Beijing Silk Road Enterprise Management Services Co.,LTD |

|

Verified Suppliers

|

|

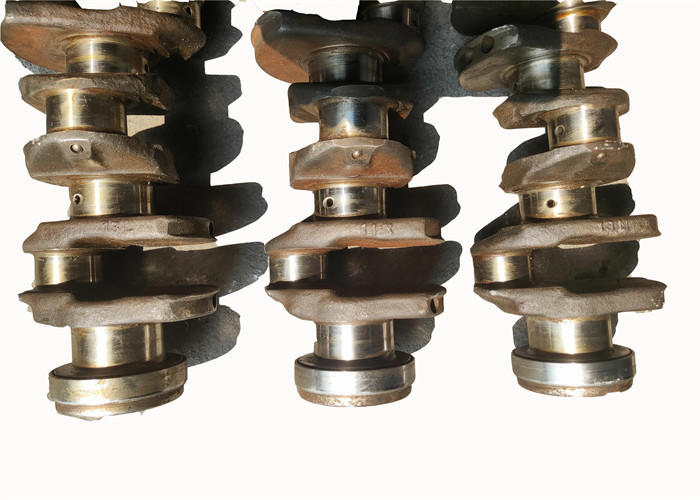

D1105 D1005 Second Hand Crankshaft For Excavator KX175 KX183 - 3 1G065 - 23010

Specification

| Product name: Engine crankshaft | Model Number: D1105 D1005 | |

| Application: Excavator | Part number: 1G06523010 | |

| Part code: 16265-23013 | valve: 6 valve | |

| Weight: 14kg | Number of Cylinders: 3 | |

| Cooling: Water cooling | Injection: Eddy Injection | |

Description

Parts of Crankshaft

Following are the main parts of crankshaft with its diagram:

1.Crankpin

2.Main journals

3.Crank web

4.Counterweights

5.Thrust washers

6.Oil passage and oil seals

7.Flywheel mounting flange

1. Crank Pin

The crankpin is a mechanical part of an engine. Which allows the

connecting rod to be attached to the crankshaft very firmly.

The surface of the crankpin is cylindrical, to give the rotative force to the large end of the connecting rod. These are also known as connecting rod journals.

2. Main Journals

Journals have attached to the engine block. These bearings hold the

crankshaft and provide it to rotate inside the engine block. This

bearing is such as a plain bearing or journal bearings. The main

bearings vary from engine to engine, often according to the forces

given by the engine.

3. Crank Web

The Crank web is the most essential part of the crankshaft. Crank

web connects the crankshaft to the main bearing journals.

4. Counterweights

The counterweights are a type of weight, that applies opposite

force, which provides balance and stability to the crankshaft.

These are mounted on the crank web.

The reason for installing counterweights in the crankshaft is, they

can eliminate the reaction caused by rotation. And it is very

helpful for achieving the higher RPM and makes the engine run

easily.

5. Thrust Washers

At some points, two or more thrust washers are provided to stop the

crankshaft from moving lengthways. These thrust washers assemble

among the machined surfaces in the web and the crankshaft saddle.

With the help of thrust washers, it can be easily maintained the gap and helps to reduce the lateral movement of the crankshaft. In many engines, these are made as part of the main bearings, usually, older types, use separate washers.

6. Oil Passage and Oil Seals

Crankshaft oil passage passes oil from main bearing journals to the

big end journals. Normally the hole is drilled on the crank web.

When the crankpin is in an upward position and combustion forces

push the connecting rod to a downward position, it allows oil to

enter between journal and bearing.

The crankshaft has some extend beyond the crankcase on both ends.

This causes oil to leak from these ends. So, preventing oil from

these openings, oil seals are provided. There are two main oil

seals are connected at the front end and rear end.