Xiangjing (Shanghai) M&E Technology Co., Ltd |

|

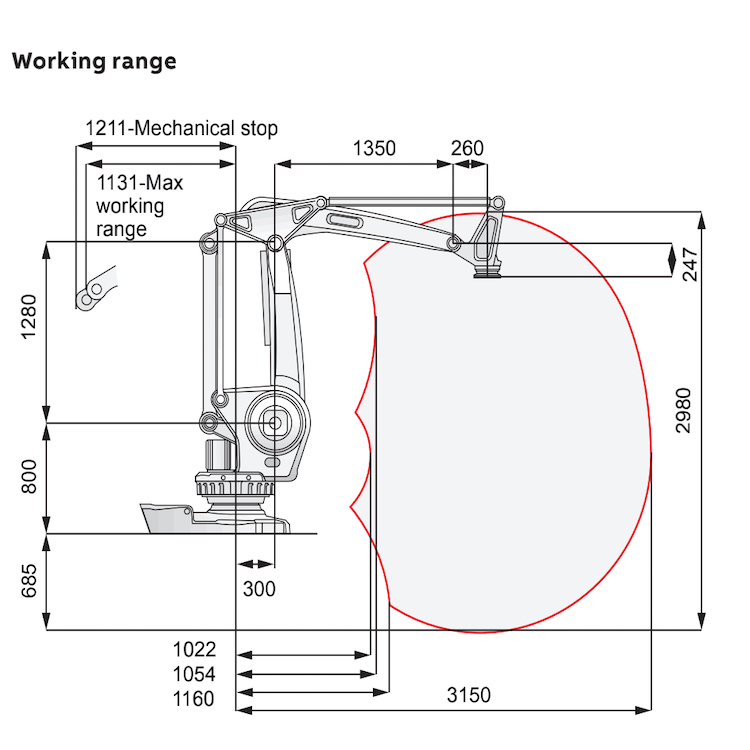

Used ABB IRB 660 Paper Roll Fork Lift With Manipulator with Max Reach 3150mm Light Palletizing Robot Arm Taking palletizing to new heights

Specification

Robot version | Reach (m) | Handling capacity (kg) | Cycles per hour |

IRB 660-180/3.15 | 3.15 | 180 | 1570 |

IRB 660-250/3.15 | 3.15 | 250 | 1360 |

Position repeatability | Path repeatability | |

| IRB 660-180/3.15 | 0.1mm | 0.3mm |

| IRB 660-250/3.15 | 0.1mm | 0.3mm |

More products:

KUKA robot

1: KR 6 R1820 6KG 6axis welding robot

2: KR 6 R700 sixx 6 axis payload 6kg multifunctional industrial robot

3: KR 10 R1420 6 aixs 10kg welding robot

4: KR 210 R2700 EXTRA 210KG payload multifunctional industrial robot

ABB robot

1: IRB 1200/7/0.7 6 axis 7kg payload multifunctional industrial robot

2: IRB 1520ID 6 axis 5kg payload for welding

3: IRB 6700/150/3.2 150 kg payload for handing,cutting and palletizing

Collaborative robot

1: Collaborative robot of Chinese industrial robot arm 6 axis 6kg paylad

2: Collaborative robot of chinese industrial robot arm 7 axis 5kg payload

Xiangjing (Shanghai) Electromechanical Technology Co., Ltd., founded in 2015, is a supplier of automation, intelligent control technology, products and solutions controlled by Dr. Industrial Group. The business field involves many fields, such as automation system, industrial process control and intelligent manufacturing. For energy, petrochemical, electric power (including nuclear power), iron and steel, automobile, building materials and other process industries, Xiangjing already has a series of industrial automation products from on-site monitoring instruments, automatic control valves to automatic control systems, advanced control and optimization, production execution system, energy management system and other industrial software and intelligent manufacturing overall solutions, constitute a complete process industrial intelligent factory solution, has formed a series of large and medium-sized customers such as China Nuclear, Shanghai Airport, Shanghai Electric, Shanghai Automobile, Baosteel, Jiangnan Shipyard, Huisheng Engineering, Datang Electric Power, etc. We have been committed to the integration of information and industrialization to help industrial enterprise users move towards industry 4.0. In the new round of digital wave and industrial transformation, we will use industrial big data, industrial Internet and intelligent technology to excavate and create new value in order to realize the integration and innovation of process technology equipment technology, operation technology, automation technology information technology, enable users to achieve the goal of "safety, quality, cost reduction, efficiency, environmental protection ", and help the green, digital and intelligent development of the whole social industry to make work and life easier.

1.Swift delivery

For common parts, we can deliver the goods within 3 days

2.Original products

All the products we sell are from origin manufacturer. We will submit all the manufacturer documentation while we finish delivery.

3.Quality Assurance

4.Technical Support

Including inspection,repair and maintenance, we can give all kinds of technical support.

5.Quickly responce

Our staffs will keep 24h online and answer your question very quickly.