Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

Consumer Industry Ultrasonic Geometry Welding Tightness Mark-free

Surface

Description:

The HS-X20P series of ultrasonic welder offer a compact design to

conserve work space,and is easy for operation and maintenance to

achieve an outstanding cost-performance.

The HS-X20P series of ultrasonic welder is using a mechanical

control and accurate duplication of welder parameters setting

design for a more stable and reliable weld performance, suitable

for more industrial applications.

Technical Parameters:

| Item No | HS-X20P |

| Frequency | 20Khz |

| Power | 1500W |

| Voltage | 200-240V, Alternating current |

| 50-60hz, Single phase | |

| Electric current | 10A |

| Range of welding time | 0.05-10/sec |

| Environment Temperature | 5-50℃ |

| Air supply requirements | Clean dry compressed air, maximum pressure 7kg |

| Maximum pressure | 1.96KN |

| Maximum stroke | 100MM |

| Beats | 80CPM |

| Operated mode | Time mode or Energy mode |

| Weight | 110Kgs |

Consumer industry applications:

Using ultrasonics, consumer components can be produced and joined

in a cost-effective way; at the same time, the process provides

great flexibility in terms of design. High requirements for visual

appearance, production speed, or geometry are met.

Principle:

Transmitted ultrasonic energy through welding parts to welding

area, local high temperature will happen due to high acoustic

resistance between two welding interface places. Also, no enough

time dissipating out heating energy timely because of poor plastic

thermal conductivity, heating energy gathered in welding area since

could not dissipating out timely, the two plastic contact areas

will welt rapidly, coupled with a certain pressure, it makes fusion

to one unite. When ultrasonic stop function, and keep the pressure

sustain to make its solidification molding, finally forming a

strong molecular chain, which achieve the purpose of welding. And

the welding strength can close to raw material body strength.

Main advantages:

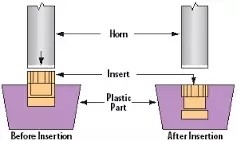

INSERTING

Threaded inserts, grub screws or other parts can be ultrasonically

embedded in thermoplastics.

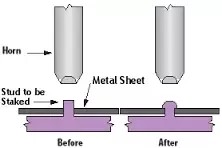

STAKING

Melting and forming of a plastic stud to retain or lock another

material, often dissimilar, in place.

SPOT WELDING

Used for joining two thermoplastic parts with no pre-formed hole or

energy director. This technique is particularly suited to large

parts or parts with complicated geometry and thermoformed or

blow-molded parts without a joint.

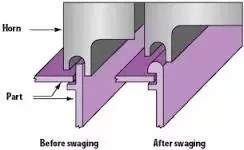

SWAGING

Used to capture another component of an assembly by melting and

reforming a ridge of plastic around the component. The ridge locks

the second component in place without welding the materials

together.

Consumer Industry Ultrasonic Geometry Welding Tightness Mark-free

Surface

Workshop:

CE Certification:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast

delivery.Usually 1-3days if we have in stock.

Payment:

Quality control:

3 times old test to confirm the products is well quality.

20 technician work together , and learn together , to improve our

products.

48 hours working time to test the stability of our product before

sending out.

Tag:ultrasonic plastic welder