Wuhan Qiaoxin Refrigeration Equipment CO., LTD |

|

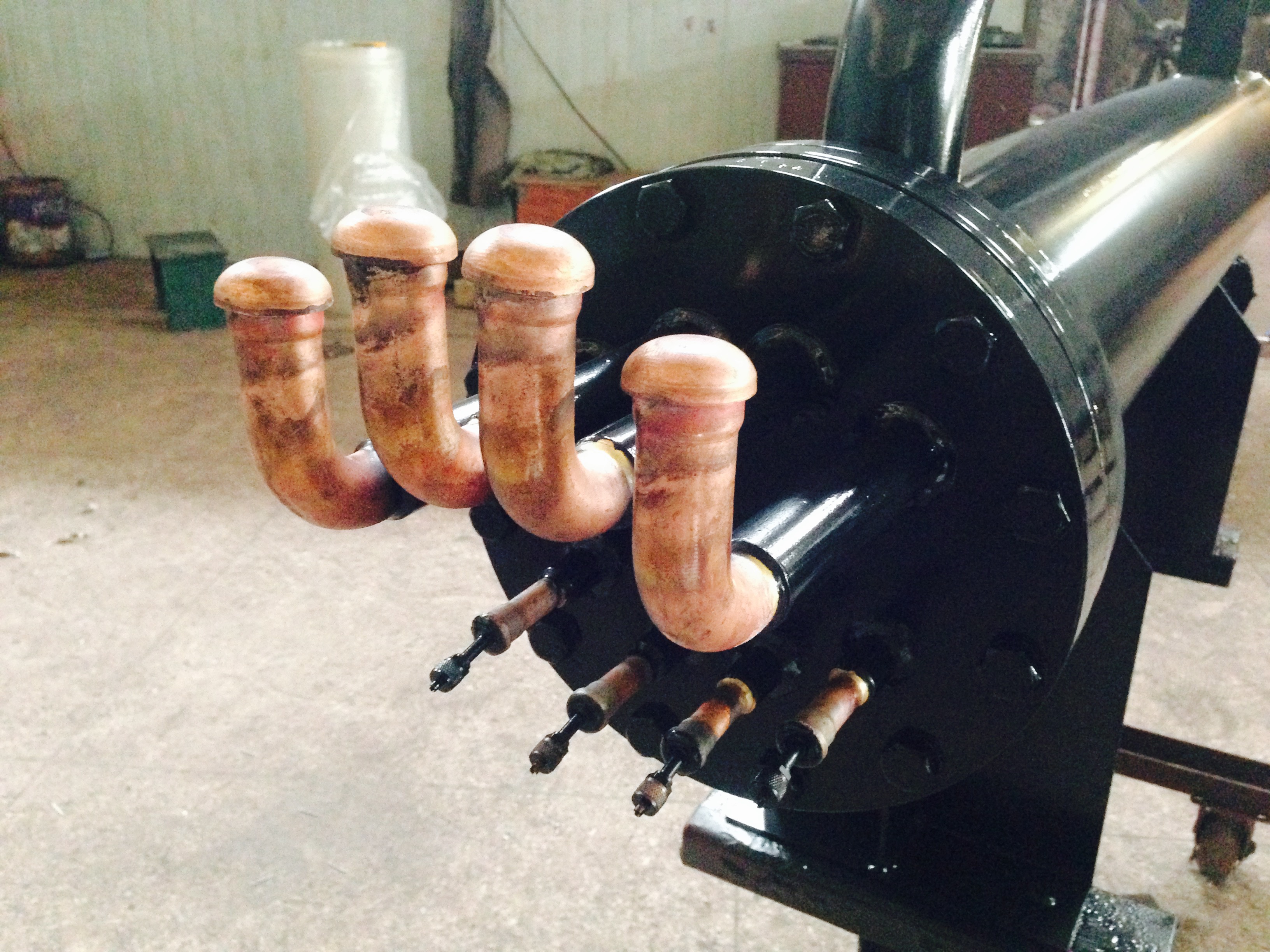

Water - Cooled Condensing Unit

Shell and Tube Heat Exchanger Evaporator

Shell and tube heat exchanger materials are generally carbon steel, stainless steel and copper-based, in

which carbon steel tube plate as a cooler, the tube and tube pipe welds often appear corrosion leakage,

spill into The cooling water system pollutes the environment and causes material waste.

Shell and tube heat exchanger in the production, the tube and the

tube of the general use of manual arc

welding, weld shape there are different degrees of defects, such as depression, pores, slag, etc., the

distribution of weld stress is not uniform. When used in the tube part of the general contact with the

industrial cooling water, and industrial cooling water impurities, salts, gases, microorganisms will constitute

the tube and weld corrosion, which is what we often say electrochemical corrosion. Studies have shown

that industrial water, whether fresh or seawater, will have a variety of ions and dissolved oxygen, which

chloride ion and oxygen concentration changes, the corrosion of metal plays an important role in the

shape. In addition, the complexity of the metal structure will also affect the corrosion pattern. Therefore,

the corrosion of the tube plate and the pipe weld is mainly pitting corrosion and crevice corrosion. From

the outside, the tube plate surface will have many corrosion products and accumulation of objects, the

distribution of the size of the pit. When the sea water as the medium, but also produce galvanic corrosion.

Chemical corrosion is the corrosion of the medium, the heat exchanger tube board contact with a variety

of chemical media, will be subject to chemical corrosion. In addition, the heat exchanger tube plate and

the heat transfer tube will produce a certain degree of bimetallic corrosion.

In summary, the main factors affecting the corrosion of shell and tube heat exchanger are:

(1) medium composition and concentration: the impact of different concentrations, for example, in

hydrochloric acid, the greater the general concentration of the more serious corrosion. Carbon steel and

stainless steel in the concentration of about 50% of the sulfuric acid corrosion in the most serious, and

when the concentration increased to 60% or more, the corrosion but a sharp decline;

(2) Impurities: Hazardous impurities include chloride, sulfur, cyanide, ammonia, etc. These impurities can

cause severe corrosion in some cases

(3) temperature: corrosion is a chemical reaction, the temperature of each increase of 10 ℃, corrosion

rate increased by about 1 to 3 times, but there are exceptions;

(4) ph value: the general ph value is smaller, the greater the corrosion of metal;

(5) flow rate: the greater the flow rate in most cases, the greater the corrosion.

STRAIGHT SINGLE SERIES DRY SPIRAL BAFFLE PLATE EVAPORATOR

CAPACITY: 750KW TO 1500KW

| Models | RE750S14 | RE900S16 | RE1100S16 | RE1240S20 | RE1360S20 | RE1420S20 | RE1500S20 | ||

Rated data Refrigerant R22 ti=12°C te=2°C tu=7°C Dts=5°C | Qn | KW | 750 | 900 | 1100 | 1240 | 1360 | 1420 | 1500 |

| Kcal/h(×103 ) | 700 | 862 | 983 | 1076 | 1169 | 1258 | 1367 | ||

| Wn | m3 /h | 121 | 141 | 168 | 230 | 252 | 261 | 289 | |

| Wm | m3 /h | 136 | 158 | 176 | 261 | 275 | 309 | 328 | |

| Dpn | bar | 0.48 | 0.54 | 0.48 | 0.40 | 0.46 | 0.49 | 0.58 |

| Models | RE750S14 | RE900S16 | RE1100S16 | RE1240S20 | RE1360S20 | RE1420S20 | RE1500S20 | |

| Dimension(mm) | A | 170 | 170 | 170 | 190 | 190 | 190 | 190 |

| B | 377 | 426 | 426 | 480 | 480 | 480 | 480 | |

| C | 3000 | 2860 | 3000 | 2860 | 2860 | 3000 | 3500 | |

| D | 460 | 530 | 530 | 600 | 600 | 600 | 600 | |

| E | 400 | 450 | 450 | 500 | 500 | 500 | 550 | |

| F | 3086 | 2984 | 3124 | 2984 | 2984 | 3124 | 3624 | |

| Vent | S1 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

| Outlet | S2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

| Connection | W(DN) | 150 | 150 | 150 | 200 | 200 | 200 | 200 |

| D1(mm) | 42 | 42 | 42 | 54(2) | 54(2) | 54(2) | 54(2) | |

| D2(mm) | 92 | 92 | 92 | 108 | 108 | 108 | 108 | |

| P(kg) | 706 | 753 | 808 | 863 | 921 | 992 | 1069 | |

Qn-rated refrigerating capacity Wn-cooling water flow Wm-maximum cooling water flow Dpn-pressure drop of recirculating cooling water Dts-overheat temperature | ||||||||

OIL SEPARATOR

CAPACITY 50L TO 200L

| Models | L | Dimension (mm) | Kg | ||||||

| A | B | C | D | D1 | E | F | |||

| QXYFQ50L | 50 | 600 | 280 | 180 | 325 | 273 | 390 | 420 | 90 |

| QXYFQ75L | 75 | 650 | 300 | 200 | 325 | 273 | 438 | 460 | 120 |

| QXYFQ95L | 95 | 650 | 320 | 220 | 377 | 325 | 462 | 500 | 142 |

| QXYFQ120L | 120 | 750 | 350 | 250 | 426 | 355 | 492 | 550 | 168 |

| QXYFQ150L | 150 | 800 | 400 | 300 | 480 | 377 | 410 | 560 | 190 |

| QXYFQ170L | 170 | 950 | 480 | 380 | 530 | 426 | 638 | 700 | 258 |

| QXYFQ200L | 200 | 1180 | 480 | 380 | 530 | 426 | 868 | 930 | 286 |

| Models | Corresponding cooling capacity | INLET a | OUTLET b | Return opening k |

| KW | Copper tube external diameter (mm) | Copper tube external diameter (mm) | Copper tube external diameter (mm) | |

| QXYFQ50L | 150-250 | 54 | 54 | 16 |

| QXYFQ75L | 260-450 | 67 | 67 | 16 |

| QXYFQ95L | 460-650 | 80 | 80 | 19 |

| QXYFQ120L | 660-850 | 92 | 92 | 19 |

| QXYFQ150L | 960-1150 | 105 | 105 | 19 |

| QXYFQ170L | 1160-1350 | 105 | 105 | 19 |

| QXYFQ200L | 1360-1600 | 133 | 133 | 19 |

COMPANY IMAGE

COOPERATED CLENTS