Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

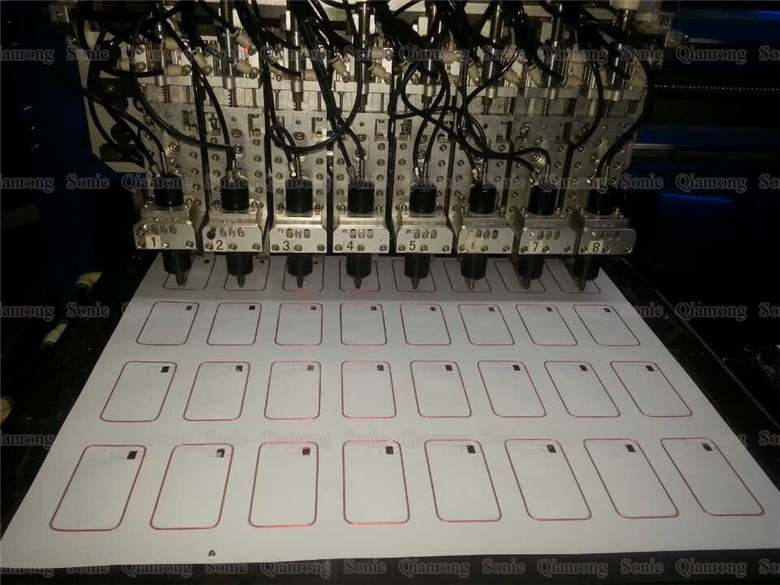

High Frequency 60Khz Ultrasonic Copper Wire Welding for IC Card

Principle:

Ultrasonic embedding device, also known as smart card antenna welding machine, smart card spot welding machine, smart card antenna implanting machine, etc., is a professional equipment for smart card embedding. It is applied to sheet welding positioning and antenna embedding. One of the important applications in the field of ID smart cards. Hangzhou Qianrong Automation Equipment Co., Ltd. is a national high-tech enterprise specializing in the manufacture and research of ultrasonic equipment. It has many years of experience in ultrasonic welding applications and can provide solutions for the buried welding of various ID smart cards.

Specifications:

| Item No | QR-W60A |

| Power | 100W |

| Generator | Digital generator |

| Frequency | 60KHZ |

| Voltage | 220V |

| Protective sleeve | φ25*110 |

| welding head | Aperture 0.3mmor 0.5mm |

| Gross weight | 5Kg |

| Work current | <1A |

| Cooling compressor air | >0.1MPa/unit |

Competitive Advantage:

1. Steady welding point, completely eradicate insufficient solder technically.

2. The size of welding spots is the same, equality line, good effect on uniformity.

3. The welding spot is small, wouldn’t increase the weight of the coil, easy to do lamination and encapsulation.

4. To leave out the immersion tin step before doing welding, save an operator.

5. After skilled in welding, much faster than the way to use searing iron to do weld.

6. On the process on manufactory, there is no waste gas, waste rubbish on pollution, runs in quiet and no noise.

7. To select the frequency 60KHz, one machine could drive 5-10 ultrasonic products, the speed to do welding is much faster.

8. Low power consumption, to save production cost for manufactory enterprise.

High Frequency 60Khz Ultrasonic Copper Wire Welding for IC Card