JWE CARBIDE CO., LTD. |

|

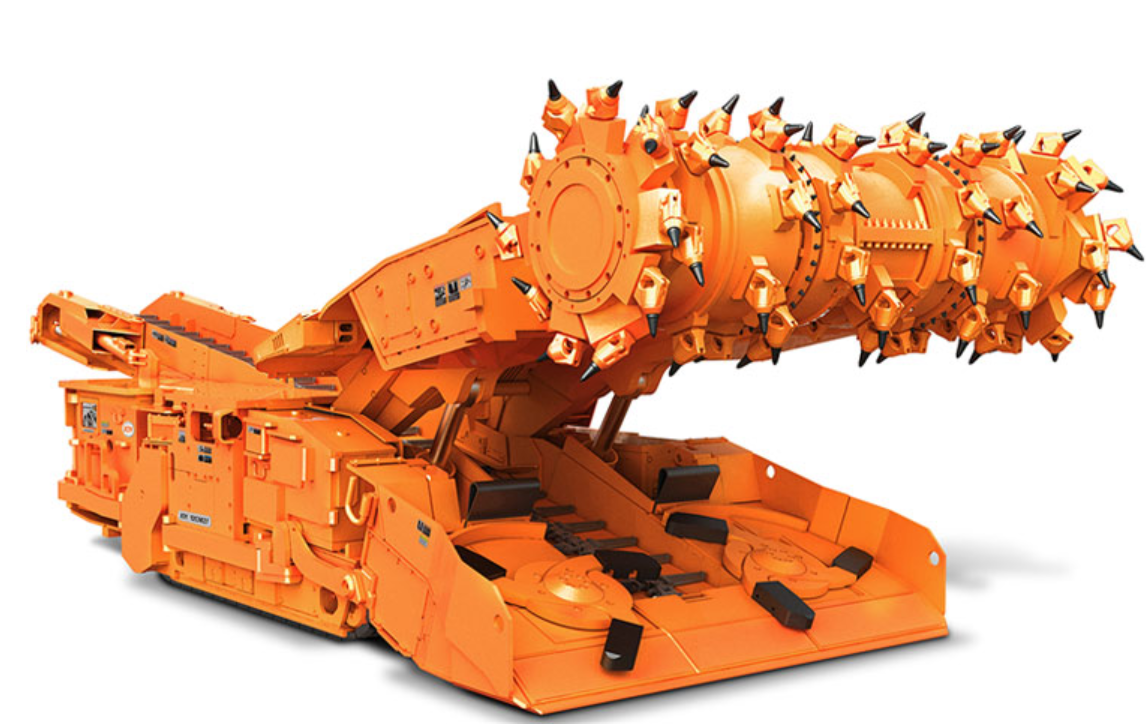

Product Description:

The M8425R series is our products specialized to medium to hard coal formation or condition. The shanks size is internationally accepted, but we developed several types divided by different carbide button dimensions. And M8425R -16, M8425R -22, M8425R -25 are most welcomed by our customer.

This kind of picks have hardfacing protection layer, which provides the maximum wear resistance to the carbide and alloy steel body. The retainer is easy to go design ensures an effective change on site. The parabolic type of carbide buttons have a better toughness and wear resistance.

All these Bits are made by high quality carbide buttons sintered with Stark Tungsten Powder and Alloy Steel cold extruded by automobile part processing technology.

Induction brazing is used in the product line of soldering process to bind these two kinds of metals bound under precious temperature control to assure the connection firmly and fully.

Product Demonstration:

Parabolic Carbide Buttons prevent thermal cracks from long time working under tough conditions and have good impact resistance under excavation conditions companied by coal gangue.

Slim body shape keeps the effective penetration with lower cost per ton of excavated material.

The cold forge process assures the body of the bit an integral flow of the steel, preventing any breakage during sudden impact with hard formations and conditions.

The sharper carbide buttons make each cutting effective and quick. This is very competitive in soft to medium hardness formation and minerals. And hardfacing is available as well, pertaining to the requirement of the customers.

Application:

All the bits of this series are suited for drilling, mining, tunnelling, trenching, etc in construction, surface and underground mining industries.

All drum cutter with standard block size is compatible. Trenchers, roadheaders, continuous miners, longwall miners, and highwall niners are the major equipment in line with the H35R4275A round shank bits.

Most international equipment brands are compatible as below:

1. longitudinal cutting system, continuous miner:

2. transverse cutting system, longwall shearer:

3. longitudinal cutting system, road header:

4. surface cutting system, trenchers:

Advantages:

The M8425R series are effective for coal mining, suitable for most of the shearer machines produced by Sany, XCMG, N.TRAFFIC, etc.

Its parabolic carbide buttons made of medium grain size of tungsten carbide and cobalt powders, making it has a good cutter rates and better thermal stability, and the hardfacing makes it an obvious advantage compared with normal bits without protection layers. We also supply OEM service according to specified need of customers.

Package & Shipping:

All the bits will be dipped into anti-rust oil and neatly packed into plastic boxes, then delivered on crates.

Colourized boxes make bits classification easily and shroten the sourcing time while teeth replacement on sites.

10 pieces in each box, ensure mobilization on site or confined spaces.

Q&A:

1. What kind of Terms of Payment do you accept:

T/T, Western Union or L/C at sight.

2. How long will you make a delivery after order placed:

Based on order quantity, normally it takes 25 days for production.

Only 2 or 3 days if we have stock on your request size.

3. Do you deliver product to place of xxx, and how:

Sample order: we suggest Courier express like DHL/UPS/TNT/FedEx by

air.

Bulk order: we suggest by sea.

4. Quality Control:

We have our own experienced QC.

There will be strict inspection and testing for every order before

shipment.

5. After Services:

1. Our sales team will respond to your question within 24 hours

(Holidays Excluded).

2. Technical Support will be available in any time.