Nanjing Zhitian Mechanical And Electrical Co., Ltd. |

|

Verified Suppliers

|

|

Quick Details

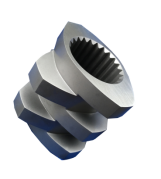

Product Name:Wear And Corrosion Resistance Screws And Barrels Nickel Alloy

Material For Extrusion Machine Twin Screw Extruder

Material: Nickel based alloy

Color: Metal

Packaging: Wooden Box

Lead Time: 30-60 days

At Zhitian, we are passionate about delivering innovative solutions that go beyond industry standards. We pride ourselves on customizing high-quality products to meet your specific needs. Work with us to experience first-hand the transformative impact our wear and corrosion resistant material solutions can have on extrusion processes.

Screw Barrel Specifications Table

| ||||

| NO. | Model | L*W*H(MM) | Hole Diameter/Φ(MM) | Center Distance/D(MM) |

| 1 | 20 | 132*115*105 | Φ23 | 18.4 |

| 2 | 30 | 120*135*115 | Φ30.6 | 26 |

| 3 | 35 | 140*140*120 | Φ36 | 30 |

| 4 | 36 | 150*160*140 | Φ36 | 30 |

| 5 | 40 | 160*175*145 | Φ41.6 | 34.5 |

| 6 | 50 | 190*190*150 | Φ51 | 42 |

| 7 | 52 | 210*200*155 | Φ52 | 43 |

| 8 | 53 | 220*210*160 | Φ53.3 | 48 |

| 9 | 58 | 240*220*175 | Φ58 | 48 |

| 10 | 60 | 240*210*170 | Φ60 | 52 |

| 11 | 65 | 240*210*170 | Φ63 | 52 |

| 12 | 75 | 290*260*200 | Φ71.8 | 60 |

| 13 | 85 | 320*280*215 | Φ81.9 | 67.8 |

| 14 | 92 | 360*310*240 | Φ92 | 78 |

| 15 | 95 | 360*310*240 | Φ94 | 78 |

| 16 | 110 | 420*330*240 | Φ109 | 91.5 |

| 17 | 125 | 500*390*290 | Φ125 | 98 |

| 18 | 135 | 520*440*340 | Φ134 | 110 |

We can satisfy your different material needs:

According to appearance design,

Covey Screw Segment,Mixing Screw Segment,Kneading Block&disk,Transition Screw Element,Deep groave Transfer Element,Screw Element for side feeder,1/2/3-flighted Screw Element,OEM Special Screw Element.

|  |  |

| 1-flighted | 2-flighted | 3-flighted |

|  |  |

| KB 30° | KB 45° | KB 60° |

|  |  |

| KB 90° | SK | DISK |

According to Screw Barrel Materical

-For wear application:

Tool Steel:W6Mo5Cr4V2

PM-HIP material:WR5,WR13,WR14,CPM10V,CPM9V.

-For corrosion application:

38CrMoAla

PM-HIP material:WR4,WR13,WR14,CPM10V,CPM9V.

-For wear and corrosion application:

PM-HIP material:WR13,WR14,CPM10V,CPM9V.

-Other materials:

Stainless Steel:316L,440C etc.

Through the understanding of customers,recommend the most valuable material.

Tool Steel

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

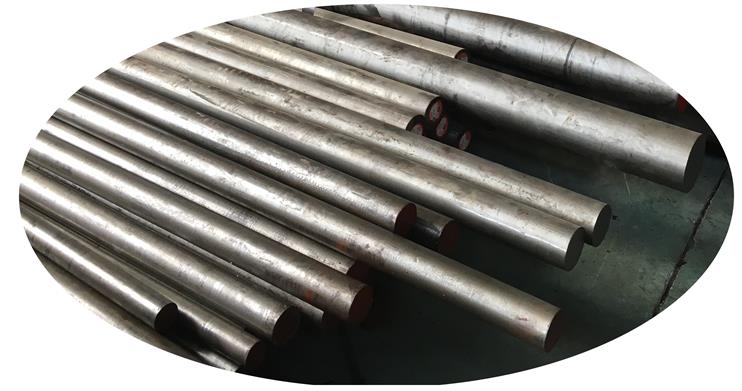

| NO.1

Workblank

Select high-quality raw materials

|

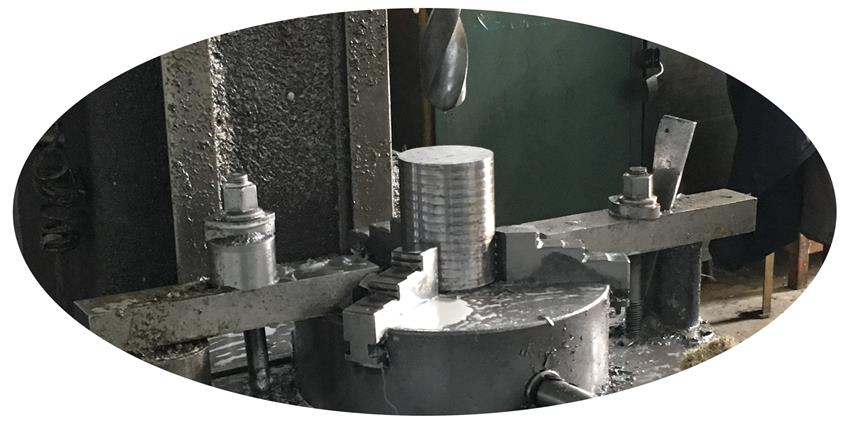

NO.2

Piecewise

|  |

| NO.3

Hit bottom hole

|

NO.4

Machining thread

|  |

| NO.5

Finish machining thread

|

NO.6

Threading grinding

|  |

|  |  |

| ||

FAQ

Are your quotations all FOB?

---Yes

How long does it take to get my products since I paid for them?

---According to yout order quantity,we will give you a reasonable

delivery date.

Can I get the warranty of one year for free?

---If you need the warranty,you should pay for it.If not,do not

worry ,we have confidence in our products.

How is your after-sale service?

---You will get our help in time as long as you find something

wrong about our produces.Believe us,you deserve the best.