Zhuzhou Chaoyu Industrial Co.,Ltd |

|

Tungsten carbide compressor shaft seal ring, Titanium carbide Seal

Ring or TC Seat

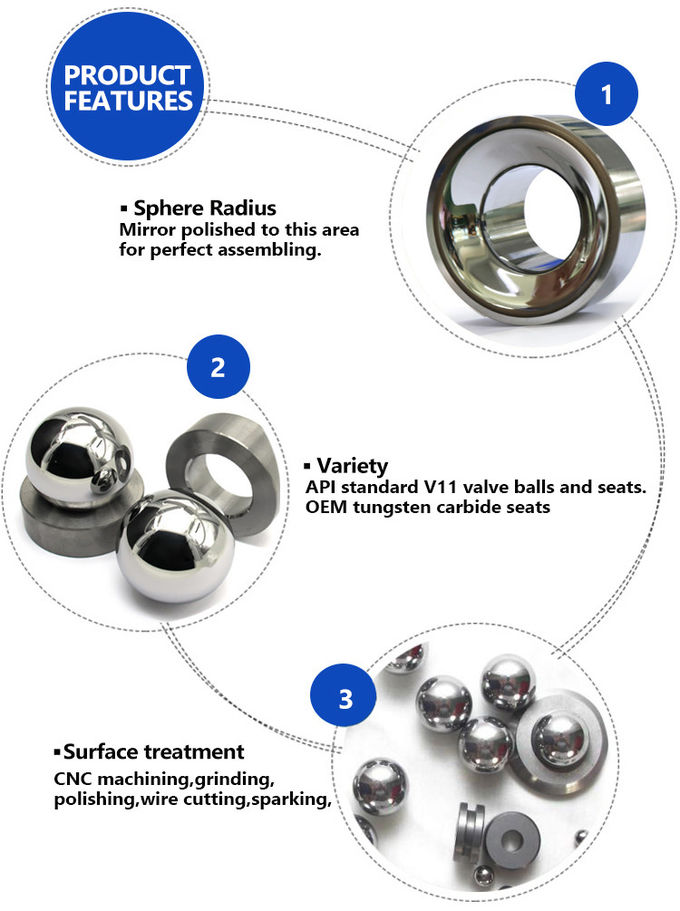

Features of TC seat

-Matched with a unique product called tungsten carbide hollow

ball,which is often used in oil and nature gas industry,If you are

interested in our hollow spheres, please contact with us.

-The TC Balls are manufactured as per Anti-Friction Bearing

Manufacturer Association (AFMBA) standards.

-Standard sized balls in 6% Cobalt material are readily available

in stock with us.

-These Tungsten Carbide Seats are used for various Oil Field

Equipment and Oilfield Valves such as Conventional Gas Lift Valves,

Wireline Retrivable (WLR) Injection Pressure Operated (IPO) Gas

Lift Valves etc.

Comparison of material on TC valve balls and seats

1.The three most common materials for balls and seats are Tungsten

Carbide, Nickel Carbide, and Titanium Carbide (balls only).

Tungsten Carbide is the industry standard and for good reason;

2.Tungsten carbide has proven itself over many years of service in

the field with excellent wear properties and has a cobalt binder.

3.Nickel Carbide has similar wear properties and has a nickel

binder,it is best suited to corrosive and/or wet environments.

4.Titanium Carbide is the relatively “new kid on the block”. It is

a highly alloyed material suitable for all environments. Titanium

Carbide has the advantages of being less expensive, easier to

grind, and weighs considerably less than the other two materials.

However, it is best suited for balls only, not seats.

Dimensions of solid TC seat

These specs are the most common dimensions in our factory,if you

can't find the one you need,please contact for more information.

| Sr. code | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| SD | 0.625 | 0.750 | 0.938 | 1.125 | 1.250 | 1.375 | 1.688 | 2.250 |

| D 0/-0.005 | 0.793 | 0.918 | 1.168 | 1.388 | 1.478 | 1.720 | 2.010 | 3.072 |

d | 0.460 | 0.550 | 0.670 | 0.825 | 0.960 | 1.060 | 1.310 | 1.700 |

h | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 |

Quality grade of TC seat

we offer a wide range of tungsten carbide seats for you to

choose,the main quality grade is

K30(YG8),YG11,YG10X.

| Grade | ISO grade | Grain size (um) | Binder | density (g/cm³) | Hardness (HRA) | T.R.S (N/m㎡) |

| YG6X | K10 | | 6 | ≥14.95 | ≥91.5 | ≥1880 |

YG8(C2)

| K30 | medium | 8 | ≥14.80 | ≥89.5 | ≥2020 |

| K40 | medium | 11 | ≥14.70 | ≥87.0 | ≥2600 |

| fine | 10 | ≥14.60 | ≥91.5 | ≥3200 |

Application of TC seat

For sealing of valves of oil pumps in petroleum industry's sand

containing wells, viscous oil wells, sea oil wells, high pressure

sulfur resistant oil wells, compatible Cemented Carbide valve

seats,etc.

Production of TC seat