Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

High Frequency 40Khz 500w Ultrasonic Welding Transducer with Steel Booster

Description:

Ultrasonic vibrator is an energy conversion device, and its performance description and evaluation requires many parameters. The characteristic parameters of the transducer include resonance frequency, frequency bandwidth, electromechanical coupling coefficient, electroacoustic efficiency, mechanical quality factor, impedance characteristics, frequency characteristics, pointing Sex, emission and receiving sensitivity, etc. Ultrasonic vibrators for different applications have different performance parameters. For example, for an emissive transducer, the transducer is required to have large output power and high energy conversion efficiency; Transducers require a wide frequency band and high sensitivity and resolution. Therefore, in the specific design process of the ultrasonic vibrator, the relevant parameters of the transducer must be rationally designed according to the specific application.

Specifications:

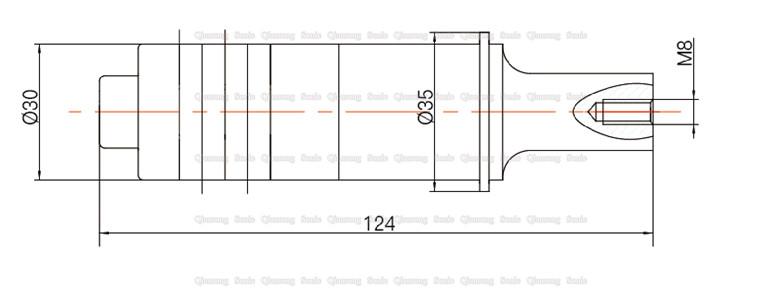

| Model | QR-3040-4BZ-BJ |

| Frequency | 40khz |

| Output power | 500 watt |

| Ceramic disc Diameter | 30mm |

| Qty of ceramic discs | 4pcs |

| Capacitance | 5.1-7.5nf |

| Application | Ultrasonic Plastic Welding machine |

Factors affecting ultrasonic welding:

Speaking of the weldability of thermoplastics, it is impossible to mention the requirements of ultrasonic bonding for various resins. The most important factors include polymer structure, melting temperature, flexibility (hardness), and chemical structure.

The non-crystalline polymer molecules are disordered in arrangement, with a significant temperature (Tg glass transition temperature) which gradually softens the material, melts and flows. Such resins are generally effective in transmitting supersonic vibrations and achieving good soldering over a wide range of pressures/amplitudes.

The semi-crystalline polymer molecules are arranged in order, with a distinct melting point (Tm melting temperature) and a re-freezing point. The solid crystalline polymer is elastic and absorbs some of the high frequency mechanical vibrations. Therefore, such polymers are not easy to transmit ultrasonic vibration energy to the pressing surface, which requires a higher amplitude. High energy (high heat of fusion) is required to break the semi-crystalline structure and change the material from a crystalline state to a viscous state, which also determines the apparent melting point of such materials. Once the molten material leaves the heat source, A decrease in temperature causes rapid solidification of the material. Therefore, the particularity of such materials (eg high amplitude, good design of joints, effective contact with ultrasonic fixtures, and excellent working equipment) must be considered in order to achieve the success of ultrasonic welding.

The process of bonding monomers together is referred to as "polymerization." Polymers can be broadly classified into two broad categories: thermoplastic and thermoset. After the thermoplastic material is thermoformed, it can be softened and molded again. The base undergoes only a change in state - this property determines the adaptability of the thermoplastic material to ultrasonic compression. Thermosetting materials are produced by irreversible chemical reactions. Reheating or pressurization does not soften the formed thermosetting products. Therefore, thermosetting materials have traditionally been considered to be unsuitable for ultrasonic waves.

The higher the melting point of the polymer, the more ultrasonic energy it needs to weld.

The hardness of the material is very effective in its ability to effectively transmit supersonic vibration. In general, the harder the ultrasonic power source material, the stronger its conductivity.

The welding head vibrating at the ultrasonic frequency rubs the heat at a predetermined time and pressure to fuse the plastic joints to each other, which is firm and convenient.

High Frequency 40Khz 500w Ultrasonic Welding Transducer with Steel Booster