Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Professional Customization Cemented Tungsten Carbide Bushing /

Shaft Sleeves

The Details of tungsten carbide bushing

Tungsten carbide material features extreme wear resistance and

hardness. The material is typically forged by the reaction of

tungsten (W) metal and carbon (C) at 1400 to 2000. The result is a

grey powder that can be pressed and formed into virtually any

shape. When processing the powder into a shape, manufacturers use

either a nickel or cobalt-bonding agent. Several chemical

compositions can be used to provide better properties for varying

applications.

Properties of the 80-94% WC 6-20% Ni

Density : 13.8-15 g/cm3

Hardness : 81.5-89.5 HRA

Bending strength : 1500-2250 N/mm²

The Product Description Of Tungsten Carbide Bushing Sleeve For Pump

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at home and aboard.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing. Most of the specifications are all customized.

The Product feature of Tungsten Carbide Bushing Sleeve for Pump

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

Cemented carbide bushing made by virgin tungsten carbide material. It obtain high hardness and bending strength. It has superior performance on abrasion and corrosion resistance, which is widely used in many industries.

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at home and aboard.

In addition, as the various of application environment, There are several types of Tungsten carbide bushing. Most of the specifications are all customized.

Grade List

Grade | Density | T.R.S. MPa | Performance & application recommended |

YG6A | 14.95 | 1800 | Fine grain alloy, good wear resistance. Semi-finishing of chilled cast iron, non-ferrous metals alloys, semi-finishing and finishing of hardened steel, alloy steel. |

YG8 | 14.8 | 2200 | High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower |

YN8 | 14.7 | 2000 | Corrosion Resistant, It widely used in chemical and petroleum pumps |

YG10 | 14.5 | 2400 | High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower. Roughing of cast irons, non-ferrous metals and their alloys as well as non metallic materials at low cutting speed. |

YL10.2 | 14.5 | 2400 | Fine grain alloy, good wear resistance. Used for processing hard wood, veneer board, PCB, PVC and metals |

YG20 | 14.3 | 2420 | Conventional wear resistance, high bending strength,used for steel alloy etc. |

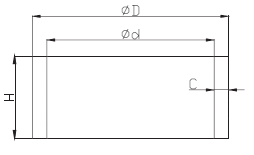

Details Carbide Bushing

| Deimensions of A Type Straight Sleeves (mm) | ||||

| Type No. | D | d | H | C |

| XA1 | 14.5-20 | 12.16 | 6.0-10.0 | 1.3 |

| XA2 | 12.5 | 3.5-7.0 | 12.7 | 4.5 |

| XA3 | 21-60 | 15-50 | 51 | 3 |

| XA4 | 75-130 | 60-115 | 55-100 | 6 |

| XA5 | 140-300 | 120-200 | 60-150 | 10 |

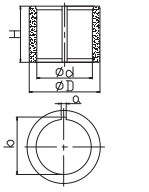

| Deimensions of A Type Straight Sleeves (mm) | |||

| D | d | C | H |

| 25.0-30.0 | 9.0-14.0 | 2.0-3.5 | 21.0-25.0 |

| 31.0-50.0 | 14.0-35.0 | 2.0-3.5 | 21.0-25.0 |

| 60.0-100.0 | 47.0-85.0 | 2.0-3.5 | 30.0-70.0 |

| Deimensions of A Type Straight Sleeves (mm) | |||

| D | d | H | a |

| 20.0-40.0 | 17.0-30.0 | 10.0-36.0 | 1.6 |

| 41.0-80.0 | 31.0-70.0 | 10.0-36.0 | 3.2 |

Product Application Scene

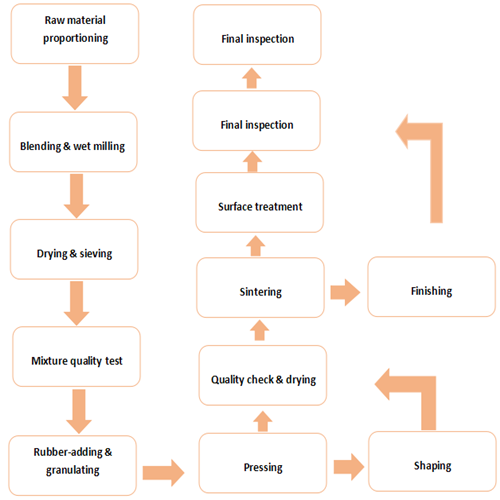

Production Process

FAQ

Q1: Is Xingyu trading company or manufacturer ?

A1: We are manufacture of tungsten carbide since established on 1998,specializing in carbide plates/bushings/rollers/special wear parts.

Q2: Has Xingyu acquired the foremost certification of ISO 9001?

A2: Xingyu has been endorsed with the ISO 9001 rating since 2008.

Q3: When can I get the offer after sending inquiry?

A3: We usually quote within 24 hours after we get your inquiry .If you are very urgent to get the price please call us or tell us in your email so that we will regard your inquiry priority.

Q4: Could Xingyu sales staff be reached anytime for assistance regarding orders or general enquire ?

A4: Our sales staff operates between 8am-5pm Monday to Saturday.