Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

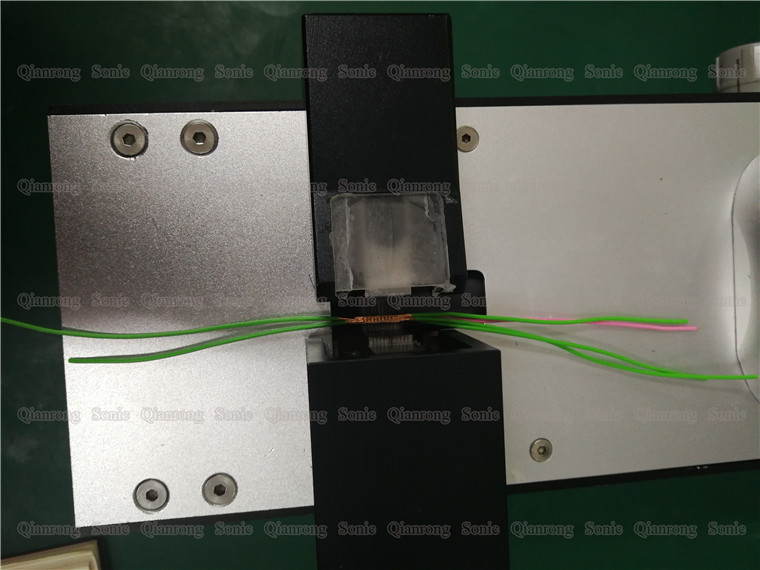

20khz 3000w Ultrasonic Metal Welder 0.5-20mm2 Apply In Wire Copper

Description:

Copper wire harness pressure square ultrasonic welding machine uses

copper wire square welding machine equipment to use ultrasonic

principle for the pressure line of automobile wire harness welding

machine, Qianrong Automation Equipment Co., Ltd. specializes in

producing 0.75mm2, 1.0, 1.5, 2.0, 2.5mm2, 4mm2 6mm2 loose copper

wire is formed by square molding. The welding head transmits the

received vibration energy to the joint of the workpiece to be

welded. In this region, the vibration energy is converted into heat

energy by friction, and the atomic chain of the metal surface is

broken, and the size of the reassembled wire harness compact can be

adjusted according to product requirements.

Parameters:

| Item No | QR-X2020A | QR-X2030A | QR-X2040A |

| Power | 2000W | 3000W | 4000W |

| Welding Area | 0.5-16mm2 | 0.5-20mm2 | 1-30mm2 |

| Air Pressure | 0.05-0.9MPa | 0.05-0.9MPa | 0.05-0.9MPa |

| Frequency | 20KHZ | 20KHZ | 20KHZ |

| Voltage | 220V | 220V | 220V |

| Weight of horn | 18KG | 22KG | 28KG |

| Dimension of Horn | 530*210*230mm | 550*220*240mm | 550*250*240mm |

| Generator Size | 540*380*150mm | 540*380*150mm | 540*380*150mm |

Advantaged of Copper wire square welding machine equipment welding:

(1) The two welded objects overlap, and are joined into a solid

form by ultrasonic vibration and pressure bonding, the joining time

is short, and the joint portion does not produce a cast structure

(rough surface) defect;

(2) Compared with ultrasonic welding and electric resistance

welding, the mold has a long service life, less mold repairing and

replacement time, and is easy to realize automation;

(3) Ultrasonic welding can be performed between different metals of

the same metal, which consumes much less energy than electrical

welding;

(4) Compared with other pressure welding, ultrasonic welding

requires less pressure and the deformation amount is below 10%,

while the workpiece deformation of cold pressure welding is

40%-90%;

Adopting advanced ultrasonic welding technology, the quality of

wire harness terminal welding products is high; the wire harness

welding equipment for copper wire square welding machine equipment

is the fusion of metal molecular layer, suitable for body welding,

without destroying the original workpiece; low requirements on

welding metal surface, oxidation or Electroplating can be welded;

welding without sparks, resistance and current is very small,

suitable for sealing welding of precision parts, drugs and

explosive materials; low temperature welding, very thin metal is

welded to thick metal without causing damage to thin metal.

20khz 3000w Ultrasonic Metal Welder 0.5-20mm2 Apply In Wire Copper