Changzhou Welldone Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

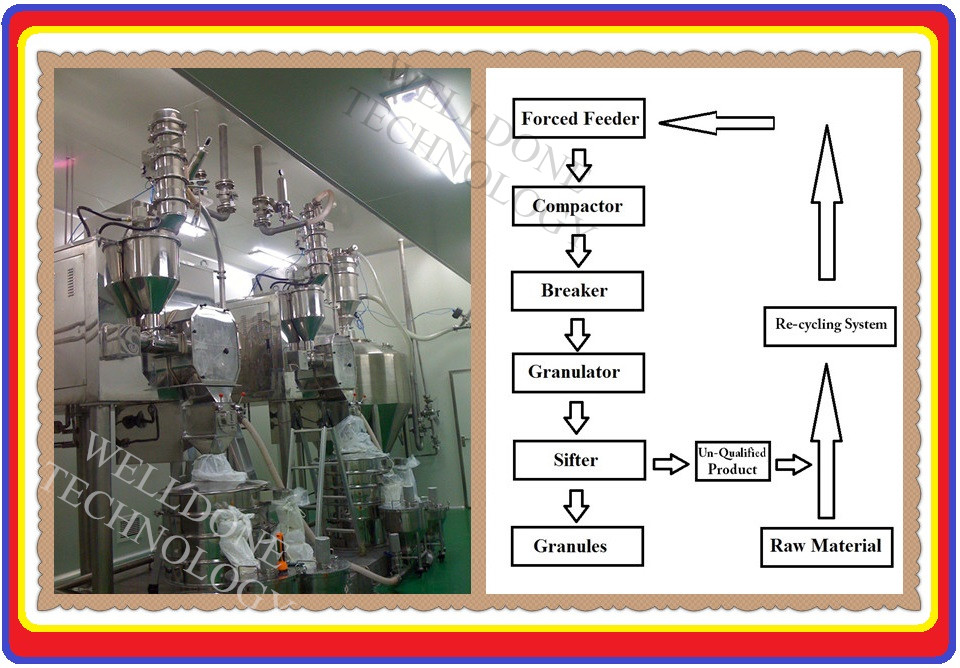

GMP dry granulator is developed with combination of Germany technique. Compared against conventional dry granulator, GMP has much better granulation rate, and it is easier for a thorough cleaning. It is specially designed for pharmaceutical and food industry, which could meet GMP standard.

(1) Vertical feeding instead of conventional horizontal feeding.

(2) Screw feeder feeding the raw material into rollers.

(3) Roller are cantilever installed, which is easy for dissemble

and clean.

(4) Vertical layout of two rollers, could avoid raw material

dropping because of gravity.

(5) Two level of sifting system could increases granulation rate

(6) The granulator works in closed operation, which avoids dust

pollution.

(7) PLC and touch screen as an optional choice

The equipment is suitable in pharmaceutical industry, food Indurtsy, chemical industry, soda ash, fertilizer, feed, plastic additive, cosmetic, synthetic detergent and so on.

Picture of Dry Granulator in Working