Hangzhou Powersonic Equipment Co., Ltd. |

|

Verified Suppliers

|

|

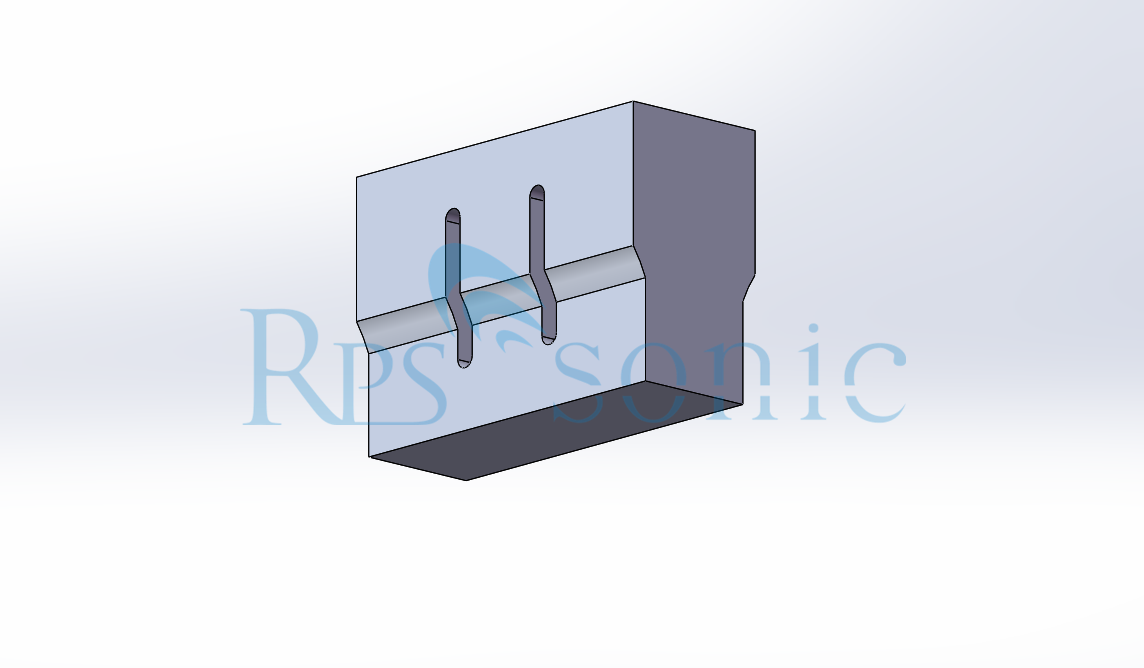

Solving the performance parameters of welding horn

Parameter:

| Item | parameter |

| Frequency | 15Khz |

| Welding area | 127*33mm |

| Material | Alumium alloy |

| Connect screw | M16 |

ultrasonic weldind horn

The ultrasonic welding horn is the contact interface between the ultrasonic welding machine

and the material. Its main function is to uniformly and effectively

transmit the longitudinal mechanical vibration output from the horn

to the material. The materials used are usually high-quality

aluminum alloys or even titanium alloys. Because the design of

plastic materials changes a lot, and the appearance varies widely,

the horn also changes accordingly. The shape of the working surface

must be well matched with the material, so that the plastic is not

damaged during vibration; at the same time, the first-order

longitudinal vibration must be coordinated with the output

frequency of the welding machine, otherwise the vibration energy

will be consumed internally. When the horn vibrates, stress

concentration will occur locally. How to optimize these local

structures is also a problem to be considered during design.

The forms were compiled and programmed using Microsoft Excel spread

sheet software. The basic information that needs to be input when

solving includes the working frequency, material, density, Young's

modulus, wave velocity, Poisson's ratio, wide-end diameter and

narrow-end diameter of the welding horn. Spreadsheets

simultaneously solve and feedback exponential, catenary, conical

and stepped welding horn with commonly used description parameters

such as magnification factor, resonance length, displacement nodes,

and locations of stress maxima. The difference between the

calculation results of the four types of welding horns with the

same initial conditions can be visually identified through the

table. More ideal calculation results can be obtained by

continuously adjusting the initial conditions (mainly by adjusting

the external dimensions and examining the theoretical amplification

factor of the horn).

Parameterized drawing of ultrsonic welding horn

In order to meet the needs of further drawing or designing of

ultrasonic welding horn, Excel spreadsheets calculate the overall

dimensions and key point coordinates of various welding horn,

combined with the language rules of Au-toLISP and ANSYS APDL

parametric secondary development design software, and automatically

compile parameters Modeling program. Enter the modeling program

into the command window of AutoCAD and ANSYS engineering design

software to complete the plan drawing and 3D modeling of the

welding horn, and provide horn drawing or finite element analysis.

The design uses hard aluminum as the horn material, and enters the

wide-end diameter D1 and narrow-end diameter D2 for trial and

error. Obviously, with the same cross-section dimensions at both

ends, the stepped horn is easier to obtain high gain. Determine the

horn magnification factor and resonance length for both end face

diameters after leaving margin for end face avoidance

Comparison of finite element analysis

Using the ANSYS APDL parametric modeling program obtained in the

example, the modal analysis is performed in the AN-SYS environment.

The model was meshed with SOLID95 elements, and a total of 9,670

elements and 14,786 nodes were generated, which were solved using

Lanczos algorithm. The first-order longitudinal vibration frequency

of the horn is f = 20044Hz.

Why RPS-SONIC HORN:

1. Every horn will be designed by FEA system , so that to confirm the End face of the ultrasonic horn with uniform force

2. All ultrasonic horns with three months warranty.

3. Specialized in high power ultrasonic for more than ten years

4. Every ultrasonic horn with 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Service and shipment