Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

Enhancing Production Rate and Good Quality by 35Khz Ultrasonic

Sealing Technology

Description:

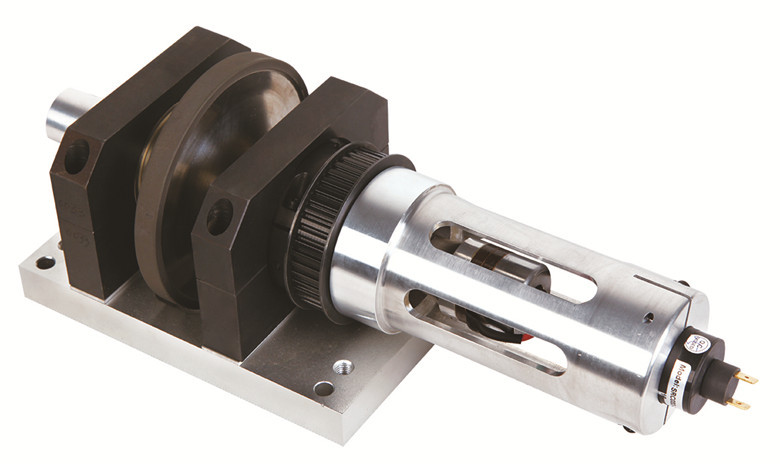

The ultrasonic system is mainly composed of ultrasonic generator

and ultrasonic transducer. The ultrasonic transducer is a sandwich

transducer made of lead zirconate titanate piezoelectric ceramic

material. The piezoelectric ceramic material has an electric field

effect. Under the phenomenon of dimensional change, the transducer

generates mechanical vibration under the action of an alternating

electric field.

Ultrasonic system normal condition: The normal vibration group

(transducer + horn) has a current of 0.3A~0.8A and an amplitude of

1%~10%.

Specifications:

| Item No | QR-S35ND |

| Power | 1000W |

| Generator | Digital generator |

| Frequency | 35KHZ |

| Voltage | 220V or 110V |

| Width of welding wheel | 11.5mm |

| Matched Transducer | 3535-4D PZT4 |

| Generator size | 250*200*430mm |

Device installation:

1. Disassemble the package, check the surface and parts of the equipment for signs of damage, check whether the screws are loose, whether the electrical connectors are locked, and whether the accessories are complete.

2. Ultrasonic lace machine equipment should be placed on a flat hard ground, requiring the lace machine to be at least 0.5 meters away from the heat source, and to ensure that the lace machine has at least 1 meter before and after, and at least 0.5 meters of space for operation.

3. Check the voltage requirements on the back of the vibration box and ensure that the system is well grounded.

4. Connect the device to the power supply and air supply. Be sure to turn off the power switch first. Pay attention to the voltage requirements of this unit: AC220V, 50-60Hz

5. The air line is connected to a clean, non-lubricated compressed air source with a rated working pressure of 0.6 MPa.

Enhancing Production Rate and Good Quality by 35Khz Ultrasonic

Sealing Technology