Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

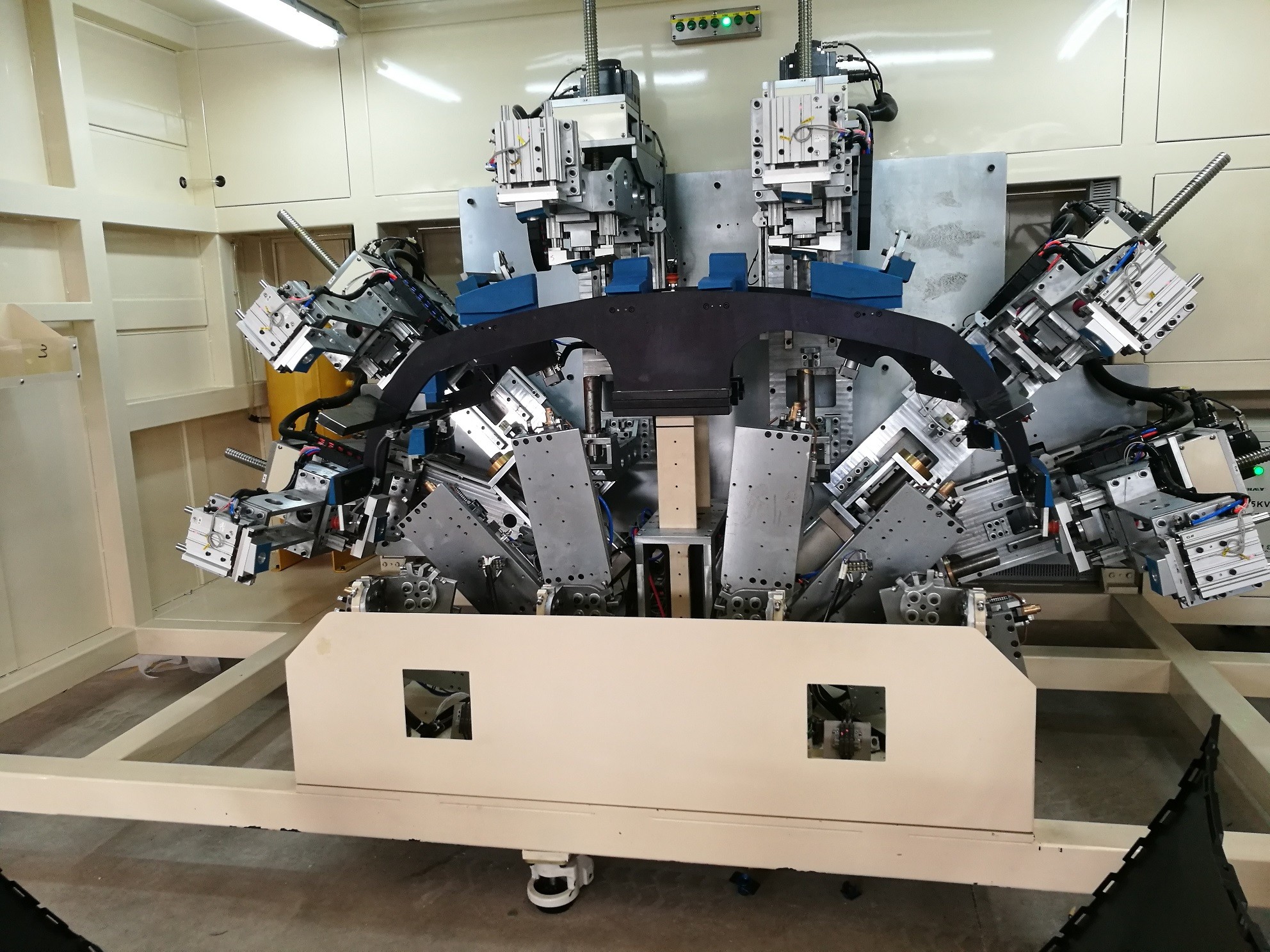

30Khz Ultrasonic Spot Welding Machine For Auto Plastic Parts , Long Life

Description:

Ultrasonic welding is a high-tech technology of sintered plastic products. The use of this technology can replace past production of flux, adhesives, buckles or other mechanical fixation, thereby improving the production efficiency and reduce costs.

The principle of ultrasonic welding is through the ultrasonic generator to convert high-frequency electrical energy into higher frequency mechanical movement, then mechanical movement through a set of amplitude can be changed to the transmission device to the welding head.

The welding head transmits the received vibration energy to the joint portion of the workpiece to be welded, in which the vibration energy is converted into heat energy by friction and the plastic is melted. Ultrasonic not only can be used to weld hard thermoplastics, but also can process fabrics and films.

Specification:

| Gun Type& Cylinder Type | |||||

| Model | HS-40 | HS-35 | HS-30 | HS-28 | HS-20 |

| Frequency | 40khz | 35khz | 30khz | 28khz | 20khz |

| Power | 500W | 500~800w | 500~800w | 500~800w | 500~1000w |

| Horn | ≤10mm | ≤10mm | ≤10mm | ≤12mm | ≤13mm |

| Housing Diameter | 44mm | 44mm | 44mm | 44mm | 64mm |

| Weight of welder | 1.0kg | 1.0kg | 1.0kg | 1.0kg | 1.5kg |

Advantages of Ultrasonic in Auto Industry:

1. Application in riveting, forming and welding

2. Light weight, easy to take, easy to operate (handheld)

3. Equipped with welding timer

4. Easty to set time welding

5. Equipped with an overload protection circuit( Voltage, current, phase, temperature, output)

6. FET power output

7. Automatic resonance

8. Maintain the amplitude function automatically

9. Starting: achieving maximum power with 105msec

Condition of Ultrasonic Welding:

Ultrasonic automotive plastics as the condition of ultrasonic welding, the most important is the time to apply welding energy (vibration, welding time) length and pressure, of course, other conditions are also very important. Welding temperature ultrasonic welding material viscosity flow temperature. Otherwise the material will not melt.

Auto Plastic Parts Welding Principle:

When the ultrasonic role in the thermoplastic plastic contact

surface, it will generate tens of thousands of times per second,

high frequency vibration, this high-frequency vibration, ultrasonic

energy through the ultrasonic wave transmitted to the mold to

ultrasonic welding material surface, it will produce

high-temperature materials. Plastic contact surface resulting in

rapid melting, coupled with stress, it blend and coagulation, so

that to achieve the purpose of ultrasonic welding.

Components of Ultrasonic Welding (Horn, Booster and Transducer):

They can amplify the amplitude at a particular ratio step by step. For example, the transducer amplitude is 6mm, the booster can amplify it triply to 18mm, and then the horn can make it to 36mm. However, the work life of horn would be shortened with the amplification of amplitude. The required amplitude differs with the welding material.

There are three common horn material:

1. Titanium

high price, excellent performance good toughness and low loss, difficult to be processed;

Its amplitude can reach to 60mm.

2. Aluminum

low price, fast loss, easy to be processed;

Its highest amplitude less than 300mm.

3. Steel

too hard to be made as horn;

its highest amplitude less than 25mm;

It is suitable for cutting but the blowpipe need to be added in for its cooling.