Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

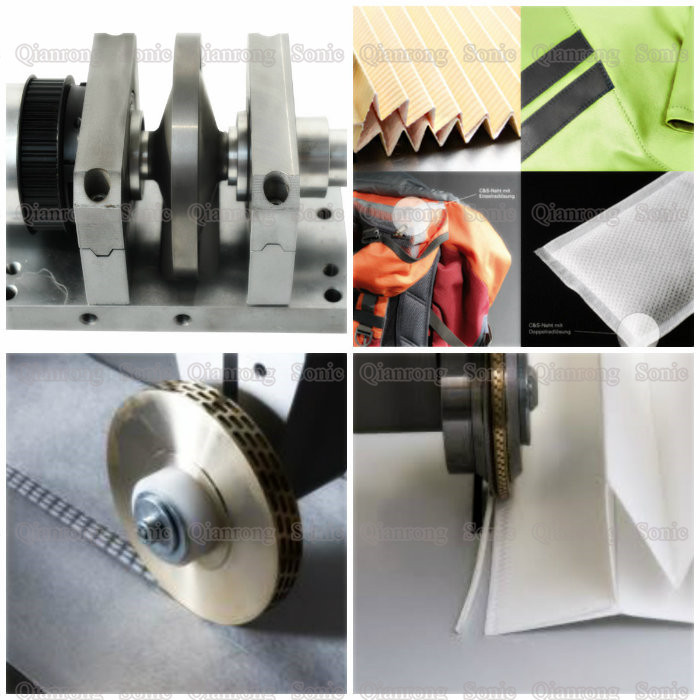

35K Ultrasonic Seamless Suturing System with Disc-shaped Welding Head and Dedicated CNC Power Supply

Description:

The ultrasonic seamless suturing system is composed of a 35K

ultrasonic transducer, a horn (fixed action), a disc-shaped welding

head and a dedicated CNC power supply. The ultrasonic numerical

control power source converts the commercial power into 35K

high-frequency high-voltage alternating current and supplies it to

the ultrasonic transducer. The ultrasonic transducer converts

electrical energy into mechanical energy (ultrasonic waves), and

the transducer generates amplitude when it is telescopically moved

in the longitudinal direction, and then transmits it to the

disc-shaped welding head through the horn. Thus, the disc-type

welding head is welded, equipped with a frame, a pressure roller

and an auxiliary structure and control part, which is a complete

ultrasonic cutting sewing machine.

Ultrasonic seamless suturing system can suture most thermoplastic

fabrics. Compared with ordinary needle stitching, ultrasonic

stitching has the characteristics of no needle thread, high

stitching strength, good sealing and fast sewing speed. And the

ultrasonic seamless suturing system also completely solves the

problem that the moving direction of the ultrasonic welding head is

inconsistent with the moving direction of the cloth, and the

problem of non-synchronization will replace the ordinary sewing

machine to a large extent.

Specifications:

| Item No | QR-S35D |

| Power | 1000W |

| Generator | Digital generator |

| Frequency | 35KHZ |

| Voltage | 220V or 110V |

| Width of welding wheel | 11.5mm |

| Matched Transducer | 3535-4D PZT4 |

| Generator size | 250*200*430mm |

Advantages:

1. High stability: When the ultrasonic is seamlessly stitched, the

rotation of the welding wheel and the pressure roller is completely

synchronized, and there is no difference in speed and angle, which

will not cause stretching, twisting or deformation of the cloth,

and the precision is extremely high. Thanks to the hot melt effect,

no needle thread is required, the product is more waterproof,

lighter in weight and easier to fold.

2. Welding and cutting synchronization: Ultrasonic seamless sewing

equipment is not only suitable for continuous sewing, but also for

cutting textiles while welding, and achieving automatic edge

sealing.

3. No heat radiation: When the ultrasonic is sutured, the energy

penetrates through the material layer for welding without heat

radiation. In the continuous stitching process, heat is not

transmitted to the product, which is particularly advantageous for

the packaging of the heat sensitive product.

4. Weldable seam control: The cloth is passed between the welding

wheel and the pressure roller, and the fabric is welded by

ultrasonic wave. The pressure roller can be changed to change the

weld size and embossing, which is more flexible and convenient.

5. Wide range of applications: All thermoplastic (softened and

softened) fabrics, special tapes and films can be welded using

ultrasonic seamless stitching equipment. The rollers are made of

hardened steel to extend the service life.

35K Ultrasonic Seamless Suturing System with Disc-shaped Welding

Head and Dedicated CNC Power Supply