Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

500 Watt 35kHz Ultrasonic Spot Welding Machine For Canopy And Tent Material

Gun type: in accordance with the shape design of human body engineering, ultrasonic start switch is located on the trigger, easy to grasp and use the welding operation, especially suitable for horizontal or vertical.

Cylinder type: for the appearance of design straight, ultrasonic start switch is located outside the cylinder, easy welding and hand carried, can also be installed between the on machine, welding operation for each direction.

Specifications:

| Gun Type& Cylinder Type | |||||

| Model | HS-40 | HS-35 | HS-30 | HS-28 | HS-20 |

| Frequency | 40khz | 35khz | 30khz | 28khz | 20khz |

| Power | 500W | 500~800w | 500~800w | 500~800w | 500~1000w |

| Horn | ≤10mm | ≤10mm | ≤10mm | ≤12mm | ≤13mm |

| Housing Diameter | 44mm | 44mm | 44mm | 44mm | 64mm |

| Weight of welder | 1.0kg | 1.0kg | 1.0kg | 1.0kg | 1.5kg |

Product Characteristics:

1. The product design is reasonable, and it is convenient for hand-held operation.

2. Digital Generator, equipped with a professional cooling system to improve the stability of the equipment.

3. It can be used for the welding and riveting of thermoplastic products and the inlaying and process of metal parts between plastic parts. It has completely replaced the process of organic melting agent, and has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, firm welding and convenient operation.

4. Not only can be used to weld metal, hard thermoplastics, but also fabrics and films. The hand-held ultrasonic welding gun can replace different ultrasonic welding heads according to the size of the riveting point of the product to be welded and the welding requirements, which is quick and convenient, and the cost is much lower than that required for the ultrasonic welding machine dedicated to the automobile door panel, which is convenient to meet different requirements. Customer demand.

5. Aluminum alloy precision casting shell, high strength, good heat dissipation performance, greatly extending product life.

6. High-tech surface technology treatment, corrosion resistance, impact resistance, no rust.

With successful high-quality transducers, the power is nearly double of similar products on the market.

7. Add professional cooling system to greatly improve product stability.

8. CNC power drive, automatic frequency search, power 100% adjustable.

9. The professional anti-shock technology is more lightweight and more precise.

Components:

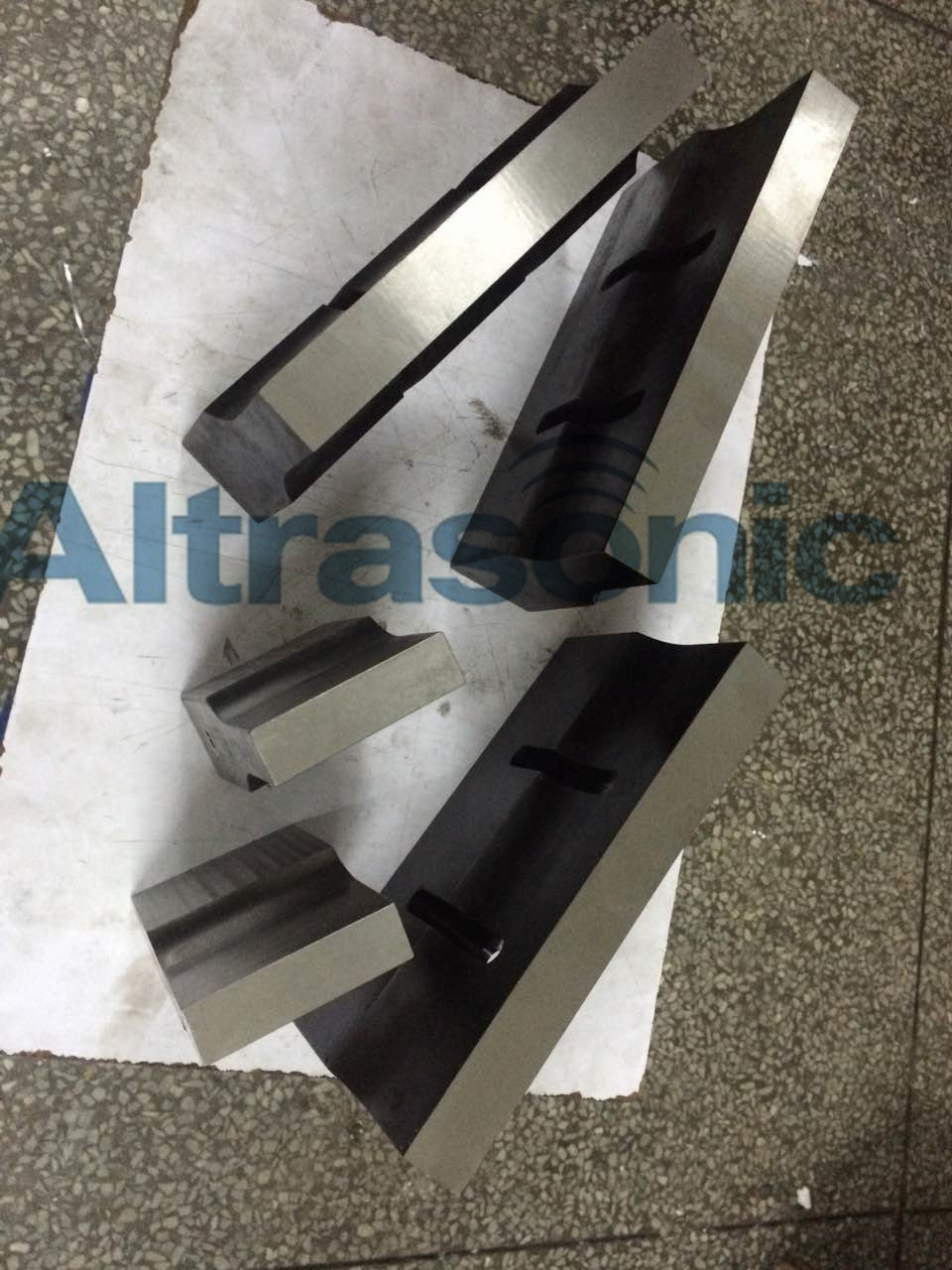

Ultrasonic Transducer

It can transfer high-frequency electricity energy to machine vibration energy.

Welding Horn

It used to send the machine energy and pressure to the working matter.

Protective Sleeve

It is a sleeve that can protect some parts in it.

Digital Generator

It can transfer the 50-60Hz city electricity to high-power’s high-frequency (15kHz-100kHz) power supply, and then provide to the transducer. It can adjust its frequency automatically according to transducer, with LCD touch panel,easy operation.

Technical Parameter:

| Frequency | Horn | Power | Voltage | Generator | Tuning Method | Type |

| 35Khz+200hz | Working Surface Diameter ≤12mm, Aluminum or Titanium material | 300w | 220v/110v | Digital generator | auto tuning | gun/cylinder |

| 35Khz+200hz | Aluminum or Titanium material, can be design as per 3D drawing | 800w | 220v/110v | Digital generator | auto tuning | gun/cylinder |

| 35Khz+200hz | Aluminum or Titanium material, can be design as per 3D drawing | 1200w | 220v/110v | Digital generator | auto tuning | gun/cylinder |

Frequency available in 28kHz, 30kHz, 35kHz, 40kHz and OEM.

Applications:

Plastic hardware riveting, spot welding, embossing, folder

positioning and other processes,

decoration, ribbon welding etc. for textile industry.

Precautions:

1. The equipment has been debugged to the best condition before leaving the factory. Do not disassemble the torch housing or the power supply housing when using it.

2. The equipment must be kept clean during use to prevent dust and moisture from entering.

3. The device is designed with a micro switch on the outer casing and the handle. It can be operated by touching the switch during use. Do not work for a long time without any load, otherwise the equipment may be damaged.

Affecting Factors in Ultrasonic Welding:

Ultrasonic automotive plastics as the condition of ultrasonic welding, the most important is the time to apply welding energy (vibration, welding time) length and pressure, of course, other conditions are also very important. Welding temperature ultrasonic welding material viscosity flow temperature. Otherwise the material will not melt.