Zhuzhou Xinpin Cemented Carbide Co.,Ltd |

|

double flute tungsten carbide rotary file color coating carbide burr for high speed deburring work piece

Shape of carbide burrs:

1.Cylindrical (Plain End)-Shape A;

2.Cylindrical (End Cut)_Shape B;

3.Cylindrical ( Ball Nose,Radius End)-Shape C;

4.Ball-Shape D;

5.Oval-Shape E;

6.Arch Ball Nose (Radius End)-Shape F;

7.Arch Pointed Nose(Pointed Ends)-Shape G;

8.Flame-Shape H;

9. 60°Cone-Shape J;

10.90°Cone-Shape K;

11. Conical Round Nose(Radius End)-Shape L;

12. Conical Pointed Nose -Shape M;

13.Inverted Cone-Shape N;

Company Introduction

Zhuzhou Xinpin Carbide Co.,Ltd. is a professional manufacturer of

high quality tungsten carbide for wood working industry. Our team

consists of engineers with over 20 year's experience of

production,technology, and research as well as marketing.

We always insist on purchasing high quality raw matrials ,

introducing the advanced production and testing equipment from home

and abroad, adopting advanced production technology in order to

guarantee an excellent quality for every piece of products

delivered to customers.

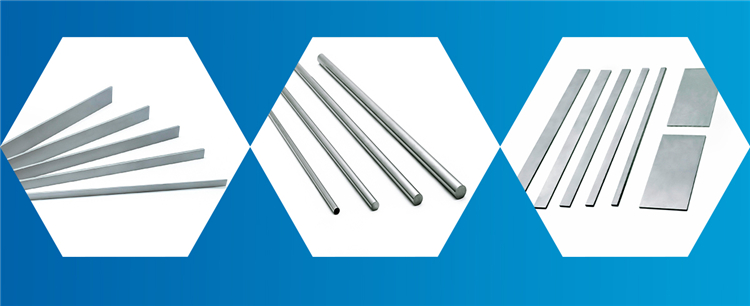

Today our company can provide a wide variety of products ranging

from saw tips,strips, and rods to other custom-made special parts

for customers from domestic and overseas.

To be your reliable business partner, we always aim to the strict

standards, the quality-first principles and the superior service to

meet your demands.

Grade Chart

| Grade | Density(g/Cm3) | Hardness(HRA) | T.R.S(N/mm2) | Recommended Cutting Applications | Proposal for welding |

| XF6 | 14.7-14.9 | 92.0-92.8 | ≥2600 | For solidwood,hardwood and composite board,etc. | Recommend the high-frequency welding |

| XF8 | 14.5-14.7 | 91.0-92.0 | ≥2800 | For construction formwork, Non-Ferrous Metal and various woodworking tools,etc. | Recommend the high-frequency welding |

| XF10 | 14.3-14.5 | 90.5-91.5 | ≥3000 | For solidwood,hardwood and various woodworking tools,etc. | Recommend the high-frequency welding |

| XK10 | 14.8-15.0 | 90.5-91.0 | ≥2400 | For solidwood,hardwood,etc. | Use resistance welding,and the temperature should be not too high |

| XK20 | 14.6-14.8 | 89.5-90.5 | ≥2600 | For softwood,solidwood,etc. | Use resistance welding,and the temperature should be not too high |

| YG11C | 14.3-14.5 | 87.0-88.0 | ≥2600 | For marble,granite and various mining tools,etc. | Recommend the high-frequency welding |

| SM07 | 14.8-15.0 | 93.2-93.6 | ≥3000 | For solidwood,hardwood,copper,aluminum,plywood,etc. | Recommend the high-frequency welding |

| SM10 | 14.2-14.4 | 91.5-92.0 | ≥3000 | For hardwood,Non-Ferrous Metal,PCB circuit board and various woodworking tools,etc. | Recommend the high-frequency welding |

| Product name | cemented carbide burr tungsten carbide rotary bur with strict quality control |

| Material | Head is carbide,shank is steel |

| Tooth | single cut,double cut,aluminum cut |

| Speed of tools | 8000-20000Tum/min |

| Grain Size(um) | 0.6/0.8/1.2/2/4 |

| Application | Widely used in machining iron,steel casing,carbon steel,alloy steel,stainless steel,hardened steel,coaluminium etc. |

The application of carbide burrs

Carbide Burrs Can be Used on Many Materials

Tungsten Carbide burrs can be used on many materials: metals

including steel, aluminum and cast iron, all types of wood,

acrylics, fibreglass and plastics. When used on soft metals such as

gold, platinum and silver, carbide burrs are ideal as they will

last a long time with no chipping or breaking.

Steel, Carbon Steel & Stainless Steel

in Europe market preferential prices tungsten carbide rotary burr with quality assurance

Ralated Products

Photo for certification and customer feedback

Product Packing

FAQ

1.Are you trading company or manufacturer?

we are factory.

2.What is your terms of payment?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%T/T

in advance, balance before delivery.

3.Can I get a sample before order if it is customized products?

Yes,we will send customized samples to confirm first, mass

production is only started by customer's approval.

4.Do you have stock for standard sizes?

Most of standard sizes we have in stock. You can check with our

sales manager.

5.I just have a sample,can you produce it for me?

Yes, we will much appreciate if you have the drawing and know the

material or application. If not, it doesn't matter, send us the

sample. We will check the material, make the drawing and produce it

for you.

6.Can I get a free sample?

We can offer a standard sizes sample below 50g. The over weight

need charge the cost. And we do not pay transport cost.

7.What kind of transportation can we use?

By air,by ocean,by express,by train. Whatever, any kind of

transportation can be choose.

8.Hong long will you need for production?

Usually, we need 15 to 35 days. For mass production, maybe 45 days.

9.Can you make stickers with our logo or laser logo on our

products?

Yes,we can.

For further information, don't hesitate to contact us.