Shenzhen Pride Instrument Inc. |

|

ISO ASTM DIN shore D Durometer Hardness Tester For Measuring Plastics / Silicone Rubber

Introduction

A reliable instrument for measuring the impression hardness of soft materials such as coatings, plastics and rubber. Equipped with a drag indicator, which holds the highest measured result. Delivery includes metal test block.

Analog durometer is the ideal choice for a wide range of Shore

hardness measuring applications. Durometer displays

hardness readings on an easy-to-read analog

scale calibrated in 0 to 100 Shore units. Other scales

are available: A, C, D, DO, O, OO.

Analog durometer conforms to:

ASTM D-2240, DIN 53505, ISO 868, ISO 7619,

Optional accessoires:

- standard rubber test blocks

- Operation test stand

Durometer type D for materials such as polyester, ABS, nylon, polyurethane, kevlar, acryl, wood, polystyrene etc..

Range: 0 -100 points

Accuracy: 1 point

Dimensions: 102 x 57 x 44 mm

Testing Procedure

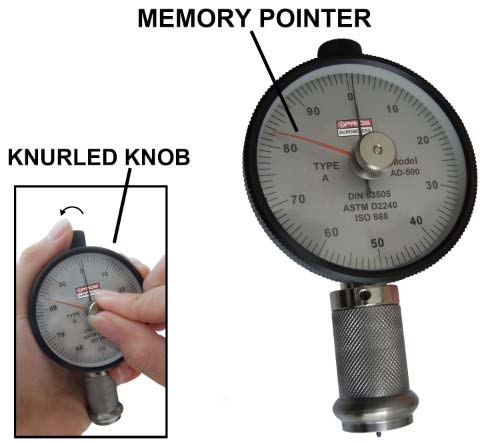

1. Place the instrument on the material to be tested. The durometer must be level and perpendicular to the specimen. Any angle other than perpendicular (90°) may cause errors. The gauge is equipped with the Memory Pointer make sure the pointer is returned to zero before starting.

2. Press the foot of the gauge firmly against the specimen, but not so firmly as to imbed the foot into the surface of the material.

3. Maintain pressure for 2 to 3 seconds. The dial hand gives

the reading in durometer points.

IMPORTANT: After the initial reading has been noted, continue maintaining pressure for several more seconds. Creep or cold-flow of the specimen, if present, will be evident by receding action of the dial hand.

4. Repeat above steps for each use. An example of a properly noted durometer reading: “Durometer A 61, Creep 7 at 15 seconds, 73°F.”

Memory Pointer

The Memory Pointer moves with the measurement pointer when a

measurement is taken.However, when pressure on

the specimen is released, and the measurement pointer

returns to zero, the Memory Pointer

remains in position, marking the last measurement.

To return the Memory Pointer to the zero position prior to taking another measurement, rotate the knurled knob on the face of the instrument counter- clockwise until the pointer has been reset.