Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

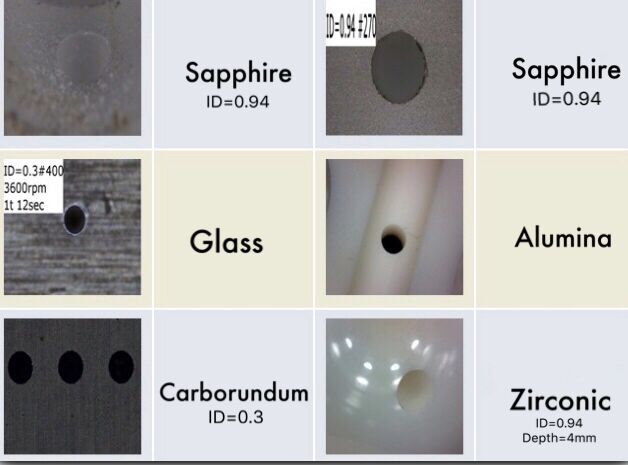

High-speed MicroMachining Ceramics with Rotary Ultrasonic Machining

Technical Parameters:

Resonance point amplitude: 10um or more;

Max Speed: 30000 RPM

Matching tool: carbide end mill head Φ2-Φ13; disk cutter Φ50;drilling hear Φ1~6

Power: 500W

| Frequency | 20 Khz/40khz |

| Output Power | 500 W |

| Voltage | 220 V |

| Switch | Handle or foot switch |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weight | 30 KG |

| Application | Ultrasonic drilling,milling grinding |

| Generator | Digital Generator |

| Length of cable | 5M |

Ultrasonic drilling:

Ultrasonic assisted drilling is a recently-developed technique, in which high-frequency (> 20 kHz) vibration is superimposed onto the movement of a standard drill bit in the axial direction, providing advantages including reduced drilling forces (reduction often in excess of 80%) and improved quality of drilled holes when compared to conventional drilling. Ultrasonic assisted drilling also achieves a reduction in entry and exit delamination size, but not in the expected proportion considering the observed reduction of drilling forces. A different mechanical process to that in conventional drilling may be driving the delamination in Ultrasonic assisted drilling, for example dynamic or thermal effects in addition to thrust and torque loads.

Competitive Advantages:

Applications:

Workshop:

CE Certification:

Packing&Shipping:

Payment: