Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

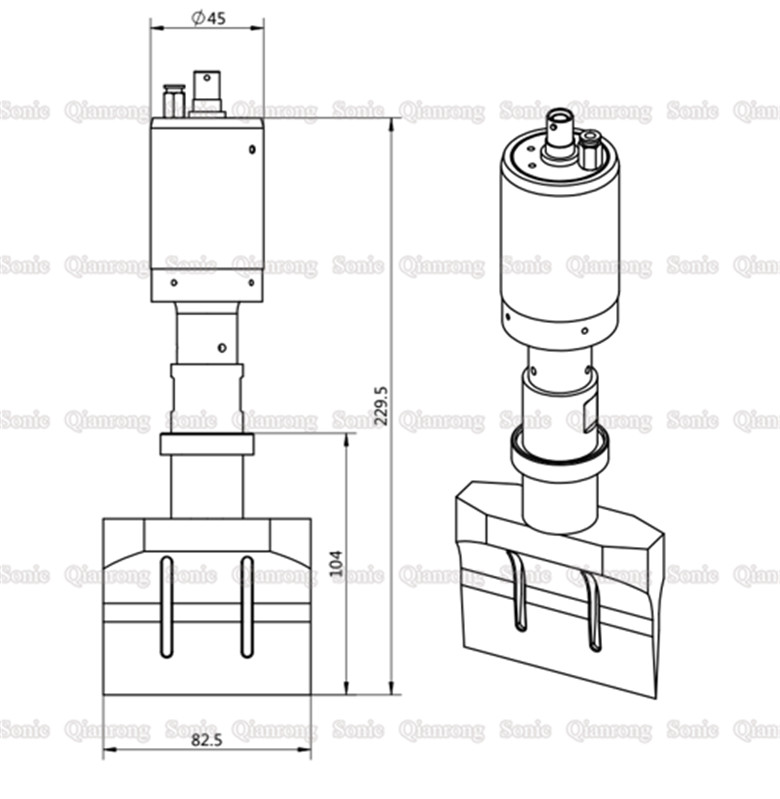

40Khz Ultrasonic Rubber Cutter with Titanium Blade Dual Use for Manual or Machine Loading

Description:

40K ultrasonic rubber cutting knife utilizes the energy of ultrasonic waves to melt the localized material of the material to be cut, so as to easily cut resin, rubber, non-woven fabric, film, various overlapping composite materials and food.

The main components of an ultrasonic cutting system include an ultrasonic generator (drive power), an ultrasonic transducer, a horn, a cutter (tool head), and various output lines and control lines. The ultrasonic drive power source converts the commercial power into a high-frequency high-voltage alternating current and outputs it to the ultrasonic transducer. An ultrasonic transducer is actually equivalent to an energy conversion device that converts input electrical energy into mechanical energy, ie, ultrasonic waves. Its manifestation is that the transducer moves back and forth in the longitudinal direction. The frequency of the telescopic motion is equivalent to the frequency of the high frequency alternating current supplied by the driving power source. The role of the horn is to fix the entire ultrasonic vibration system and to amplify the output amplitude of the transducer. The cutting blade (tool head) further enlarges the amplitude on the one hand and focuses the ultrasonic wave. On the other hand, the ultrasonic wave is output, and the ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by using a similar cutting edge of the cutting blade. Under the action of huge ultrasonic energy, the part softens and melts instantaneously, and the strength is greatly reduced. At this time, as long as a small cutting force is applied, the purpose of cutting the material can be achieved.

Specifications:

| Item No | QR-CR40Y |

| Power | 800W |

| Generator | Digital generator |

| Frequency | 40KHZ |

| Voltage | 220V or 110V |

| Cutter Dimension | 72*82.5*25.5mm |

| Weight of blade | 1.5kgs |

| Gross weight | 13Kgs |

Advantages and characteristics:

1. The incision is smooth and firm, the cutting edge is accurate, it will not be deformed, and it will not be warped, fluffed, drawn, or wrinkled;

2. High cutting precision and constant rubber compound;

3. The cutting surface has good finish and good bonding performance;

4. Fast, efficient and pollution-free;

5. Beautiful appearance, simple operation, no oscillation when cutting, quiet and easy to carry.