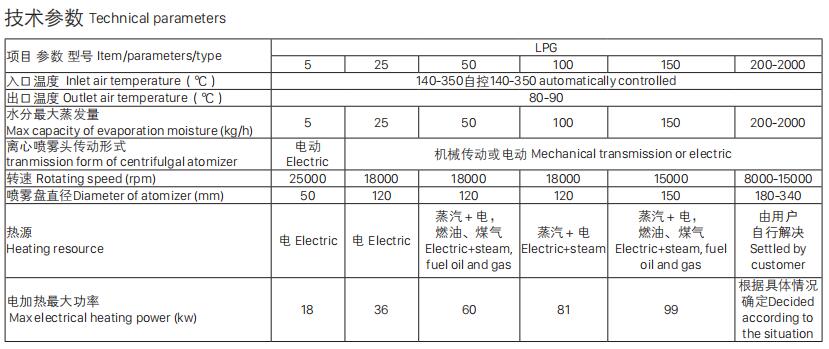

Technical Parameters of High Efficient GMP Standard Titanium Dioxide Spin Flash Dryer/ Drying Machine

Picture of High Efficient GMP Standard Titanium Dioxide Spin Flash Dryer/ Drying Machine