Chengdu Fengke Precision Tool Co., Ltd. |

|

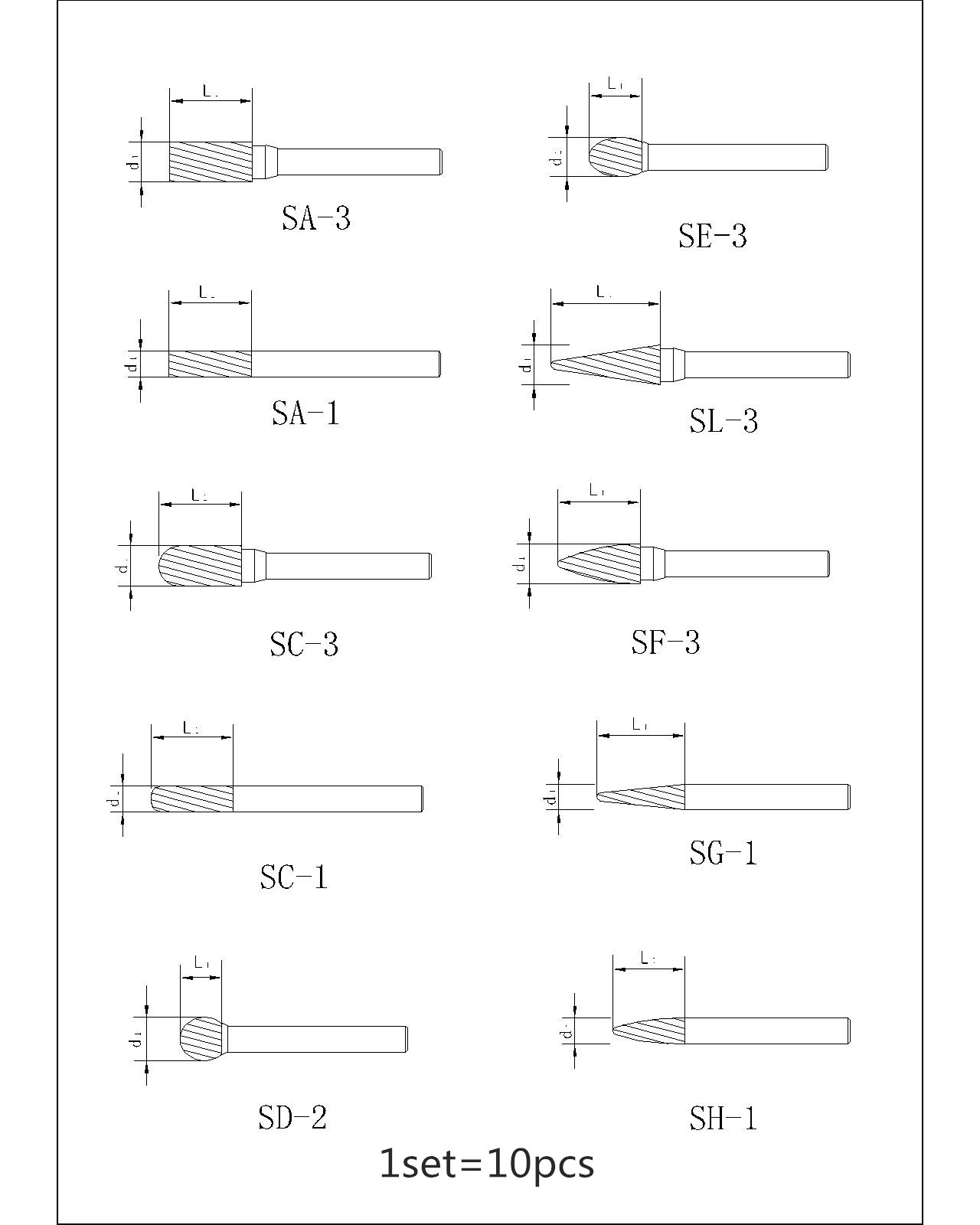

Cylinder Shape Shank Diameter 6mm Tungsten Carbide Bur

Application

(1) Finish machining various metal mold cavities, such as shoe

molds, etc.

(2) All kinds of metal and non-metal craft carving, craft gift

carving.

(3) Clean up flashes, burrs, and welds of cast, forged, and welded

parts, such as machine foundries, shipyards, and automobile

factories.

(4) Chamfer rounding and groove processing of various mechanical

parts, pipe cleaning, and finishing of the inner hole surface of

mechanical parts, such as machinery factories and repair shops.

(5) Trimming the part of the impeller runner, such as automobile

engine factory.

Product Description

| Material | 100% Tungsten Carbide Raw Material |

| Grade | YG6/YG6C/YG8/ |

| Density | 14.60-14.8g/cm³ |

| Application | weld preparation, weld smoothing, deburring, chamfering, deflashing, and scale removal, wood carving, farriers, metalsmithing |

| Hardness | 91.4-94 HRA |

| TRS | 2400-2800MPA |

What should we pay attention to when we use it?

1. Speed /RPM

The speed at which you use your carbide burrs in your rotary tool will depend on the material you're using it on and the contour being produced but it's safe to say you do not need to exceed speeds of 35,000 RPM.

2. Apply only a little pressure

As with all drill bits and burrs, let the burr do the work and apply only a little pressure otherwise the cutting edges of the flutes will chip away or become smooth too quickly, reducing the life of your burr.

3. Keep The Carbide Burr On The Move

When using your carbide burr try not to keep it still for too long as this will prevent the burr from digging and jabbing into your material causing unsightly marks and roughness.

** Carbide burrs manufactured to your drawings to meet your demands of

particular stock removal.

How to produce the Carbide burs?