Sichuan Advance technology Co.,Ltd |

|

Verified Suppliers

|

|

PC twin screw extruder line, output 3300Kg/h,HPL96 PC granulator

Introduction

We have accumulated a lot of successful experiences in large-scale chemical projects and transformation projects and service of imported petrochemical equipment. We can provide you all technicals and process know how necessary for petrochemical granule production start-up

reducing time to market to a minimum.

Application:PC,ABS, PP,PPR,POM

Techincal data

| Screw diameter | 95mm |

| L/D | 36:1 |

| Screw speed | 60~600rpm |

| Drive motor power | 670Kw |

| Torque per shaft | 5332N.m |

| Output | 3300KG/H |

| T/A3(Nm/cm3) | 11.5 |

| D/d | 1.56 |

| Heating power | 128KW |

| Output | High speed tool steel |

| Liner of barrel | Powder metallurgy steel |

| Screw shaft | Finland material HIP-WR15E |

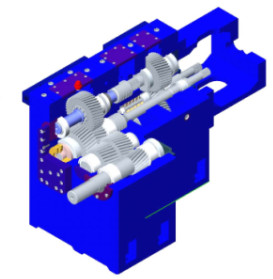

| Gearbox | Bilateral symmetry gear drive system realize high torque output |

| Machine frame | Whole steel plate welded basic frame |

| Screen exchanger | Double-piston continuous screen changer with 2 working positions |

| Pelletizer | Underwater pelletizer group |

Our advantages

1. High output

The output is 1-2 times larger than the same size extruder from other lower torque twin screw extruders.

The biggest extruder can output up to 12T/h per set.

2. Energy-saving

For the same output , our small size extruder can replace the big size of other extruder, such as our HPL51 has more output than other 65 extruder , smaller extruder, less energy consumption,less material consumption, smaller production areas.

And we use heat rod instead of cast copper heater, which can save 15%-20% energy.

3. Advanced design

High torque: carrying capacity factor of gearbox up to 15Nm/cm3;

High speed: max. 1800rpm/m;

4. Long service life

bearings on output shaft 2 without load, which greatly extended the service life of the bearings on the weak axis , gearbox life can reach 72000 hours (10 years);

5. Custom made design

Wide D/d choice:1.33~2.0;

Custom made clearance: minimum clearance can be 0.15mm;

About us

We are dedicate to develop, design, and manufacture co-rotation, counter-rotation parallel twin-screw extruder production line.Our extruders have the advantages of “high torque, high efficiency, low energy-consumption, high price/performance ratio, long service life ” (designed service life of gearbox as long as 72000 hrs). We keep the same step with the most advanced extruder manufaturers in the world.

We can supply :Twin screw extruder production line;

High torque gearbox;Automatic long fiber reinforced thermoplastic composites (LFT - D) production line;Counter-rotation parallel twin screw extruder;Differential concentration mixer;

Repairing and machining large parts; Design, machine all of screw elements on Japan and Germany extruders.

Parts and advantages

| Transmission gearbox |  | The most advanced structure: bilateral symmetry gear drive system; it’s the same with the gearbox of German Flanders, Austria EssenBas.Now, the first-line extruder manufacturers in the world, such as Corperion,Berstorff, Leistritz, Toshiba, JSW are using the transmission structure; servcie life of the gearbox≥72000hrs. |

| Screw element |  | Various kinds of function elements, mixing and dispersing elements developed by ourselves can provie flexible production for kinds of materials and production process. Optional material: W6Cr5Mo4V2, Ni-based alloy, HIP alloy,Co-based alloy. |

| Barrel |  | Barrels are equipped with integrated wear-resistant alloy steel liner, which has the same composition and wearing feacture with W&P .Our mirror polishing seamless barrels, surface finish Ra0.2, verticality between barrels inner hole≤0.015mm;linearity of ten assembled barrels≤0.05mm; Optional material: W6Cr5Mo4V2, Nitriding steel, Tool steel, Ni-based alloy, HIP alloy,Co-based alloy. |

| Torque limiter |  | Steel ball type safety clutch + torque limiter Made in Germany have the characteristics of accurate torque protection, high repeatability and quick reset. |