Zhuzhou Lizhou Cemented Carbide Co., Ltd. |

|

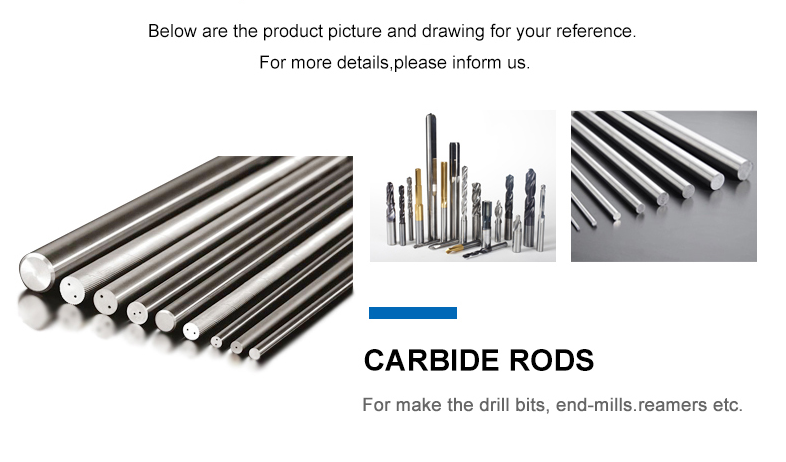

Unground Sintered Tungsten Carbide Bar 3mm To 40mm >=91.5

Hardness Heat Resistant

Description & Application:

Tunsten carbide rod as per it's application we mainly

recommend the below metioned grade for makeing different cutting

tool:

1. LX25 (make cutting tool HRC<=55):It is suitable for machining

common steel, cast iron, stainless steel, heat‐resistant steel ,

nickel based alloys and titanium alloys, etc. It is recommended for

making conventional tools, such as twist drills, end drills, screw

taps, etc.

2. LBC25(make cutting tool HRC<=60):It is suitable for machining

titanium alloy , heat resistant alloys, stainless steel, hardened

steel, grey cast iron, glass‐fiber Reinforced plastics, composite

materials, etc. It is recommended to make drills and milling tools,

etc.

3. . With several years development, our products have been

exported to Turkey, Russia, indial, isreal and so on, with the good

quality and competitive price. Our hard working attitude and

responsiveness are approved by our customers.

4. The standard size, we have many like D4/D6/D8/D10/D12 *

330mm length available in the stock, free sample is welcomed.

Recommended Grade:

| Grade | Grain size(μm) | Density(g/cm³) | Hardness(>=HRA) | TRS |

| LX25 | 0.8 | 14.5 | >=91.5 | >=3800 |

| LBC20 | 0.8 | 14.42 | >=91.5 | >=4000 |

| LBC25 | 0.6 | 14.03 | >=92.0 | >=4000 |

Unground Dimension and Tolerance

Dimension | Tolerance of diameter(mm) | Tolerance of length(mm) |

BL-Φ4.0×330 | +0.3/+0.5 | +0/+5.0 |

BL-Φ6.0×330 | ||

BL-Φ8.0×330 | ||

BL-Φ10.0×330 | ||

BL-Φ10.0×330 |

+0.30/+0.70

| +0/+5.0

|

BL-Φ12.0×330 | ||

BL-Φ14.0×330 | ||

BL-Φ16.0×330 | ||

BL-Φ18.0×330 |

+0.40/+1.0

| +0/+5.0

|

BL-Φ20.0×330 | ||

BL-Φ22.0×330 | ||

BL-Φ24.0×330 | ||

BL-Φ26.0×330 | ||

BL-Φ28.0×330 | ||

BL-Φ30.0×330 |

Production Process:

Below are the production processes of blank solid tungsten carbide

round bar, to ensure high quality, we assureed our customers that:

1. All materials are tested in terms of density, hardness and T.R.S

before use.

2. Every piece of product goes through in-process and final

inspection.

3. Every batch of product can be traced.

Our Guarantee:

1. high quality durable tungsten carbide welding rods/cemented rods

for milling for router bits made from 100% virgin raw material.

2. produced with advanced equipments and process.

3. all products go through in-process and final inspection.

4. free online technical service available.

5. stable and continuous production ability.