Mitech CO.,LTD. |

|

Multifunctional Magnetic Particle Flaw Detector , Dc Magnetic Flaw Detection Ndt Equipment

Magnetical Flaw Detector CJX-A

Description:

I. General Description

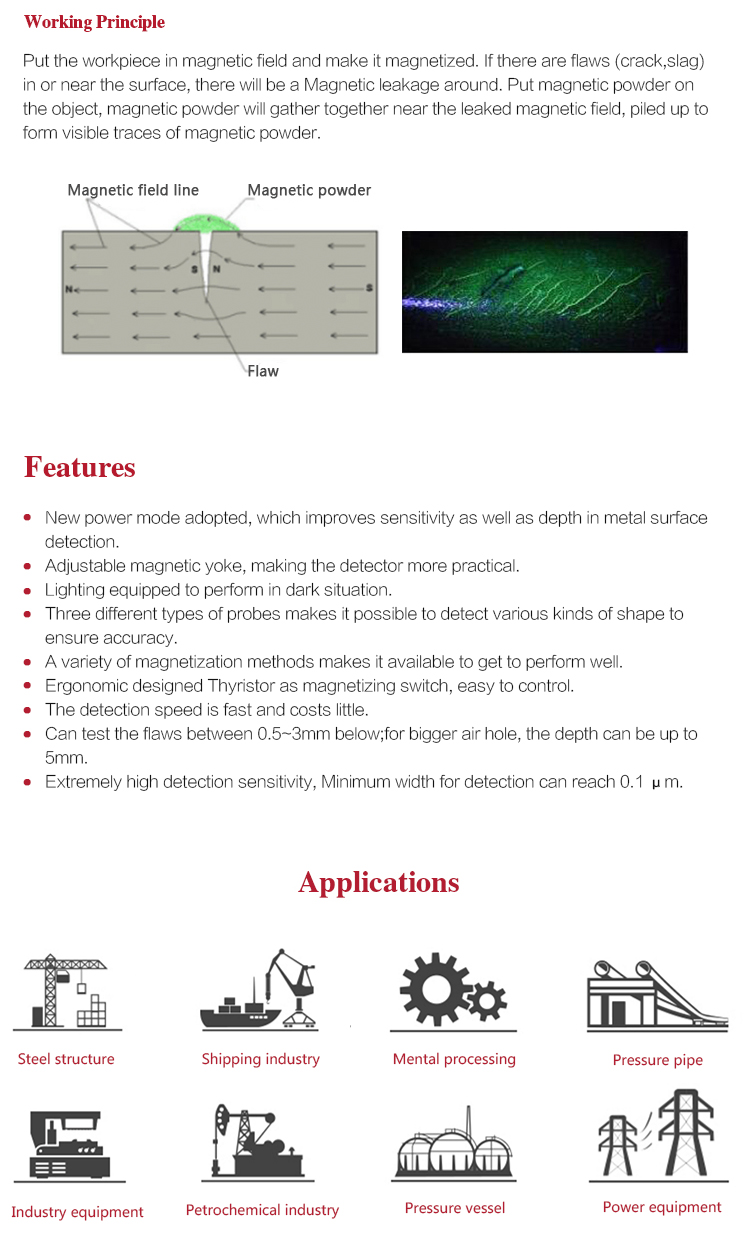

CJX-A Magnetic Particle Tester is our newly-developed equipment for the testing of casting quality using magnetic particles and features a combination of advantage of various overseas and domestic equivalent products. It features an imposed magnetic field and thus is compact and lightweight. The highly integrated circuit adopted has rendered our product a combination of all functions of various types of equipment.

* Options

A-shaped detecting head: it is also named horseshoe magnetic yoke detecting head or weld detecting head and features a movable inclined magnetic head. It has one working lamp and is especially applicable for the testing of irregular surfaces and work pieces. The pole distance is 20-160mm; hoisting capacity: AC≥5kg and DC≥18kg; weight: 1kg. This kind of detecting head is adopted by the Horseshoe Magnetic Yoke Tester or Angle Weld Tester. It features a wide scope of application with the movable detecting head.

D-shapeddetecting head: it is also named electromagnetic yoke detecting head with multiple movable joints and strong magnetism. Pole distance: 60-220mm, hoisting capacity: AC≥6kg and DC≥20kg; weight: 1.6kg. This kind of detecting head is adopted by Electromagnetic Yoke Tester whose magnetic head features strong magnetic conductance and magnetization.

O-shapeddetecting head: it is also named ring-shaped detecting head; inner

diameter 150mm, central magnetic field ≥ 1,800e, weight: 3kg. This

kind of detecting head is adopted by the Ring-shaped Tester which

works on the principle that strong magnetic fields are created

while windings are electrified. It is applicable for the casting

quality testing and demagnetization of irregular work pieces like

shafts, bars, pipes and vanes, etc.

O-shapeddetecting head: it is also named ring-shaped detecting head; inner

diameter 150mm, central magnetic field ≥ 1,800e, weight: 3kg. This

kind of detecting head is adopted by the Ring-shaped Tester which

works on the principle that strong magnetic fields are created

while windings are electrified. It is applicable for the casting

quality testing and demagnetization of irregular work pieces like

shafts, bars, pipes and vanes, etc.

II. Technical Performance

1. Power supply: AC 220 ±10% 50HZ 5A

2. Output: AC 38V 6A A, D, O-shaped detecting heads are applicable

3. Testing speed: ≥6m/min

4. Detecting head temperature rise: ≤60℃

5. Working intervals: In the case of continuous operation for a long time, it is recommended: Magnetization time: ≤3 sec; interim: ≥5

6. Instrument weight: about 5.5kg

III. Operation and Maintenance

Please read the Operating Instructions carefully before operation to master the structure and technical performance of the instrument and check if the power supply is applicable for the instrument and the connection is proper. Switch on the power only after everything is checked proper. Check if the instrument is in a sound condition when the instrument is used for the first time or has been out of operation for long.

1. Operating steps:

(1) Connect the plug to the power supply socket and then connect the detecting head to the output socket.

(2) Switch on the power to turn on the indicator light, connect the instrument control circuit and enable the servo.

(3) Keep a good contact between the detecting head and the work piece and turn on the switch on the detecting head. Then the instrument will be magnetizing the work piece and the working lamp will be on. Then release the switch to cut off the power supply and stop the magnetization;

(4) Please switch off the mains switch after use.

2. Troubleshooting

(1) The indicator light remains off and the tester does not work after the mains switch is turned on. The fuselage is broken due to short circuit or overload.

(2) The indicator light remains off after the switch is turned on and the detecting head is working. The indicator light fails.

(3) The indicator light is on but the detecting head does not magnetize. There is something wrong with the main circuit or control circuit.

(4) Switch on the power and magnetization is enabled even without turning on the magnetization switch. There is something wrong with the control circuit or bidirectional controlled silicon.

IV. Precautions

(1) Working intervals: In the case of continuous operation for a long time, it is recommended: Magnetization time: ≤3 sec; interim: ≥5

(2) Check if the power supply voltage is applicable for the instrument before operation as either overvoltage or undervoltage will damage the instrument or affect the test result.

(3) The detecting head shall maintain a good contact with the work piece before turning on the magnetization switch as the magnetizing effect will be optimal then.

(4) Although this instrument features a sound overload protective circuit, operation with empty load shall be avoided as much as possible to eliminate unnecessary temperature rise.

(5) The instrument is capable of continuous operation. Stop the instrument if overtemperature is detected and have a troubleshooting before using it again.

(6) The instrument and its accessories shall be used or stored where it is clean, dry and corrosion-free.

(7) Please beware of high voltage in the instrument during troubleshooting.

(8) Do not turn on or turn off the mains switch when the magnetization switch is pressed down.

(9) The instrument case must be reliably grounded.

(10) Please send the instrument to our Service Center for repairing if the electric faults can’t be repaired by you.