JWE CARBIDE CO., LTD. |

|

Cemented Carbide Tips for Surgical Needle Holder, Medical Needle Holder TC Inserts

1.100%virgin material

2.types&sizes available

3.factory produce

Surgical Needleholders are high quality and available in a range to suit your operating need. Needle holders can be used for various surgical procedures.

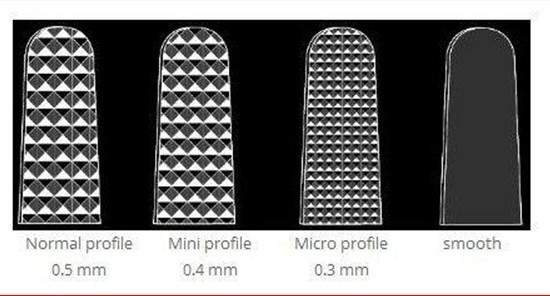

Profile of Tungsten Carbide Tip with teeth K10/K20 for surgical instruments

Regular: 0.5mm for use with sutures up to size 4-0.

Fine: 0.4mm for delicate needles and suture sizes 5-0 and 6-0.

Extra Fine: 0.3mm for use with microneedles and sutures up to size

10-0.

Smooth: For delicate needles and suture sizes 7-0 and 10-0.

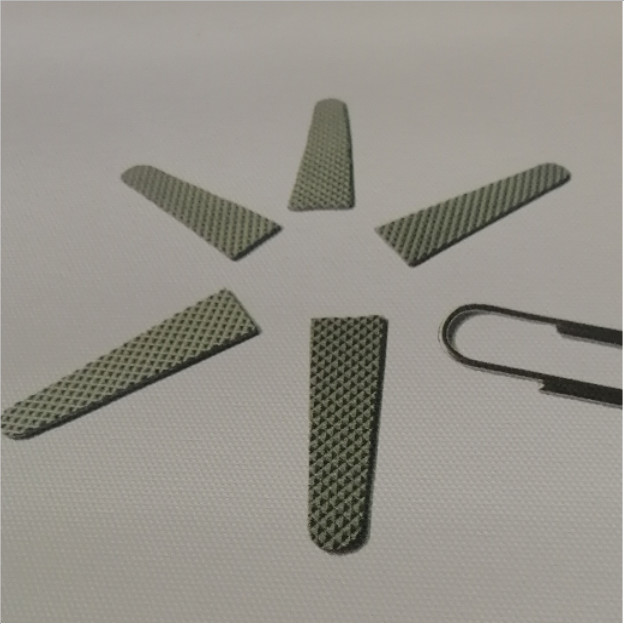

Detail pictures:

Performance chart:

| Grade | Cobalt content | Binder | WC particle /grain size | Density | Hardness | Coercive force Coercivity HC | Transverse Rupture Strength Flexural strength | ||

| (wt%) | (%) | (μm) | (g/cm3) | HRA | HV10 | HV30 | (KA/m) | (MPa) or (N/mm2) | |

| JK09 | 10.6-12.0 | 12 | 2.4 | 14.30 | 87.30 | 1100 | 5.0-8.0 | 2900 | |

| JK10.2 | 5.2-6.0 | 6 | 2.0 | 14.95 | 90.00 | 1350 | 11.2-13.0 | 2800 | |

| JK10.2T | 5.4-6.0 | 6 | 2.0 | 14.95 | 90.30 | 1380 | 11.2-13.2 | 3000 | |

| JK20.2 | 7.0-7.8 | 7.8 | 2.0 | 14.78 | 89.50 | 1300 | 9.2-11.3 | 3000 | |

| JK10.4 | 5.0-6.0 | 6 | 4.0 | 14.94 | 87.30 | 1100 | 5.3-6.5 | 2400 | |

| JK20.4 | 6.8-8.0 | 8 | 4.0 | 14.70 | 86.70 | 1050 | 4.3-5.5 | 2500 | |

| JK30.4 | 8.6-10.0 | 10 | 4.0 | 14.53 | 86.30 | 1010 | 4.0-5.0 | 2600 | |

| STK3050 | 8.6-10.0 | 10 | 5.0 | 14.53 | 86.30 | 1010 | 4.0-5.0 | 2650 | |

| YL2 | 7.0-8.2 | 8.2 | ≤1.0 | 14.75 | 91.50 | 1530 | 17.0-19.0 | 3000 | |

| YL3 | 6.8-8.2 | 8.2 | ≤1.0 | 14.70 | 91.50 | 1530 | 17.0-20.0 | 2800 | |

| YL10 | 8.5-10.0 | 10 | 1.2 | 14.48 | 90.50 | 1410 | 12.5-15.5 | 3100 | |

| YG6 | 14.85 | 90.00 | 2000 | ||||||

| YG8E | 7.0-8.2 | 8.3 | 1.6 | 14.60 | 89.80 | 1330 | 10.0-14.0 | 2600 | |

Production and test:

1)Carbide Buttons will start to prepare the powder as per the customer’s

requirement with our wet-grinding machine

2) Before mass production, we need to do a trial pressing and sintering, and we check the

appearances and the sizes of the samples with a micrometer to

ensure that the requirements of the drawings can be met before

batch production

3) Bulk production, press the raw materials to shape blanks, and

carbide tips must be passed by semi-finished inspection.

4) sinter blanks to finish (HIP) and finished products inspection

to ensure the best quality and production capacity.