Changzhou Welldone Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

KJG double paddle dryer is a kind of contacting dryer. There is jacket on the body of dryer, hollow paddle strongly welded on two hollow shafts, filling heating medium (could be hot water, steam or thermal oil) in them, wet raw material is heated, dried as well as driven forward by two shafts.

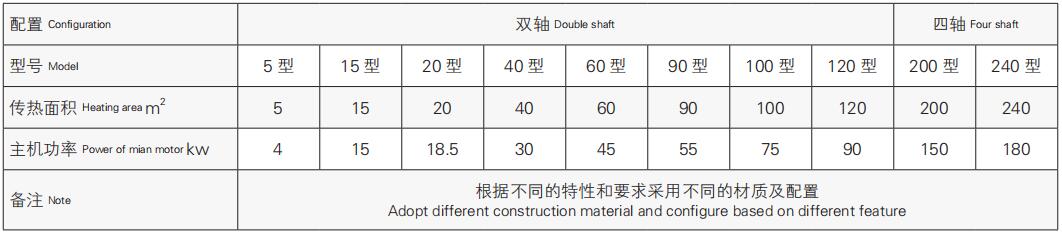

It could be consisted of one to four shafts, whole operation will be finished in closed or partial closed environment.

--1 Drying efficiency could arrives 80%-90%. Heat transfer

coefficient K is 100-300Kcai/h.m2℃. Evaporation capacity is

10-30Kcai/h.m2.

--2 The dryer support continuous operation and batch operation,

support vacuum drying for thermal sensitive material and normal

drying. Support heating, evaporating and cooling.

--3 Thermal oil, steam, hot water and chilling fluid are available

to be used as heating/cooling medium

--4 Special structure of paddle which has large heating area.

--5 Structure of dryer is very compact, almost of the dryer could

be transported by normal container.

Picture of Double Shaft Paddle Dryer in Working