Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

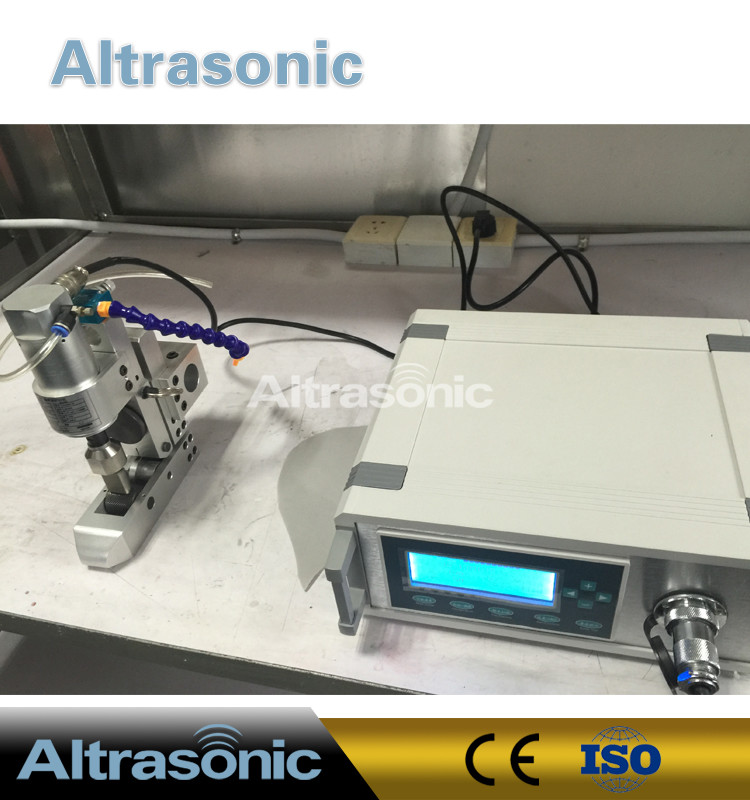

Robotic Operated Ultrasonic Sealing and Cutting Machine Installed in Robotic Arm

Description:

Compact Ultrasonic hand-held cutting unit for cutting of fabrics, non-woven materials, foils etc. Ideal for straight and curved cutting. With guiding rail on a cutting table the ideal cutting unit also for larger series.

Cost-efficient Ultrasonic Cutting equipment for studios, small and medium-sized enterprises. At best adequate for single cuts as well as for small up to medium series.

Specification:

| FREQUENCY | 40Khz |

| POWER | 500W-800W |

| INPUT | AC110-240V, 50/60Hz |

| POWER CONTROLLER | stepping or continuous |

| MATERIAL OF CUTTING HEAD | aluminum alloy, stainless steel, titanium alloy, alloy steel. |

| MACHINE WIGHT | 4 kg-16 kg |

| ACCESSORIES | foot switch, additional blade |

| COOLING DEVICE | compressed air mouth can be installed. |

| CABLE LENGTH | 2M or customized |

| FOOT SWITCH | available |

Principle:

With ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds. With ultrasonic sealing heat is generated at the inside of the film, not by heat input from the outside as is the case with heat sealing, for example. The tools (sonotrode and anvil) that come into direct contact with the packaging material, remain cold during the entire weld process. The support layer remains almost cold and upon termination of energy input, the heat dissipates faster to the outside due to the temperature difference between the support layer and the sealing layer so that the hot-tack resistance is significantly higher.

Applications:

1. For thermal plastic gate cutting and flush cutting.

2. For non-woven or woven cutting,textile cutting, fabric cutter,

curtain cutting,window blind fabric

3. For rubber, PVC, leather plastic, cardboard, acrylic,

polyprolene and so on cutting.

4. For tape and film cutting .

5. For paper cutting,printing industry cutting.

6. For package material cutting

7. For the automotive industry cutting

Competitive Advantage:

1. Cut the material quickly and precisely

2. Smooth and traceless cutting edge

3. Powerful, effective realiable

4. Low cost, easy operator. An operator only handle the probe and step the foot switch.

Robotic Operated Ultrasonic Sealing and Cutting Machine Installed in Robotic Arm