Hangzhou Altrasonic Technology Co., Ltd |

|

Verified Suppliers

|

|

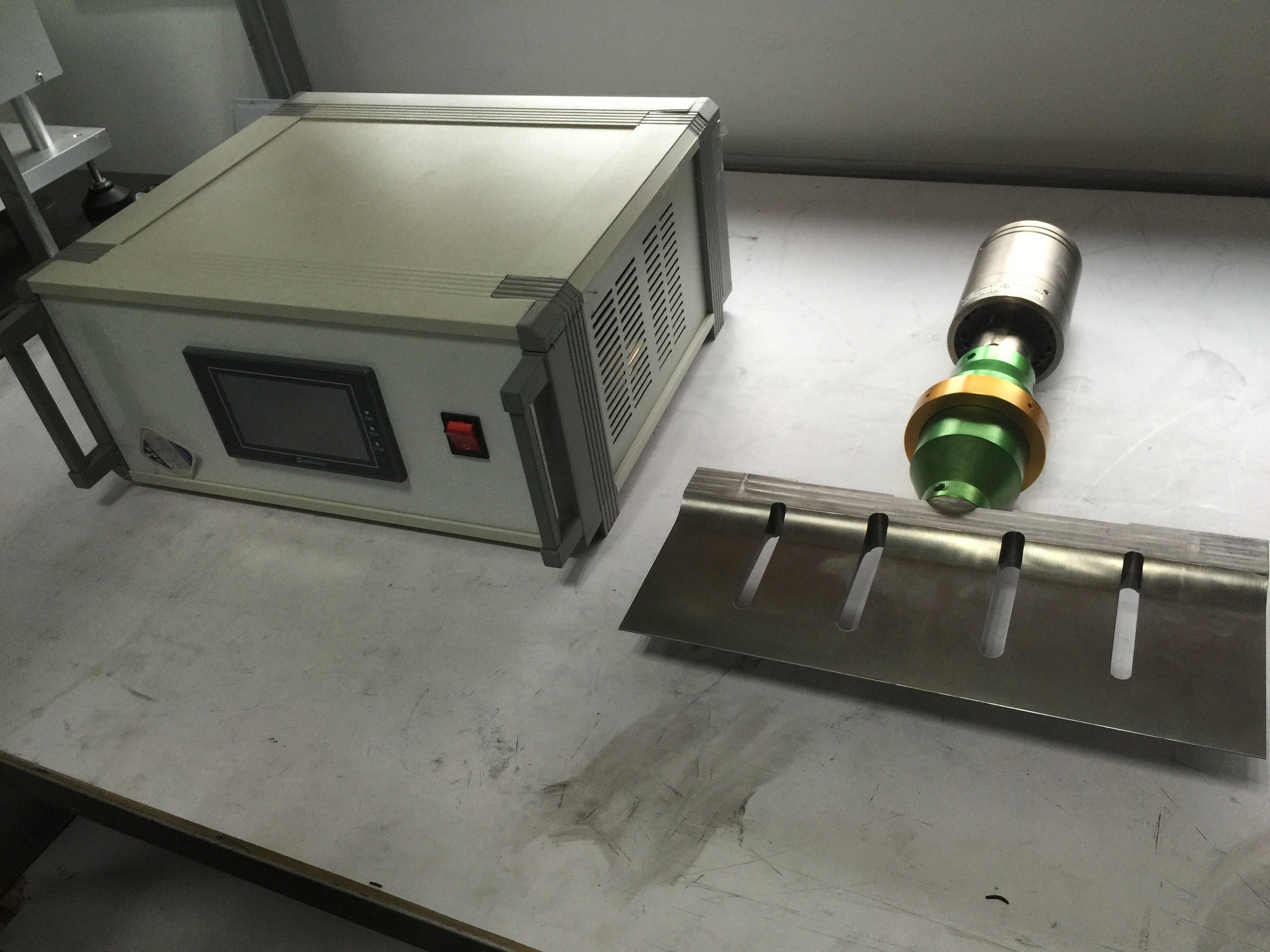

Blade Length 255mm Titanium Ultrasonic Food Cutter with External Air Cooling and PLC control System

Description:

The ultrasonic food cutting machine (cutter) is composed of ultrasonic transducer (converter) with cover, booster, titanium blade and digital generator.

Ultrasonic cutters can smoothly cut difficult-to-cut materials.

They are small in size and do not require large installation areas.

Special equipment is not required for the installation. They are

small enough to be hand-held for many operations. They can also be

attached to automated machinery arms. Although they may not be

familiar to you, they play an active role in the manufacturing

processes of various industrial products which we use daily.

The ultrasonic cutter is composed of a “transducer” that generates vibration and an “oscillator” that drives the transducer. A piezoelectric element is used for the transducer. When voltage is applied, the piezoelectric element displaces the transducer by a few micrometers. Periodically applying voltage generates vibration. Each object has its special frequency, by which the object is stable and easy to vibrate. By adding an external force that corresponds to that special frequency, a small force can obtain a large vibration. This phenomenon is called resonance.

In the ultrasonic cutter, the piezoelectric element generates a force that resonates the whole body, from the transducer to the blade tip, generating a large vibration at the tip. The oscillator periodically generates voltage to resonate and drive the transducer. Using a component of the ultrasonic cutter called the horn to wring the cross-sectional area, from the piezoelectric element to the blade tip, can obtain a larger vibration.

Parameters:

| FREQUENCY | 20Khz |

| POWER | 800W |

| INPUT | AC110-240V, 50/60Hz |

| POWER CONTROLLER | stepping or continuous |

| MATERIAL OF CUTTING HEAD | , stainless steel, titanium alloy, alloy steel. |

| MACHINE WIGHT | 15~18KG |

| ACCESSORIES | foot switch, additional blade |

| COOLING DEVICE | compressed air mouth can be installed. |

| CABLE LENGTH | 3M or customized |

| FOOT SWITCH | available |

Advantages:

Blade Length 255mm Titanium Ultrasonic Food Cutter with External Air Cooling and PLC control System