Dongguan Osmanuv Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

1.5KW 15m/Min Varnish Spot Uv Printing Machine Coating Production

Science and technology continue to advance, and new technologies, new materials, and new processes continue to emerge. The development of electronic technology, numerical control technology, laser technology, microwave technology and high-voltage electrostatic technology has brought new vitality to the automation, flexibility, intelligence and integration of coating equipment, which has led to the continuous increase of the variety of machine tools and the continuous improvement of the technical level.

Description:

| 1 | Product name: Back paint machine. |

| 2 | Model: OSM-BQ-1320 type. |

| 3 | Features: It is suitable for all kinds of wood, plastic, metal and other flat coatings. The surface of the paint processed by this machine is smooth, full and no color difference. |

| 4 | Mechanical dimensions: 1000mm long × 2300mm wide × 1520mm high. (According to actual size) |

| 5 | Effective working size: a, effective width: 1320mm; b, thickness: 3-80mmc, length (shortest): 300mm. |

| 6 | Material: The shell is made of 1.5mm steel plate by bending and welding, the surface is treated with liquid paint, and the supporting wall is made of 20cm steel plate (A3 material). |

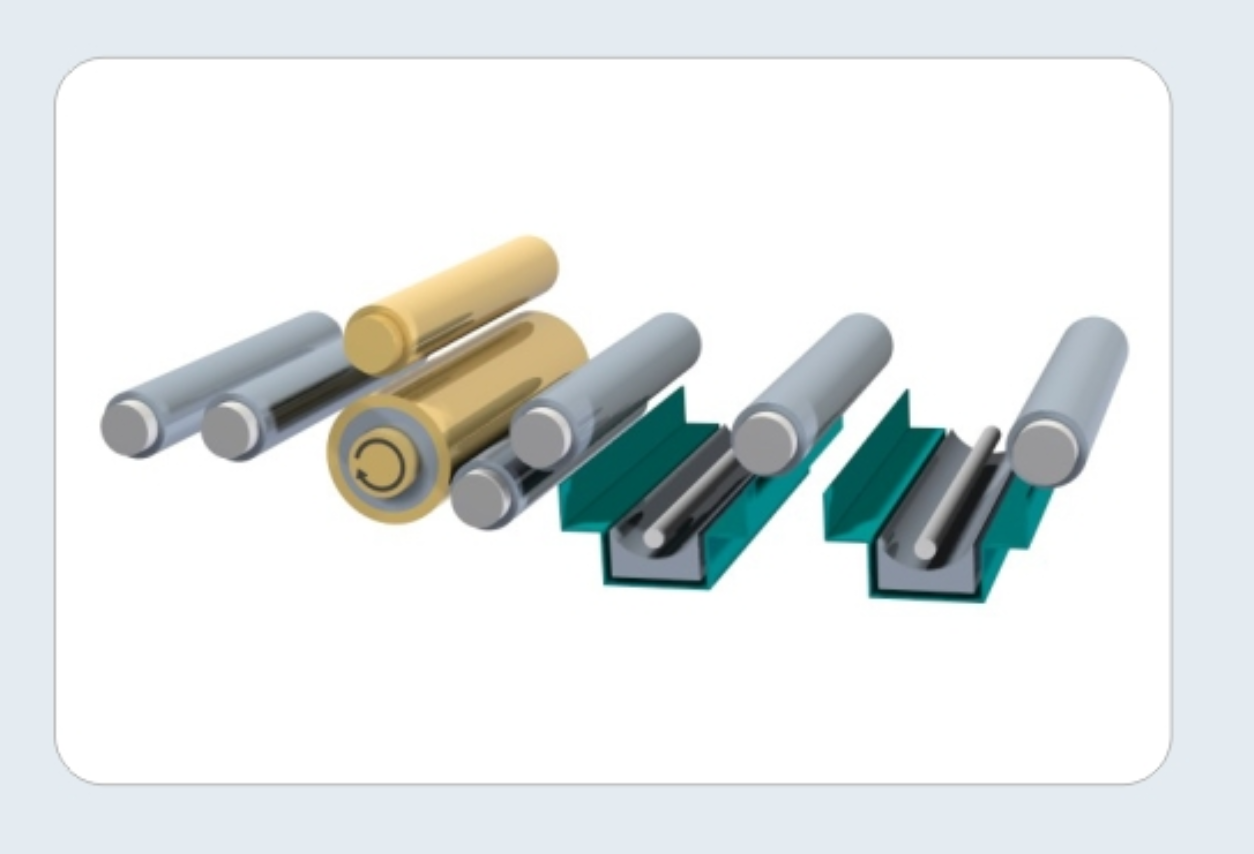

| 7 | Coating part: A single-group roll coating system is adopted. Each group of systems consists of steel rollers and silicone wheels. Each group of roll coating systems can be lifted and lowered individually. |

| 8 | Coating roller: Diameter: ¢205mm, length: 1420mm, made of high-quality Japanese silicone, wear-resistant, good elasticity, hardness can be customized according to customer requirements (40-50 degrees), and can withstand various solvents. .Adopt high-quality coupling for transmission, bearing adopts NSK bearing, Delta frequency converter controls the speed of rubber roller, |

| 9 | Measuring wheel: Diameter: ¢130 mm, length: 1420mm, using 45# seamless steel pipe welded by CO², the surface is finely ground, dynamic balance, runout is less than 0.05mm, the surface is electroplated hard chrome and polished to achieve a bright effect. The direct plug-in connection transmission can truly be integrated with the drive motor. |

| 10 | Conveying roller: power: 1.5KW, diameter: ¢130 mm, length: 1320mm. The 45# seamless steel pipe is welded by CO². The surface is finely ground and dynamically balanced. The runout is less than 0.05mm. The surface is hard chrome electroplated and polished to achieve a bright effect. Direct plug-in connection transmission can truly be integrated with the drive motor. |

| 11 | Conveyor belt: adopts roller drive, stable conveying and long service life. |

| 12 | Conveying speed: 1-15m/min. |

| 13 | Working height: 850~900mm (the height of the belt from the ground), the height of the roller is equipped with a position indicator. |

| 14 | Control system: 3 sets of Siemens machines and 3 sets of Delta frequency converters are adopted, and each roller can be adjusted independently. |

| 15 | Electrical appliances: use Delta inverters, CHNT contactors, Siemens motors, Japanese Izumi switches and other famous-brand electrical appliances that meet international safety standards. |

| 16 | Safety device: This machine has leakage circuit breaker, motor overload protection, abnormal emergency switch, control circuit fuse, etc. in line with international safety standards. |

FAQ

Q: Are you trading company or manufacturer?

A: We are a manufacturer owns foreign trade independent import and

export rights. Our factory is located in Guangdong, China.

Q: How can I know your machine has good quality?

A: Firstly, we will have your samples for a trial on our machines,

and make a video for you to watch the testing, factory visit is

also available. Moreover, our products are widely used in China,

Southeast Asia, South America, and Europe.

Q: What certifications do you have?

A: Fully in accordance with the GMP & ISO standard production

and our products have passed CE certification for exporting.

Q: What is your Quality Warranty?

A: One year warranty; Lifelong Maintenance and Technical Support.