ZHUZHOU APPLE CARBIDE TOOLS CO.,LTD. |

|

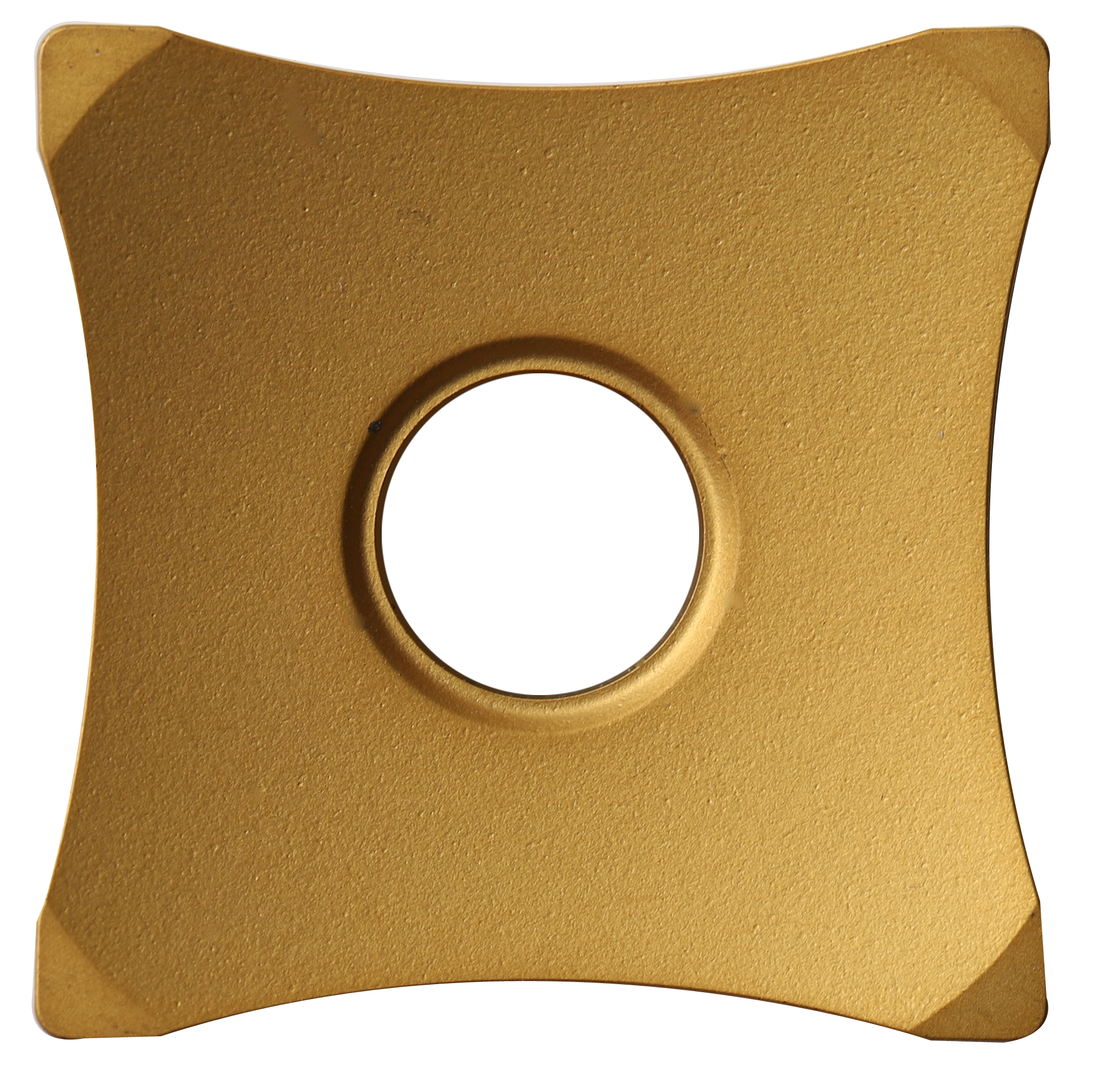

Tungsten Carbide 8 Edged SNMX1507 OD External Tube Scarfing Inserts Tools

What is tube scarfing?

The scarfing process need to be processed immediately after welding, so that the material could be removed relatively easily.

Therfore, it’s very important for scarfing tools and the corresponding inserts to be reliable and resist chipping and breaking of the cutting surface or the tool itself.

Model List of OD Scarfing Tools SNMX1507

| ||

| ITEM CODE | Machining Range (mm) | Cutting Edge Length(mm) |

| SNMX1507-R15 | 15-20 | 15 |

| SNMX1507-R20 | 20-25 | 15 |

| SNMX1507-R25 | 25-30 | 15 |

| SNMX1507-R30 | 30-35 | 15 |

| SNMX1507-R35 | 35-40 | 15 |

| SNMX1507-R40 | 40-50 | 15 |

| SNMX1507-R50 | 50-60 | 15 |

| SNMX1507-R60 | 60-90 | 15 |

| SNMX1507-R70 | 90-110 | 15 |

| SNMX1507-R80 | 110-130 | 15 |

| SNMX1507-R100 | 130-170 | 15 |

Grade Details of SNMX1507 Scarfing Inserts

| YC333 | Yellow | The combination of high strength and high toughness substrate with (MT-TiCN+thick AL2O3 + TiN )coating is the general brand of steel processing |

Advantages of DET OD Tube Scarfing Tools Inserts

A. Highest quality cutting edge------ provides extended tool life and superior surface finish

B.TiN + Al2O3 coating ------to suit for different scarfing applications, whether it is a high speed, high heat application or the run of the mill tube scarfing job.

Tips on reducing welding chatter

Welding chatter is the result of not being able to scarf the weld bead properly enough to achieve a good, clean tube.

A. An “ironing pass” can be used after the scarf stand. This stand “irons” out any imperfections the OD scarfing tool misses.

B. The scarfing tool relief should be set at an angle of at least 11 degrees from the work piece to prevent the OD scarfing tool from dragging on the tube.

C. The OD scarfing tool should be with a slightly larger radius than OD of the tube.

Other causes of Weld Chatter

a). Not enough weld bead for the scarfing tool to cut.

b). Not enough weld power to forge the weld properly.

c). The OD scarfing tool stand is located too far from the weld box causing the weld bead to cool down and not be cut smoothly.

d). The tube is jumping at the scarf point because there is no support plate or support roll under the scarfing tool.

e). Incorrect OD scarfing tool radius.

f). Dull, chipped, or worn scarfing tool.

After-sale service:

1. Can be refund if there is a quality problem

2. Technical support will be offered once you need

3. Accepting customer visiting