Shenzhen Yideyi Technology Limited Company |

|

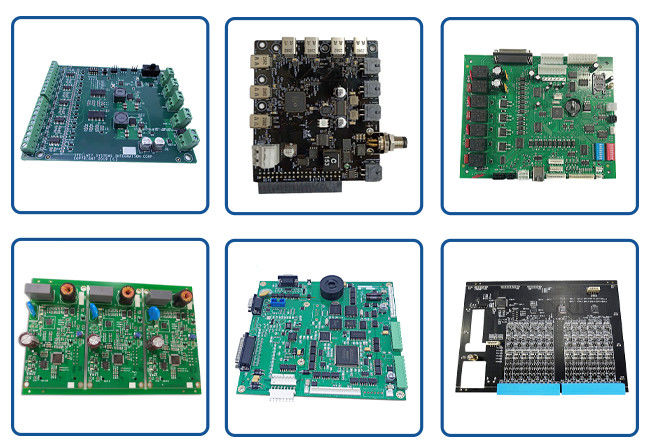

Monitor Sensor SMT THT Manufacturing Double Sided PCB Assembly

Capabilities

Our Capabilities of Double Sided PCB Assembly

| Total Pad Size | Standard | Advanced |

| Capture Pad | Drill + 0.008 | Drill + 0.006 |

| Landing Pad | Drill + 0.008 | Drill + 0.006 |

| BC Mechanical Drill (Type III) | 0.008 | 0.006 |

| Laser Drill Size | 0.004-0.010 | 0.0025 |

| Material Thickness | 0.0035 | 0.0025 |

| Stacked Via | Yes | Yes |

| Type I Capabilities single & Double Deep | Yes | Yes |

| Type II Capabilities Buried Vias with Microvias | Yes | Yes |

| Type III Capabilities | Yes | Yes |

| Copper Filled Microvia | Yes | Yes |

| Smallest Copper Filled Microvia | 0.004 | 0.0025 |

| Copper Filled Microvia Aspect Ratio | 0.75:1 | 1:1 |

| Smallest Laser Microvia Hole Size | 0.004 | 0.0025 |

Laser Via Aspect Ratio (Depth:Di ameter) | 0.75:1 | 1:1 |

Benefits of double sided PCBs

We mentioned earlier that double sided PCBs are more useful in creating higher technology electronics because they have two-sided traces instead of one. This provides a lot of benefits for those using double sided PCB in their industry.

Perhaps one of the most important benefits of using double sided PCB is that they help reduce overall cost. In addition to having a relatively lower price compared to single sided PCB, double sided PCB also provides more flexibility for designers while simultaneously reducing the size of the circuit board itself. Smaller board sizes can also help further reduce cost, which is another plus.

PCB double sided is also associated with increased circuit density and an intermediate level of circuit complexity. Increased circuit density often helps contribute to lower cost as well, as compared to more complex, multilayer PCBs.

Double sided PCBs are often a better choice than single sided PCBs because of their complexity. If your circuit board is more densely populated to connect a lot of components, it’s better to have some components connected to the bottom side rather than all on one side.

If you’re unable to change the size of the board size, and you need to route Vcc and GND on a single board, picking a two-layer board and routing Vcc and GND to the bottom layer will help you out.

If you intend to sink or source current, choosing double sided PCB will most likely make more sense because of the top and bottom layer. You can use the bottom layer as a ground copper pour. For all of these reasons, double sided PCB is often the ideal choice for most professionals working in the technology fields because it’s much easier to use and is much more flexible when you do use it.

Shenzhen Yideyi Technology Co., Ltd provide turnkey solution including PCB fabrication, SMT, plastic injection & metal,final assembly, testing and other value-added service

FAQ:

Q1. How can we ensure our information should not let third party to

see our design?

We are willing to sign NDA effect by customer side local law and

promising to keep customers date in high confidential level in all

projects.

Q2.What is your standard turnatound time for PCB Assembly ?

Our standard turnaround time for PCB Assembly is 3 weeks.

Q3. Do you offer first article inspection ?

Yes, basis client requirements, we are well equipped to offer first

article inspection.

Q4.Do you offer quick turn PCB Assembly ?

Yes, we offer 24 hours quick turn PCB Assembled Solution without

sacrifice the quality of the PCB Board.

Q5. Do you offer IPC 610 or J-STD Quality inspections ?

Absolutely, we offer these inspections as per client requirements.

Q6. How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the

function test.Before that, our inspectors will use microscope and

X-ray to check the IC footwelding or bad solder etc.

Q7. What are the main products of your PCB/PCBA service?

Automotive, medical, Industrial control, Internet of Things, Smart home, military, Aerospace.

Q8. What is the PCB Assembly cost ?

The cost is based on a number of factors including the types of PCB

parts, order quantity and more. Once you reach out to us with your

bespoke requirements, we will revert with a custom quote