Nanjing Zhitian Mechanical And Electrical Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

Looking for a reliable OEM manufacturer of twin screw extruder

parts? Look no further than Zhitian. As a leading player in the

industry, we specialize in providing the most professional OEM

solutions for twin-screw extruder screw elements. With our

extensive range of sizes, ranging from 15mm to 350mm and beyond, we

have the perfect fit for your specific requirements.

At Zhitian, we are committed to pushing the boundaries of

construction materials and continuously improving our manufacturing

process. Our dedicated team places a high priority on delivering

exceptional quality while maintaining low costs and competitive

lead times. When it comes to critical replacement screw barrels,

you won't find a better source than Zhitian.

With our unwavering commitment to innovation in materials and

relentless enhancement of our manufacturing process, we have placed

paramount importance on delivering superior results. This

dedication, combined with our steadfast focus on cost-efficiency

and unmatched turnaround times, positions us as the ultimate

destination for all your critical replacement screw barrel needs.

We can satisfy your different material needs:

According to appearance design,Closed Barrel,Feeder Barrel,Side Feeder Barrel,Venting Barrel,Combi

Barrel.

According to the liner,With liner barrel,Without liner barrel.

According to Materical,

-For wear application:C liner;Cr26;Cr12MoV;W6Mo5Cr4V2;

-For corrosion application:38CrMoAla;Hac alloy;

-For wear and corrosion application:Nickel based

alloy;316L,304;WR13,SAM26etc.

Through the understanding of customers,recommend the most valuable

material.

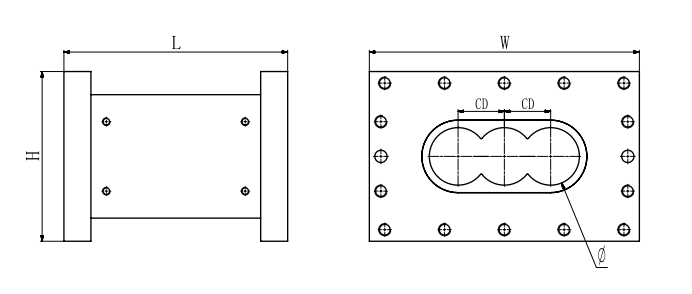

Barrel Dimensions

| ||||

| NO. | Model | L*W*H(MM) | Hole Diameter/Φ(MM) | Center Distance/D(MM) |

| 1 | 75 | 290*350*220 | Φ74.6 | 60 |

Cr26 Overall Liner

Cr26 is based on ultra high chromium alloy powder of high

wear-resisting,corrosion resistance alloy,with special heat

treatment process of the product.Through further refine crystal

groups,large amount of various solid carbide distribution and

uniform,wear resistance and comprehensive mechanical performance is

geat optimization,is a new generation of high-performance twin

screw extrusion machine accessories and preferred products.

| Cr26 Chemical Composition | ||||||||||

| C | Cr | V | Mo | Si | Mn | Ni | W | Cu | Ti | |

| W-% | 2.7 | >25 | 1.1 | 1.1 | 0.5 | 0.5 | 0.5-0.8 | 1-1.2 | 1-1.2 | 0.5 |

Production Process

| |

|  |

| |

|  |

| |

Packaging

|  |  |

| ||

FAQ

How long does it take to get my products since I paid for them?

---According to yout order quantity,we will give you a reasonable

delivery date.

Can I get the warranty of one year for free?

---If you need the warranty,you should pay for it.If not,do not

worry ,we have confidence in our products.

How is your after-sale service?

---You will get our help in time as long as you find something

wrong about our produces.Believe us,you deserve the best.

How long will your product last?

---I am sorry that I can not accurately answer your question,which

is quite different from your operation time,materials and

materials.