SUZHOU KING ENTER IMPORT AND EXPORT CO., LTD. |

|

ETM-20

2Ton / 20kN Computer Controlled

Electronic Universal Tensile Testing Machine

1 Application

This testing machines is equipped with computer, printer, and general test software, to give an accurate determination of metal the material tensile strength, yield strength, the provisions of non-proportional extension strength, elongation, elastic modulus mechanical properties. Test results can print (force - displacement, force - deformation, stress - displacement, stress - deformation, force - time distortion - time) six kinds of curves and related test data, with the software self-test function that can self-diagnose problems. It is ideal testing equipment for the industrial and mining enterprises, scientific research units, universities, engineering quality supervision station. They are perfect testing instrument project quality testing section, universities and colleges, research institution and industrial and mining.

2. Test capability of machine and relevant Standard:

ASTM E8 - 16Standard Test Methods for Tension Testing of Metallic Materials

ISO 6892-1 Materials --tensile testing

3. Main Technical Parameters:

| Model | ETM-20 |

| Max. load force | 20KN |

| Crosshead Travel | 1000mm |

| Effective tensile space | 700mm |

| Effective Test width | 400mm |

| Crossbeam travel speed | 0.001-1000mm/min |

| Testing Specification | ETM-20 |

| Max.load | 20KN |

| Load accuracy | Class 1 (class 0.5 optional) |

| Load range | 1%-100%FS (0.4%-100%FS optional) |

| Load resolution | 1/300000 |

| Deformation Measurement Range | 0.2%~100%FS |

| Deformation accuracy | ≤±1% (≤±0.5% optional) |

| Deformation resolution | 1/300000 |

| Load control speed | 0.01~50 kN/s |

| Deformation control speed | 0.002~0.5mm/s |

| Control Specification | ETM-20 |

| Stress rate | 0.005%~5%FS/s |

| Stress rate accuracy range | When rate < 0.05% FS/s, the precision± 2% When rate ≥ 0.005%FS/s, the precision ±0.5% |

| Deformation rate | 0.005%~5%FS/s |

| Deformation rate accuracy range | When rate < 0.05% FS/s, the precision± 1% When rate ≥ 0.005%FS/s, the precision ±0.5% |

| Displacement control accuracy | ±0.5% |

| Constant load, deformation and displacement control | 0.5%~100%FS |

| Constant load, deformation and displacement control accuracy | Preset value≥10%FN, within the ±0.1% of preset value; Preset value<10%FN, within the ±1% of preset value |

| Clamping Specifications | ETM-20 |

| Tensile grip | Manual Wedge Fixture |

| Round specimen clamping range | Φ4-9mm,(9-14,14-20mm optional) |

| Flat specimen clamping range | 0-7mm,(7-14,14-20mm optional) |

| Compression Plate | Φ100x100 mm |

| Bending fixture | 3 point bending fixture (optional) |

| Electronic Extensometer for metal material | YUU10/50 (optional) |

| Large deformation extensometer for rubber | DBX-800 (optional) |

4. Main Unit Feature:

4.1 Rigid floor-standing frame loading structure with upper space for tensile and lower one for compression and bending test

4.2 Precise ball screws withstand the whole loading with long-life use and compact layout.

4.3 Speed control system is set under the table and comprises the synchronous toothed belt and pulley for high-efficient transmission, which are featured with low noise and maintenance free.

4.4 Fixed crossbeam as upper ones, and sits above the frame and with middle crossbeam as loading beam with smooth travel when testing . The high-accuracy sensor is installed below the crossbeam.

4.5 Load automatic withstanding,, stress, strain control, cycle control and self programming.

4.6 High precision load sensor for guarantee accurate and stable measure

4.7 Wide crossbeam travel speed from 0.05 ~ 500mm / min

4.8 Overload protection: as test force exceeds 2%-5% of the maximum test force of each file, overload protection, it will stop.

5. Components Supply list

| Item | Main body | Material | |

| 1 | Upper beam | 1set | |

| 2 | Cross beam | 1 set | |

| 3 | High precision ball screw | 2 sets | |

| 5 | Servo motor | Taiwan TECO Brand (Japan Panasonic Brand optional) | |

| 6 | Load sensor | China Brand (America Transcell Brand optional) | |

| 7 | Reducers | Taiwan Brand | |

| 8 | Synchronous belt | China Brand 1PC | |

| 9 | Computer | Lenovo, 1PC with LCD screen and all new | |

| 10 | Printer | HPA4 color ink-jet printer, 1PC | |

| Item | Clamping | QTY | |

| 1 | Manual Wedge Tensile fixture (hydraulic automatic clamping fixtures optional) | 1 set | |

| 2 | Round Jaws Φ4-9,(9-14,14-20mm optional) Flat Jaws: 0-7,(7-14,14-20mm optional) | 1 set | |

| 3 | Compression Plate 100x100mm | 1 set | |

| 4 | 3 point bending fixture (optional) | 1 set | |

| 5 | Electronic Extensometer for metal (optional) | 1 set | |

| 6 | Large deformation extensometer for rubber (optional) | 1 set | |

Fixtures pictures

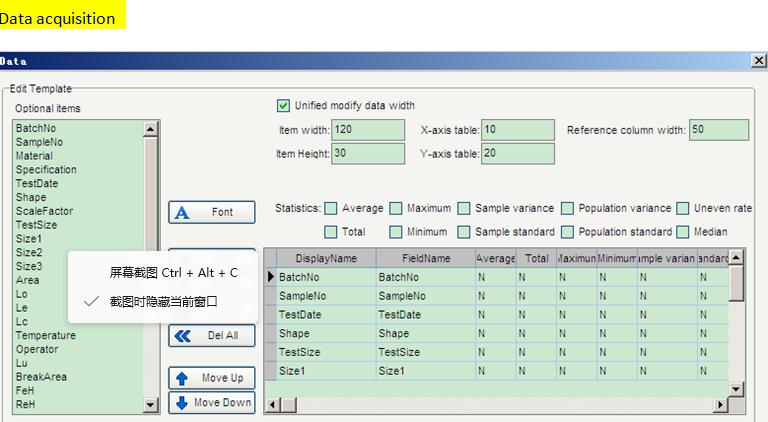

6. Data Acquisition system

61. The data acquisition system of machine consists of two high precision A/D conversion channel and the maximum resolution should be 1/300000 (minimum)

6.2. USB powered data –logger with USB 2.0 and RS- 232 pc interface, 5-keys joystick, 2MB RAM, Automatic recognition facility, Internal signal generator and 12-bit conversion resolution

7 Software

7.1 Batch and report processing program facility in doc and exl format

7.2 The software is fully compliance with the corresponding international standards like ISO, ASTM and GB standards

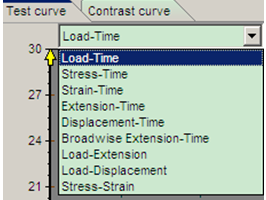

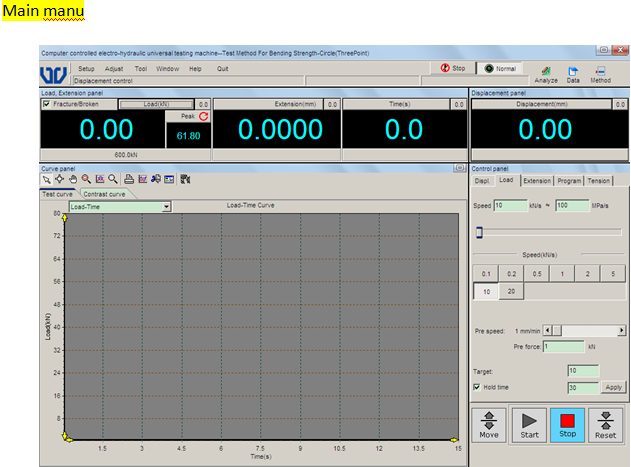

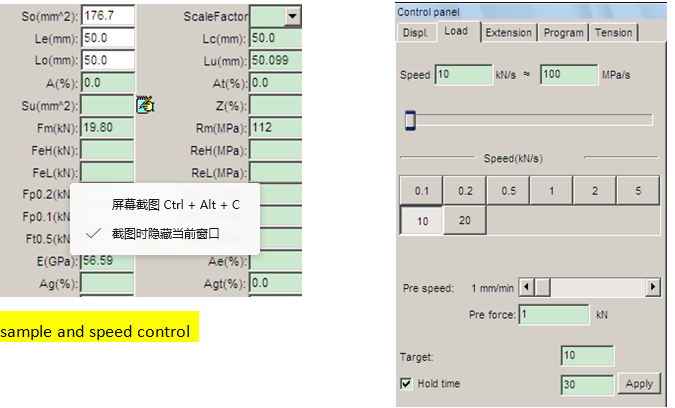

7.3 The control mode of software should contain constant force, constant displacement, constant deformation and others like Stress - strain, force - displacement, force - time, displacement – time

7.4 It supports multiple load cell and extensometer

7.5 Reserved data interface facility, which can be directly connected to integrated management network of laboratory.

7.6 The software is for Windows98/2000/XPAV in7 or higher

7.7 The software supports Real-time record and dynamic display test curve

7.8 The software adopts human-computer interaction to analyze and count performance indicators of materials.

7.9 The software can automatically figure-out routine data such as tensile strength, yield strength, modulus of elasticity, e

FAQ

1. Are your company a trading one or a factory?

Factory + trading company (integration), 21 years focusing on test

instruments field, 5 years exporting experience.

2. After an order is placed, when to delivery?

Generally about 15 working days, If we have inventory, we can

arrange shipment within 3 working days.

Please be aware that our production lead times depend on specific

items and item quantities.

3. What about the warranty with after - sales services?

12 months warranty after delivery. Besides,we can help you to

repair your problem controller freely,even it's not from our

factory. What you need to do is to send us the controller.

After the warranty, the professional after-sale service team will

provide perfect technical support,and help customer solve problems

encountered while using our product, handles guest problems and

complaints in

a professional and timely.

4. What about the services and product' quality?

Each instruments must be carried out 100% quality examination and

test when shipping and delivery goods.

Product use training, each of our product provide video training to

show you how to install & operate.

All the products meet with: ISO, ASTM, AATCC, BS, EN, DIN, JIS and

other required standards.