Hangzhou Powersonic Equipment Co., Ltd. |

|

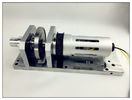

Fabric melt-blown and PP roll seam ultrasonic welding / sewing machine

Ultrasonic welding with the Seamsonic is a economic and conventional sewing technology. No needle thread, no flash.

If assembling of laminates, clothing fabrics with high share of polymer and technical non woven is required and in particular to get, the use of the Seamsonic is the first choice.

Check video on YouTube https://youtu.be/4OUA1nB8ZW8

Characteristics

1.Seaming,trimming and embossing without glue, thread or other

consumables

2.More faster and cost effective .

3.Eliminates fraying or unraveling of bonded edges and seams

4.Multifunctional and thousands of designs available

5.Welded edge can be Customized pattern and more beatutiful.

6.Requires minimum training and maintenance

7.Super strong ultrasonic power meets the needs of different fabric

thickness

8.Labor cost and time savings

RPS-SONIC specializes in manufacturing ultrasonic seam welding solutions for rotational systems.

There are two types of rotating modules for these operations: with either a side or central sonotrode resonating at a 35 kHz frequency and power varying from 600W to 1200W.

These horns can be made out of aluminium, treated with a special surface strengthening procedure, or titanium.

Our seam welding solutions are employed in binding synthetic textiles such as PVC, polyester, polypropylene, coated, filtering and technical fabrics.

| Item | Rotary horn | Flat horn |

| Frequency | 35Khz | 20Khz |

| Power | 500W | 1500W |

| Horn Photo |  |  |

| Horn material | Titanium alloy | Steel horn |

| Advantage | Titanium alloy, more stable Longer using life Welding flatter | economic welding by ultrasonic

|

| Disadvantages | Expensive | material transfer to be flat |

APPLICATION:

An ultrasonic sewing machine is versatile and easy to use in order

to seam, cut, slit, trim, tack, emboss, or to cut and seal at the

same time. The process used by every ultrasonic sewing machine is

fast, simple and efficient. It can seal up to 80 meters per minute

without the need for threads nor needles.

It is indeed a flexible technology. Due to the adaptability of its

design, it is possible to mount the sewing machine on a workbench

or to install it into semi or fully automated systems.

Using an ultrasonic sewing machine brings forth a series of

advantages:

Instead of needles, thread, glues or other adhesives, ultrasonic sewing equipment uses a patented rotary system, coupled with high-frequency vibrations, to bond synthetic or blended materials containing up to 40 percent natural fibers.

Resembling a traditional sewing machine, the ultrasonic sewing machine channels the ultrasonic vibrations between a horn and rotating wheel, producing a localized heat buildup which causes the synthetic fibers to soften and fuse. This creates a strong molecular bond that’s impervious to moisture.