Zhuzhou Weikeduo Cemented Carbide Co., Ltd. |

|

Verified Suppliers

|

|

Special Cnc Carbide Inserts / Long Life Tungsten Carbide Jaw Inserts

Cnc Carbide Inserts Specifications

Cnc Carbide Inserts are the general name for indexable turning inserts and are the

mainstream products in modern metal cutting applications. Mainly

used in metal turning, milling, cutting and grooving, thread

turning and other fields.

CNC inserts are mainly used in metal turning, milling, cutting and

grooving, thread turning and other fields. According to the

material can be divided into coated blades, cermet blades,

non-metallic ceramic blades, carbide blades, super hard blades and

so on. It is characterized by high efficiency and high wear

resistance, which is more than 4 times more efficient than

traditional welding inserts and alloy inserts. With the continuous

advancement of coating technology, breakthroughs in key

technologies of wear resistance and high temperature resistance

will further improve efficiency and reduce processing costs.

Classification by use

(1) Turning tools can be divided according to their use.

(a) 90 degree turning tool (partial knife);

(b) 45 degree turning tool (elbow turning tool);

(c) Cutting knife;

(d) Boring cutters;

(e) Formed turning tools;

(f) Thread turning tools;

(g) Carbide non-grinding turning tools

(2) Basic uses of various turning tools

(a) 90 degree turning tool: used for turning the workpiece's

outer circle, step and end face.

(b) 45 degree turning tool: used for turning the workpiece's

outer circle, end face and chamfer.

(c) Cutting knife: used to cut the grooves cut out on the

workpiece or workpiece.

(d) Boring cutter: used for turning the inner hole of the

workpiece.

(e) Forming turning tools: used for turning fillets, grooves

or workpieces with special shapes at the step.

(f) Thread turning tool: used for turning threads.

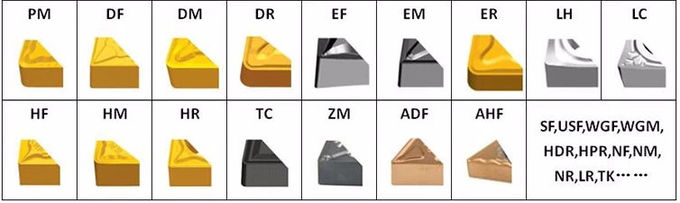

Chip breaker System

NO | Chip Breaker | Introduction | Competitor (Chip Breaker) |

1 | PM | Double sided chip breaker for medium machining. Wide range of application in steel and cast iron. | (PM) |

2 | DF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. | (-PF), SECO(-MF1) |

3 | DM | Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. | (PM), SECO(MF2), KYOCERA(HQ) |

4 | DR | Double sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. | (PR,QR) |

5 | EF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. | KYOCERA(-CF) |

6 | EM | Double sided chip breaker with sharp cutting edge and large rake angle. Process reliable medium machining of stainless steel. | TUNGALOY(TM) |

7 | ER | Double sided chip breaker with large rake angle for low cutting forces. Suitable for roughing of stainless steel. | (MR,QR) |

8 | LH | Single sided chipbreaker for machining of cast aluminium alloys. Sharp cutting edge with positive rake angle. G-tolerance for high repeatability. | KORLOY(AR) |

9 | LC | Single sided chip breaker with excellent cutting edge design. Sharp cutting edge with positive rake angle. G-tolerance for | KORLOY(AK) |

10 | HF | Single sided chip breaker with good chip control. Suitable for finishing to medium machining of steel and cast iron. | MITSUBISHI (FJ,FV), KYOCERA(CF) |

11 | HM | Single sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. | MITSUBISHI (FJ,FV), KYOCERA(CF) |

12 | HR | Single sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. | (MR,QR,PR) |

13 | TC | Double sided chip breaker with surrounding cutting edge. Process reliable machining due to highest cutting edge stability. | MITSUBISHI (GH) |

| ... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

| No. | Grade | Grade description | Grade(Competitors) |

| 1 | YBC152 | CVD coated P10–P20 carbide grade for finishing to medium operation of steel and casting steel. Outstanding performance under higher cutting speed and temperature with excellent wear resistance. | GC4315(), E6020(MITSUBISHI), T9125(TUNGALOY) |

| 2 | YB6315 | CVD coating grade combining nano dioxygen gradient transition techniques and crystal nucleus pre-insertion techniques. | GC4315(), T9115(TUNGALOY) |

| 3 | YBC252 | CVD coated P20–P35 carbide grade for medium operation to roughing of steel and casting steel. Optimal performance of wear resistance and toughness for a wide application field. | GC4325(),E6020(MITSUBISHI),T9125(TUNGALOY) |

| 4 | YBD102 | CVD coated K05–K20 carbide substrate. Optimized for medium operation of cast iron, special nodular cast iron and hard steel at high cutting speed. | UC5115(MITSUBISHI) |

| 5 | YBD152 | CVD coated K10–K25 carbide substrate. Optimized for medium to roughing operation of cast iron. Good wear resistance and toughness at higher cutting speed. | UC5115(MITSUBISHI) |

| 6 | YBD152C | Thick Al2O3 CVD coated K05–K25 carbide substrate. Optimized for medium to roughing operation of cast iron.Higher wear resistance and toughness at higher cutting speed in combination with TC chip breaker. | UC5115(MITSUBISHI) |

| 7 | YB7315 | CVD coated K10–K25 carbide substrate. Optimized for medium to roughing operation of cast iron. Improved wear resistance and toughness at high cutting speed. | UC5115(MITSUBISHI), WAK20() |

| 8 | YBM153 | CVD coated M10–M25 carbide grade for fnishing to medium application in stainless steel. High wear resistance and capability against plasctic deformation at higher cutting speed. | |

| 9 | YBM253 | CVD coated M15–M35 carbide grade for medium to roughing operation in stainless steel with wide application field. High wear resistance and capability against plasctic deformation at higher cutting speed. | |

| 10 | YBG202 | PVD coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel and steel (milling). Good wear resistance in a wide application field. | |

| 11 | YBG205 | PVD multilayer coated M20–M40/S15–S25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (milling). Good wear resistance and thermal stability in a wide application field. | VP15TF(MITSUBISHI) |

| 12 | YB9320 | PVD multilayer coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (grooving/milling).Optimized coating stability for higher wear resistance and thermal stability in a wide application field. | |

| 13 | YNT251 | Uncoated P10–P25 cermet grade for fine finishing to medium operation of steel and stainless steel. Good wear resistance and toughness. Suitable also in light interrupted cut. | |

| ... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

Full Specification

| CCMT | SCMW | SECN | TEEN | VNMA | ODEW | DHD |

| CCMW | SCGW | SEGN | TECN | VBMW | XEEN | MP |

| CNMA | SNMA | SNGA | TEEW | VCMW | EDR | G25 |

| CCGW | SNGN | TPGH | TECW | VNMG | SDR | ADEW |

| CNMN | SNMN | TCGW | RNMN | VNMP | DED | TEEW |

| CPMN | SPMN | TPGN | RNGN | VPGA | DGD | SDEN |

| DCGW | SPGN | TNMA | REEN | VPGR | DFD | SEEN |

| DNMA | SPCN | TEHW | RCMN | WNMA | ... .. | |

USF groove description: G-class accuracy, large front angle design, sharp cutting edge, faster cutting, is the preferred groove for precision turning of small shaft parts.

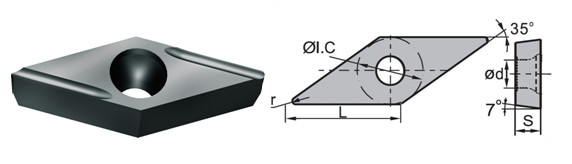

| TYPE | S | Φd | r | |||

| VPGT080201L-USF | 2.43 | 2.3 | 0.1 | |||

| VPGT080201R-USF | 2.38 | 2.3 | 0.1 | |||

| VPGT080202L-USF | 2.43 | 2.3 | 0.2 | |||

| VPGT080202R-USF | 2.38 | 2.3 | 0.2 | |||

| VPGT110301L-USF | 3.18 | 2.8 | 0.1 | |||

| VPGT110301R-USF | 3.18 | 2.8 | 0.1 | |||

USF groove description: G-class accuracy, large front angle design, sharp cutting edge, faster cutting, is the preferred groove for precision turning of small shaft parts.

| TYPE | S | Φd | r | |||

| VCGT080201L-USF | 2.38 | 2.3 | 0.1 | |||

| VCGT080201R-USF | 2.38 | 2.3 | 0.1 | |||

| VCGT080202L-USF | 2.38 | 2.3 | 0.2 | |||

| VCGT080202R-USF | 2.38 | 2.3 | 0.2 | |||

| VCGT110301L-USF | 3.18 | 2.8 | 0.1 | |||

| VCGT110301R-USF | 3.18 | 2.8 | 0.1 | |||

| VCGT110302L-USF | 3.18 | 2.8 | 0.2 | |||

| VCGT110302R-USF | 3.18 | 2.8 | 0.2 | |||