Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

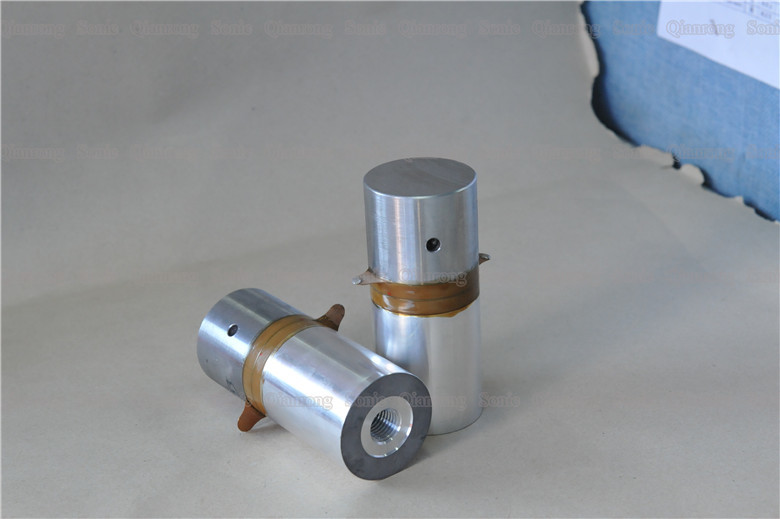

20Khz 800w Ultrasonic Transducer with Imported Piezoelectric Conversion Ceramics

Description:

The welding kit/sonic energy system welding kit provides ultrasonic mechanical vibration, generally consisting of three parts: the transducer, the horn and the welding head, and is fixed on the welding press in the middle of the horn. The soldering kit is a resonator that is somewhat similar to a tuning fork. The resonant frequency of the soldering kit must closely match the frequency of the electrical signal from the generator (with a difference of less than 30 Hz).

Specifications:

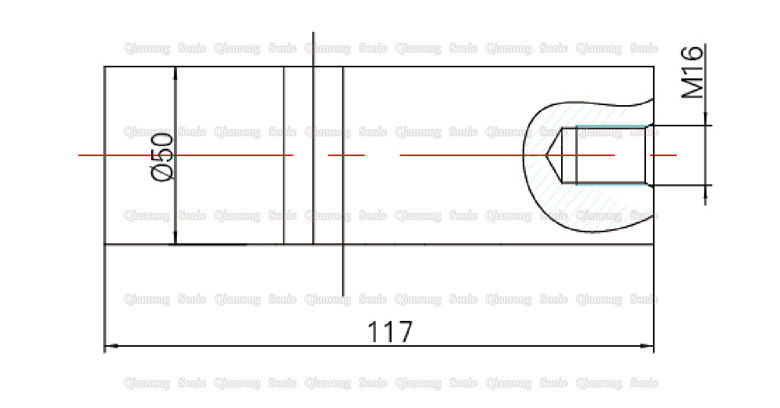

| Model | QR-5020-2BL |

| Frequency | 20khz |

| Output power | 800 watt |

| Joint bolt | M16 |

| Ceramic disc Diameter | 50mm |

| Qty of ceramic discs | 2pcs |

| Capacitance | 5.5-6.2nf |

| Amplitude | 10 um |

| Application | Plastic welding machine |

Functions of Horn:

The weld head is the part of the weld kit that supplies energy to the part to be welded. Like the horn, the horn is also a tuning device that is mechanically amplified in most applications. The length of the horn must be an integer multiple of the half or half wavelength of the ultrasonic in its material. This ensures that the end of the horn has sufficient amplitude to achieve soldering. The amplitude is generally 30-120 um. The part to be welded and the joint design determine the size and style of the weld head. The shape of the horn is critical because the stress caused by the axial expansion and contraction of the horn can cause cracking at high amplitudes. In some applications, the horn is machined with a plurality of axial slots. This is to ensure that the maximum amplitude is in the longitudinal direction. The end of the horn transfers ultrasonic energy to the part to be welded. The ends should be specifically designed to match the parts to ensure maximum energy transfer between the weld head and the part. Usually the end of the weld head is made into a profile that matches the contour of the part. About 75% of the horns are made of titanium, about 15% are made of aluminum, and the other horns are made of hardened steel of H RC54-56. Titanium is light, suitable in hardness, good in toughness and excellent in acoustic performance. It is often used in small welding heads. Titanium can also be coated with hard alloys for high wear. However, it is expensive and difficult to machine. Lightweight aluminum, easy to process, good acoustic performance and low cost, it is used to make large welding heads and prototype welding heads for large parts welding or welding heads with complex machining. Aluminum welding heads are not suitable for long-term production applications due to their low surface hardness, easy wear and poor fatigue properties, and are often used in small batch applications. To prevent indentation and reduce wear, aluminum must be plated with nickel or chromium. Steel weld heads are required when impact or wear resistance and welding of filled plastic or embedded metal inserts are required. The steel weld head has low fatigue strength and is only used in low amplitude applications. Complex parts, special or large parts usually require a composite horn (female horn), where the base horn is made of aluminum, titanium or steel secondary horns are connected to the base horn and guide energy

20Khz 800w Ultrasonic Transducer with Imported Piezoelectric Conversion Ceramics