Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

Melting and Forming of A Plastic Stud to Retain or Lock Another Material by Ultrasonic Staking

Specifications:

| Gun Type | Cylinder Type | ||||||||

| Model | HS-35G | HS-28G | HS-28G | HS-20G | HS-35C | HS-28C | HS-28C | HS-28C | |

| Frequency | 35k | 28k | 28k | 20k | 35k | 28k | 28k | 28k | |

| Power | 700&1000 | 300&500 | 400&700 | 900 | 700&1000 | 300&500 | 400&700 | 500&800 | |

| Horn | ≤10mm | ≤10mm | ≤12mm | ≤13mm | ≤10mm | ≤8mm | ≤12mm | ≤12mm | |

| Housing Diameter | 51mm | 64mm | 40mm | 40mm | 45mm | 60mm | |||

| Handle Size | 100mm×45mm×32mm | —— | —— | —— | —— | ||||

Weight Without Wire and Horn | 0.6kg | 1.3kg | 1.3kg | 1.5kg | 0.6kg | 0.6kg | 0.6kg | 1.3kg | |

| Digital generator | ● | ● | ● | ● | ● | — | ● | ● | |

| Analog generator | ● | ● | ● | ● | ● | ● | ● | ● | |

Definition of Ultrasonic Staking:

Ultrasonic staking is suitable for the positive joining of thermoplastics together or

to non-plastics.

The main difference between ultrasonic welding and ultrasonic staking lies in the fact that when riveting melting deformation occurs and

only one of the two joining sections is plasticised. This makes it

possible to join any thermoplastics that are not polymer compatible

to each other or to non-plastics. As a result, the riveted joins

are almost free from play, because the cold riveting tool allows

the fused rivet head to cool under pressure.

Ultrasonic staking is also very efficient and at the same time saves energy.

The technology is used mainly where fusion welding is impossible,

where metal parts are to be inserted into plastic casings or where

the join is not subsequently visible.

Applications:

Electronic and electrical appliances, auto parts, clothing and packaging, textile industry, environmental industry, medical equipment,the toy industry, communications equipment and other industries.

| Toy industry | Plastic toys, water guns, aquatic life video game, children dolls, plastic gifts, etc |

| Electronic products | Recording, audio tape boxes and core wheel, disk enclosure, board of mobile phone batteries and rectifier transformers, switches and sockets, remote control, electronic swatter, pseudo-imitation caps, etc |

| Household appliances | Electronic clock, electric trumpeter hairdryer, steam iron water tank, electric kettle air-hsiang, computer, etc |

Stationery, daily necessities | Stationery, aquarium ruler, the raphe folder and shell, pen stand, cosmetics box shell,the end of the toothpaste tube seal, mirror, insulated cup, lighter, seasoning bottles sealed container |

| Car, motorcycle | Battery, front corner lamp, rear tail light, instrument, reflectors, automotive manual welding jacket, the car door welded baffle welding, automobile, car mats welding, automotive bumper repair welding |

The application of the sports industry | Table tennis, table tennis bats, badminton rackets, tennis rackets, golf clubs, pool table, treadmill roller rope skipping handle stepper, treadmill accessories, box jumps,gymnastics mats, boxing gloves, boxing sandbag Sanda protective gear, the path to indicate the brand, the X Display Stand and other sports equipment, etc |

| The packaging industry | Hollow crate welding, ziplock welded |

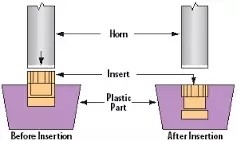

INSERTING

Threaded inserts, grub screws or other parts can be ultrasonically

embedded in thermoplastics.

STAKING

Melting and forming of a plastic stud to retain or lock another

material, often dissimilar, in place.

SPOT WELDING

Used for joining two thermoplastic parts with no pre-formed hole or

energy director. This technique is particularly suited to large

parts or parts with complicated geometry and thermoformed or

blow-molded parts without a joint.

SWAGING

Used to capture another component of an assembly by melting and

reforming a ridge of plastic around the component. The ridge locks

the second component in place without welding the materials

together.

Competitive Advantage:

Rapid sonotrode exchange

High quality, heavy duty aluminum housing

High frequency and control cable to the ultrasound generator are in a strong and highly flexible braided plastic sheet

Timer-controlled air cooling as an option

Mobile – can be transported by handle on the generator case

Welding Large Parts with Complicated Geometry and Thermoformed or Blow-molded Parts without A Joint

Workshop:

CE Certification:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Quality control:

3 times old test to confirm the products is well quality.

20 technician work together , and learn together , to improve our products.

48 hours working time to test the stability of our product before sending out.

Tag: ultrasonic spot welder,sonic welding machine