Mitech CO.,LTD. |

|

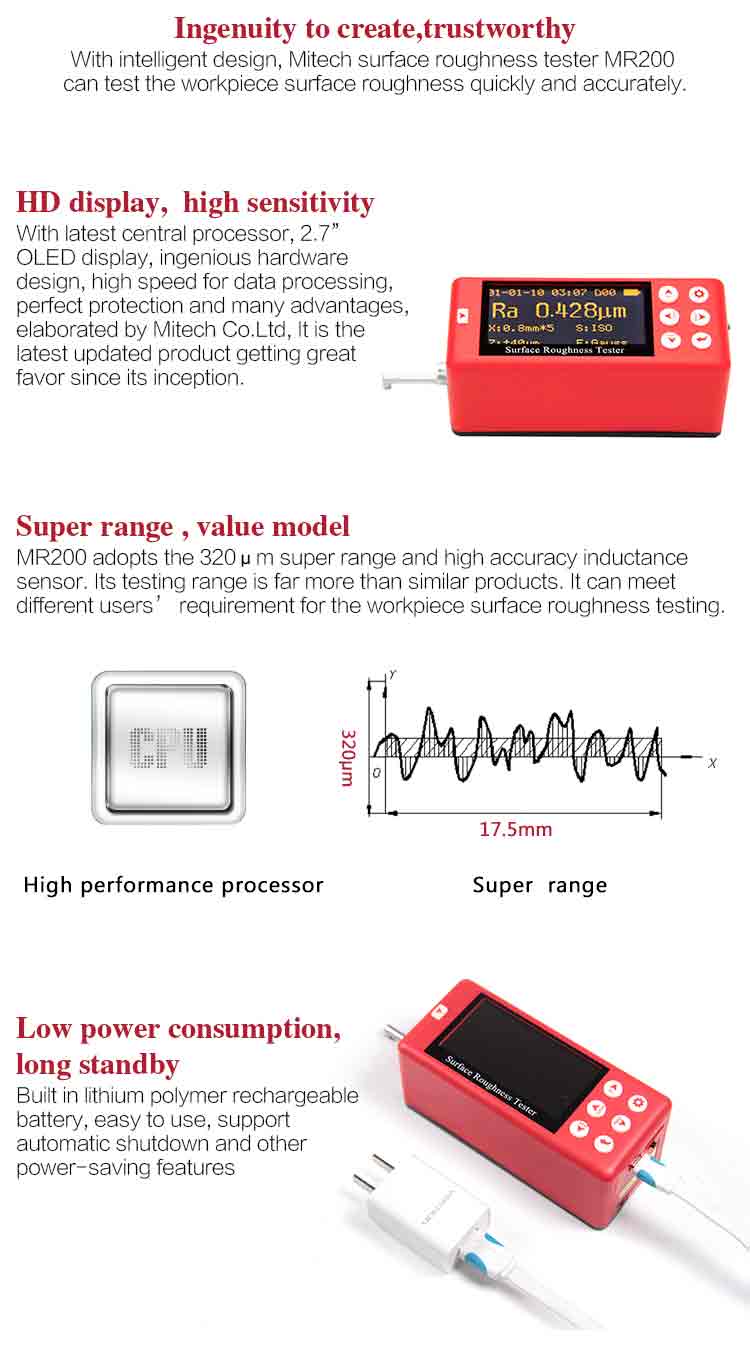

Surface Roughness Tester MR200 with super range and low power consumption

The MR200 surface roughness tester is a new upgrade instrument which adopts the newest processor. This instrument adopts 2.7 inch OLED display, combines accurate measurement, exquisite design, fast process rate and complete protection in one host. It is highly favored by users since it was produced, it has large measurement range, superior than other similar products and can meet different needs of users. By connecting with Micro-USB port, Bluetooth, SD card, it can do wireless remote control, measurement, print and communicate with PC and store massive data. It has been widely used in the quality control process of various precision metals, plays an important and necessary role in rising production qualification rate and saving cost.

Operating Method and Attentions

Operating Method and Attentionsoperation instruction,

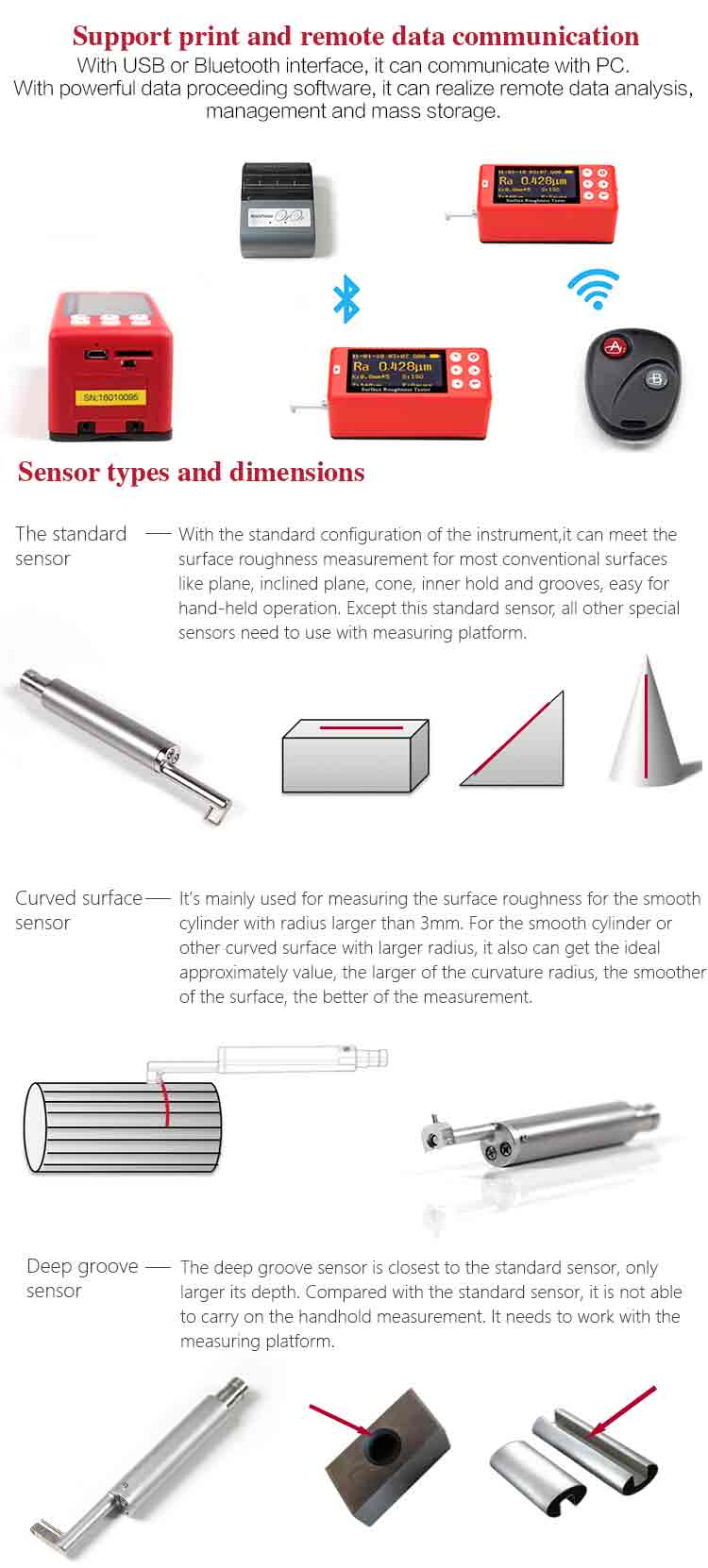

① Plugging the probe carefully into the instrument, install it on the connecting part of the pillar;

② Using the curved surface probe, we should try to use a shorter range, such as 0.25um

sampling length especially when the arc is small;

③ Raise the slide adjustment rack of pillar slightly above the work piece surface, fall the probe till

contact with the work-piece. In the process, you should be careful especially when the probe is about to touch the work-piece;

④ Make the probe stylus point at the surface peak (or lowest point);

⑤ Adjust the body of the probe to the visual level state, observe whether the stylus position is

near the center;

⑥ Before measurement, move the work-piece to the right half of the measuring range, press start

Indication calibration,

Use the single-scale line for calibration